Mighty–Mite

A

LL

M

ODELS

#2035

4

MAINTENANCE INSTRUCTIONS

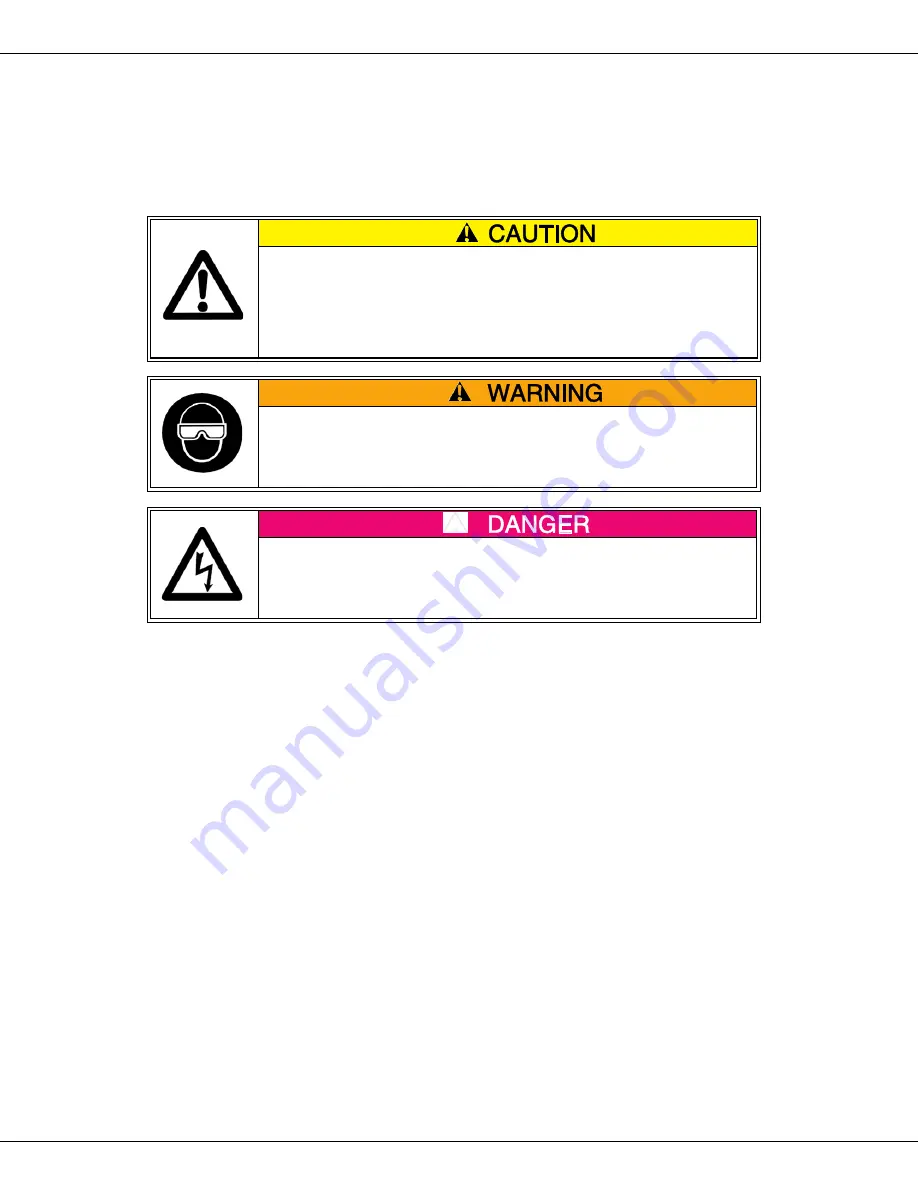

THE FOLLOWING SECTIONS OF THIS MANUAL ARE IN-

TENDED ONLY FOR QUALIFIED SERVICE PERSONNEL WHO

ARE FAMILIAR WITH ELECTRICAL EQUIPMENT. THESE ARE

NOT INTENDED FOR THE OPERATOR.

Adequate eye protection must be used when servicing this

equipment to prevent the possibility of injury.

Do NOT immerse the equipment in water.

Unplug your machine before servicing.

LUBRICATION REQUIREMENTS

DRIVE MOTOR

This is a sealed bearing type motor and requires no lubrication.

GAS CONVERSION

1. Disconnect the power supply at the fuse box or breaker.

2. Turn off the gas supply.

3. Refer to drawing number D-5019.

4. Place the kettle in the dump position. Remove the retainer screws. Remove the burner

(Part No. 74558) to expose the burner orifice hood. Replace the main burner hood with the

appropriate part number for the intended type of gas.

A. Part # 74629 (#61) for LP gas.

B. Part # 74630 (#53) for Natural Gas.

5. Replace the pilot burner orifice with the appropriate part number for the intended type of

gas.

Pilot Burner Part No. 74028

A. Part No. 74029 (.011 Dia. Holes) for “LP” Gas.

B. Part No. 74531 (.018 Dia. Holes) for Natural Gas. (“NAT”)

Pilot Burner Part No. 57031

A. Part No. 74029 (.011 Dia. Holes) for "LP” Gas.

B. Part No. 74030 (.023 Dia. Holes) for Natural Gas. (“NAT”)

6. Remove the hex cap on the pressure regulator and position the appropriate end of the red

plug down. “LP” for Liquefied Petroleum Gas, and “NAT” for Natural Gas. Replace the

hex cap. (Instructions continued next page.)

a

Summary of Contents for Mighty-Mite 2035BG

Page 2: ...GAS SAFETY PRECAUTIONS ...

Page 8: ...Mighty Mite ALL MODELS 2035 6 BASO VALVE INFORMATION ...

Page 9: ...Mighty Mite ALL MODELS 2035 7 BASO VALVE INFORMATION continued ...

Page 10: ...Mighty Mite ALL MODELS 2035 8 KETTLE CROSS SECTION ASSEMBLY ...

Page 12: ...Mighty Mite ALL MODELS 2035 10 CABINET ASSEMBLY ...

Page 15: ...Mighty Mite ALL MODELS 2035 13 ELECTRICAL SCHEMATIC ...

Page 16: ...Mighty Mite ALL MODELS 2035 14 ELECTRICAL SCHEMATIC MODEL 2035DC ONLY ...