15

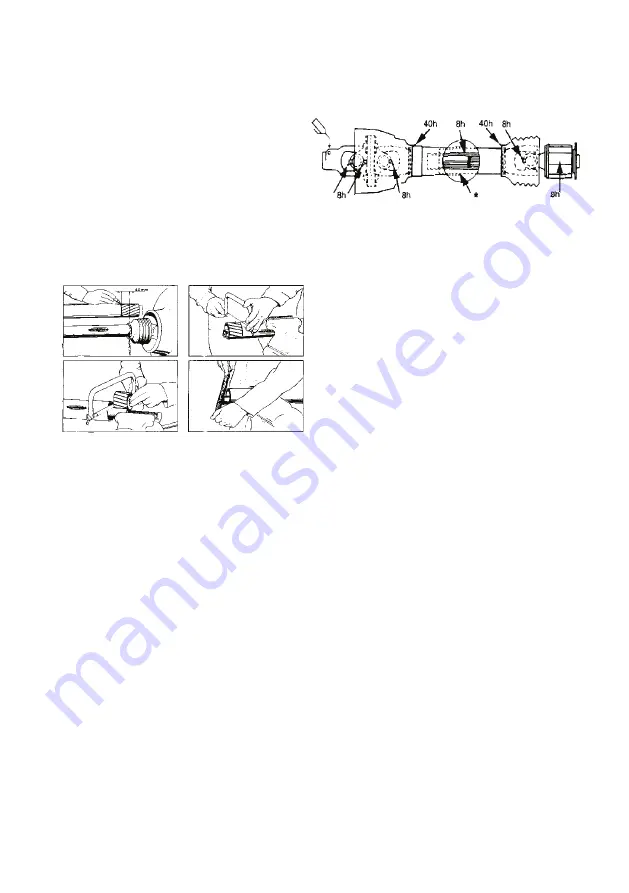

PTO Shaft Length Adjustment

To adjust the length:

1 Hold the half-shafts next to each other in

the shortest working position and mark

them.

2 Shorten inner and outer guard tubes

equally.

3 Shorten inner and outer sliding profiles by

the same length as the guard tubes.

4 Round off all sharp edges and remove

burrs.

5 Grease sliding profiles before

reassembling.

CAUTION:

When attaching shaft to sprayer

and tractor, always ensure all guard covers

are in place. Operate the PTO slowly when

the PTO shaft is first attached to assess

installation. Care should be taken when

engaging the clutch so that sudden loading,

which can result in pump damage and gear

wear, is avoided. Ideally the pump should start

from zero pressure. It is essential to maintain

lubrication schedule while PTO shaft is in use.

PTO Shaft Lubrication

Proper grease is essential for the sprayer to

operate with maximum effectiveness and life-

expectancy.

CAUTION:

Never lubricate the PTO shaft while it is

running. It is important to keep the lubricant

and lubricant applicator clean. Wipe all

dirt from the fittings before use. Goldacres

recommends that multi-purpose grease should

be used for all lubrications.

The figures mentioned below refer to the

frequency (in hours) of lubrication for the

respective grease nipple locations.

• Pull shaft apart - apply grease to inside of

outer Telescopic profile

6. Check pump oil level prior to engaging

PTO.

7. Fill the tank with a quantity of water

sufficient to test spray unit for leaks.

8. Unfold the boom as per the boom folding

instructions in this manual

9. Make sure the pressure relief valve is

backed off prior to engaging PTO.

10. Visually check that all fittings are in place

and secure and taps are in working

positions.

11. Ensure that all taps are in the off position

and bypass back to tank is open. All boom

taps should be in the off position.

IMPORTANT:

Do not run diaphragm pumps

above 540 RPM.

12. To start the pump, engage the PTO at the

lowest revs possible and then gradually

increase revs until the pump reaches its

operating speed.

13. Set the pressure relief valve to the desired

spraying pressure. Once PTO has been

engaged and is running at 540RPM.

14. Gradually turn on individual boom

sections, until all sections are engaged.

15. Adjust pressure to suit desired spraying

rate.

16. Run unit at operating speed until contents

of tank are dispersed.

17. Take note of any water leaks, and tighten

fittings to rectify the problem immediately.