Grand and Twin Grand

2848, 2860, and 2873 (32 oz. Pop-O-Golds)

Pop-O-Gold & Medallion (-100 Series)

2948, 2960, and 2973 (52 oz. Medallions)

Page 21

gmpopcorn.com

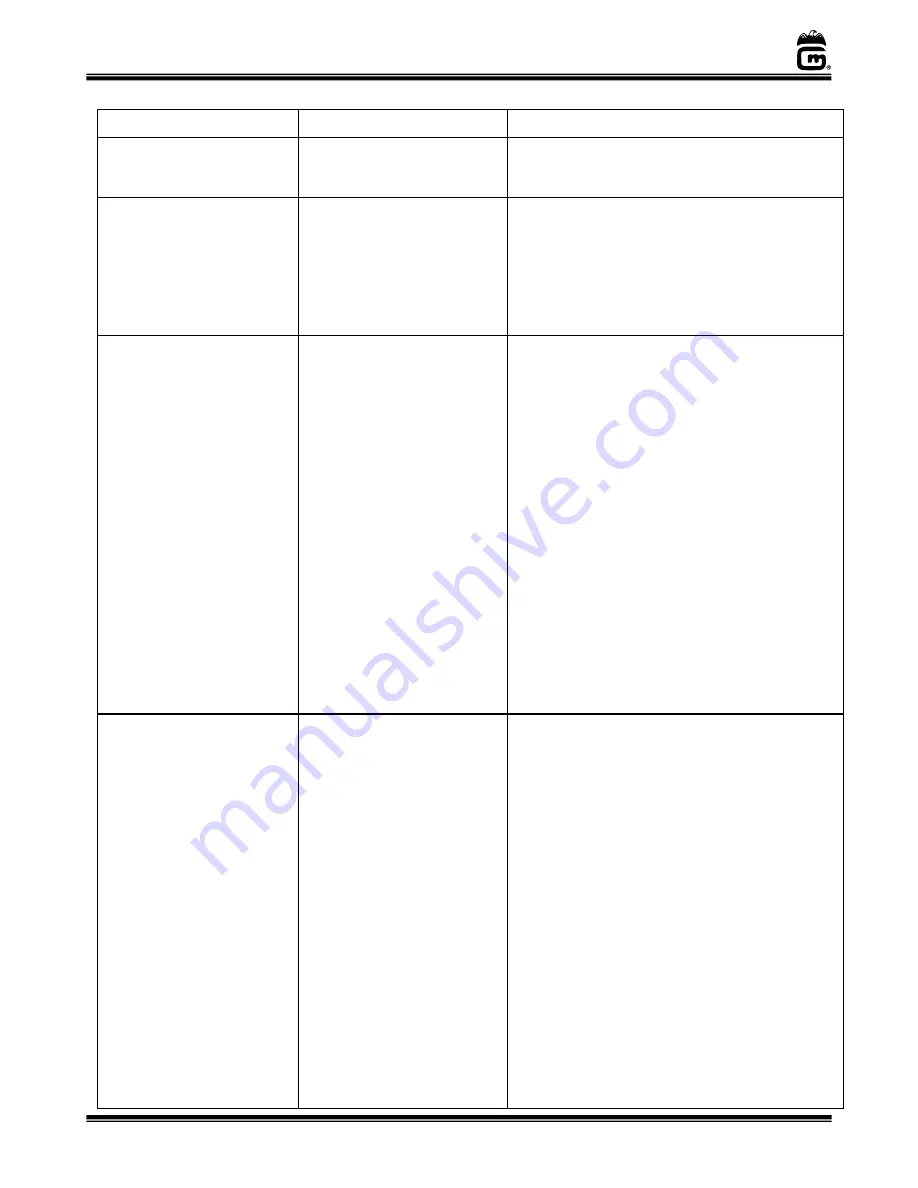

Issue

Possible Cause

Solution

E.

Heating Element

E.

Heating element in the kettle may be burned

out. Check with a qualified service person for

inspection/repair.

Oil Pump Does Not Deliver

Oil to Kettle

(for units

equipped with oil)

A.

Mini Circuit Breaker(s) on

popper tripped (if

equipped)

A.

Check the Mini Circuit Breaker(s); if reset,

then trips again, the unit must be inspected/

repaired by qualified service personnel.

B.

Oil Dispense Unit

B.

For additional possible causes/solutions,

reference the Troubleshooting section of the

Oil Dispense Unit Manual.

Long Popping Cycles

(Longer than 4 minutes for

Salt Popcorn; longer than 6

minutes for Sweet Popcorn)

A.

Heating Element

A.

For units with multiple elements in the kettle,

one of the heating elements in the kettle may

be burned out. This would result in the kettle

never reaching the proper operating

temperature. Check with a qualified service

person for inspection/repair.

B.

Low Voltage

B.

If the machine is operated on low voltage, this

could cause the kettle not to reach the proper

operating temperature. Check with a qualified

electrician.

C.

Inadequate Supply Lines

C.

Inadequately sized electrical supply lines, in

addition to being a fire hazard, would also

prevent the kettle from reaching the proper

operating temperature. Check with a qualified

electrician.

D.

Inferior Corn

D.

Inferior quality corn would result in longer

popping cycles. Use only top quality hybrid

popcorn from reputable suppliers. Even then,

if you let your corn pick up moisture or dry

out, your popping cycles will be slow.

Kettle Agitator Shaft not

Rotating

A.

Mini Circuit Breaker(s) on

popper tripped

(if equipped)

A.

Check the Mini Circuit Breaker(s); if reset,

then trips again, the unit must be inspected/

repaired by qualified service personnel.

B.

Kettle Motor Switch

B.

If the kettle agitator shaft is not rotating,

DO NOT

pop corn. Make sure the Kettle Motor

Switch is ON. If the switch is ON, and the shaft

is not rotating, the switch or motor may be

faulty, contact qualified service personnel for

inspection/repair.

C.

Kettle Agitator Shaft/Stir

Blade not rotating.

(Unit

must be OFF, unplugged

and cool prior to

checking or adjusting

the agitator assembly.)

C.

If the kettle agitator shaft is not rotating,

DO NOT

pop corn.

a.

Kettles with a FIXED Stir Rod

–

check the

clearance between the shaft with welded

stir blade and the kettle bottom; it should

be a minimum of 1/32”

(1 mm) (thickness of

a dime).

To make shaft adjustments, reference the

Agitator Set Collar Adjustment section.