14

General Information &

Specifications

General

The tray mount sprayer is ideal for small

acreage and hard to get areas. The Pro-Reel

Traymounts feature engine driven diaphragm

pumps with pressure ranges from 290–560

Psi.

Our tray mount range are durable with a steel

frame and our tanks are industrial grade UV

protected polyethylene. Our range can be

fitted with a host of booms and other handy

options to make your spraying tasks easier.

Know Your Sprayer

Getting to know your sprayer prior to operation

is crucial in the safe and efficient operation

of this equipment. Take the time to familiarise

yourself with all the standard and optional

components fitted to your sprayer, not only do

you need to know where key components are

located on your machine you need to become

competent in the correct operation of these

components prior to spraying operation.

It is also important to become familiar with

common spraying methods and common

spraying terms prior to using this sprayer for

the first time.

Chassis

The chassis is an all steel construction. The

chassis is shot blasted, primed and then

protected by the Goldacres paint process for

excellent chemical resistance and durability.

Tank

All tanks are constructed from UV resistant

polyethylene. Polyethylene tanks have a very

high chemical resistance.

Due to the rotomoulding process, there can be

a variance in the overall dimensions of the tank

which in turn results in variations to the tank

capacity. For this reason, calibration markings

should be used as a guide only.

Filtration

Filtration is a critical part of the sprayer’s

performance.

A suction filter between the tank and the pump

handles filtration. It is important that the filter is

cleaned out regularly.

Pump

The pump is critical to any sprayer

performance. Correct operation and

maintenance of the pump will ensure the

sprayer is able to perform to its capabilities.

Always flush pump with clean water after every

use. Prolonged chemical contact can severely

damage valves, diaphragms and seals.

Do not leave water in pump if sprayer is to

be left in a cold environment. The water may

freeze and cause damage to pump. Empty

pump of all water and cover the pump to

ensure this situation does not arise. If this has

not been done, and there is a possibility there

may be frozen water in the pump, wait until

any ice has thawed before using the pump.

Machine limitations

All Goldacres equipment is subject to

operating limitations, it is the operator’s

responsibility to ensure that this equipment

is being operated within these limitations and

appropriately to the operating conditions at

hand.

Paint Colours

Steel work: G13 Dark Green

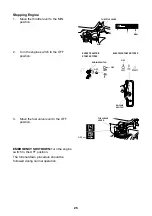

Identification

When ordering parts or requesting service

information for your sprayer, it is important to

quote the serial number and the purchase date

of your machine. This will assist with receiving

the most accurate information. The location of

the stamped ID plate is shown below.