Grand and Twin Grand

2848, 2860, and 2873 (32 oz. Pop-O-Golds)

Pop-O-Gold & Medallion (-100 Series)

2948, 2960, and 2973 (52 oz. Medallions)

Page 43

gmpopcorn.com

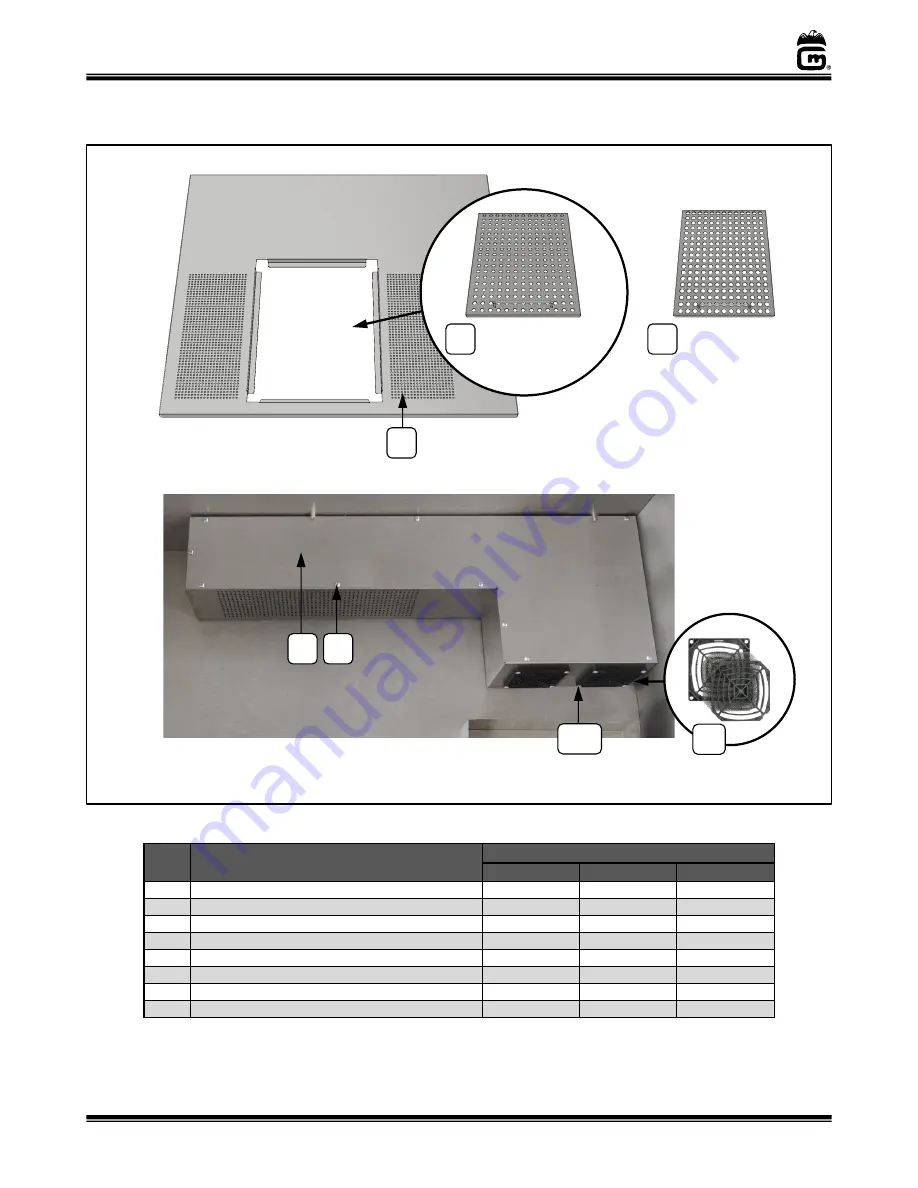

Corn Pan and Blower Box Exterior View

Item

Part Description

Part Number

48”

60”

72”

1

CORN SCREEN BASE

115464

115465

115466

2

CORN SCRN INS W/HNDL .375

115422

115422

115422

3

CORN SCRN INS W/HNDL .5

115423

115423

115423

4

TOP PLATE

63550

63550

63550

5

8-32 X 3/8 PHIL PAN HEAD

87515

87515

87515

6

FILTER AND GUARD ASSY

63707

63707

63707

7

8-32X5/8 FL HD PH MS

20067

20067

20067

8

8-32 SERRATED FLANGE NUT

61151

61151

61151

Blower Box Exterior View

(Under Corn Pan)

Corn Pan View

5

4

7, 8

6

Mushroom Corn

Screen Insert

(0.5

”

holes)

3

1

Butterfly Corn

Screen Insert

(0.375

”

holes)

2