Leak detector type LAG 2000 A

24 / 28

part no. 15 071 53 e

When the leak has been repaired and the system restarted

•

The red light

A3

on the display unit and, if connected,

on the 2nd display unit goes out again.

•

Press

A2

and set to "On".

•

Replace the seal on

A2

:

Green light

A1

is lit again.

The display unit and, if connected, the 2nd display

unit again operates as intended in the tank system.

TROUBLESHOOTING

Fault cause

Action

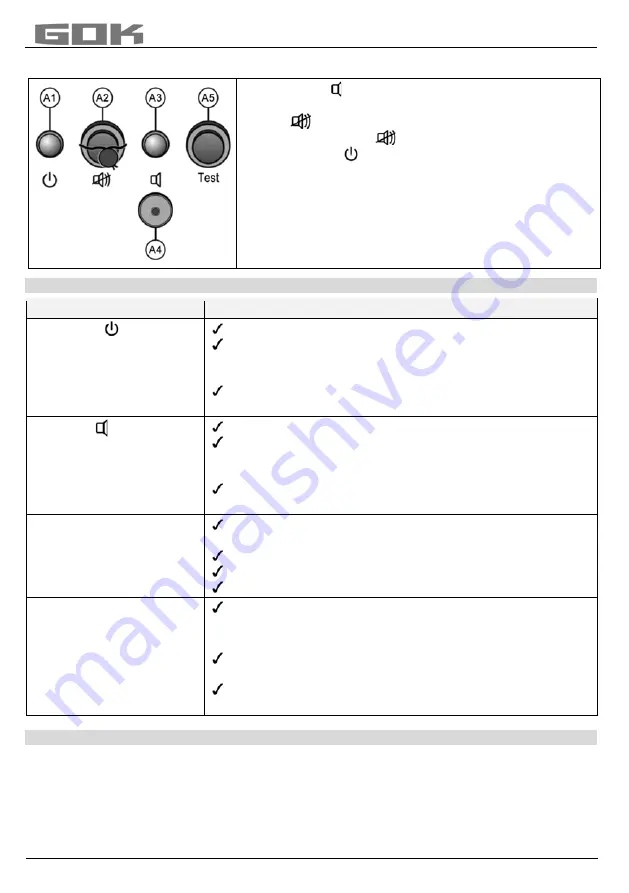

Green light A1 is not lit

Check the power connection.

If the fault cannot be found through the activities described

in CARE AND MAINTENANCE, replace the leak detector

with a new one.

Do not repair the display unit yourself, send it to the

manufacturer.

„Red light

A3

is lit and

the alarm buzzer

A4

is

triggered

without leak on

sensor unit / sensor cable

Check the sensor cable for breaks.

If the fault cannot be found through the activities described

in CARE AND MAINTENANCE, replace the sensor unit

with a new one.

Do not repair the sensor unit yourself, send it to the

manufacturer.

No leak detector liquid

flows from the check valve

Dismantle the connection line between the monitoring

space and the LDL tank and check for contamination.

Dismantle the check valve and check for contamination.

If necessary, clean the monitoring space .

Add new leak detector liquid.

Contaminated leak

detector liquid

Replace the leak detector liquid, making sure that it is an

approved liquid and that it is mixed with water in the correct

ratio.

Before filling with leak detector liquid, read the safety data

sheet (SDS) under all circumstances.

Comply with all safety information, as described under

“Filling the leak detector liquid”!

MAINTENANCE

The functions and operating safety of the LAG 2000 A must be checked at least once per

year or after maintenance or repair by a specialised company (see SAFETY INFORMATION)

or by the operator's qualified personnel.