17

Circuit Protector

If the motor has been optioned with electric

start, then it will also have a circuit protector

fitted which protects the battery charging

circuit. A short circuit, or a battery connected

with reverse polarity, will trip the circuit

protector.

The green indicator inside the circuit protector

will pop out to show that the circuit protector

has switched off. If this occurs, determine the

cause of the problem, and correct it before

resetting the circuit protector.

Push the circuit protector button to reset.

Starting Engine

1. Move the fuel valve lever to the ON

position.

2. If the engine is cold, move the choke

lever to the CLOSED position.

If restarting a warm engine, leave the choke

lever in the OPEN position.

3. Move the throttle lever approximately 1/3

of the way from the MIN. position.

4.

Turn the engine switch to the ON

position.

ENGLISH

3

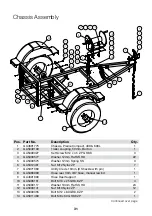

COMPONENT & CONTROL LOCATIONS

FEATURES

OIL ALERT

®

SYSTEM (applicable types)

‘‘Oil Alert is a registered trademark in the United States’’

The Oil Alert system is designed to prevent engine damage caused

by an insufficient amount of oil in the crankcase. Before the oil

level in the crankcase can fall below a safe limit, the Oil Alert

system will automatically stop the engine (the engine switch will

remain in the ON position).

If the engine stops and will not restart, check the engine oil level

(see page 8) before troubleshooting in other areas.

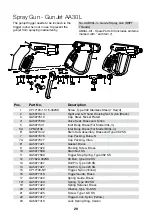

CIRCUIT PROTECTOR (applicable types)

The circuit protector protects the

battery charging circuit. A short

circuit, or a battery connected with

reverse polarity, will trip the circuit

protector.

The green indicator inside the circuit

protector will pop out to show that the

circuit protector has switched off. If

this occurs, determine the cause of

the problem, and correct it before

resetting the circuit protector.

Push the circuit protector button to

reset.

FUEL FILLER CAP

FUEL TANK

OIL DRAIN PLUG

ELECTRIC STARTER

(applicable type)

OIL FILLER CAP/DIPSTICK

RECOIL STARTER

AIR CLEANER

MUFFLER

SPARK PLUG

STARTER GRIP

ENGINE CONTROL TYPES

FUEL VALVE LEVER

CHOKE LEVER

EXCEPT ELECTRIC STARTER

TYPES

ENGINE SWITCH

THROTTLE LEVER

CHOKE LEVER

(air cleaner low profile type)

ELECTRIC STARTER TYPES

ENGINE

SWITCH

CIRCUIT

PROTECTOR

CIRCUIT

PROTECTOR

ON

OFF

37Z4V6100.fm 3 ページ 2018年10月4日 木曜日 午後1時54分

4

ENGLISH

BEFORE OPERATION CHECKS

IS YOUR ENGINE READY TO GO?

For your safety, to ensure compliance with environmental

regulations, and to maximize the service life of your equipment, it is

very important to take a few moments before you operate the

engine to check its condition. Be sure to take care of any problem

you find, or have your servicing dealer correct it, before you

operate the engine.

Before beginning your pre-operation checks, be sure the engine is

level and the engine switch is in the OFF position.

Always check the following items before you start the engine:

Check the General Condition of the Engine

1. Look around and underneath the engine for signs of oil or

gasoline leaks.

2. Remove any excessive dirt or debris, especially around the

muffler and recoil starter.

3. Look for signs of damage.

4. Check that all shields and covers are in place, and all nuts,

bolts, and screws are tightened.

Check the Engine

1. Check the fuel level (see page 8). Starting with a full tank will

help to eliminate or reduce operating interruptions for refueling.

2. Check the engine oil level (see page 8). Running the engine with

a low oil level can cause engine damage.

The Oil Alert system (applicable types) will automatically stop

the engine before the oil level falls below safe limits. However,

to avoid the inconvenience of an unexpected shutdown, always

check the engine oil level before startup.

3. Check the reduction case oil level on applicable types (see page

9). Oil is essential to reduction case operation and long life.

4. Check the air filter element (see page 10). A dirty air filter

element will restrict air flow to the carburetor, reducing engine

performance.

5. Check the equipment powered by this engine.

Review the instructions provided with the equipment powered

by this engine for any precautions and procedures that should

be followed before engine startup.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION

section on page 2 and the

BEFORE

OPERATION CHECKS

on page 4.

Carbon Monoxide Hazards

For your safety, do not operate the engine in an enclosed area such

as a garage. Your engine’s exhaust contains poisonous carbon

monoxide gas that can collect rapidly in an enclosed area and

cause illness or death.

Review the instructions provided with the equipment powered by

this engine for any safety precautions that should be observed with

engine startup, shutdown, or operation.

Do not operate the engine on slopes greater than 20° (36%).

STARTING THE ENGINE

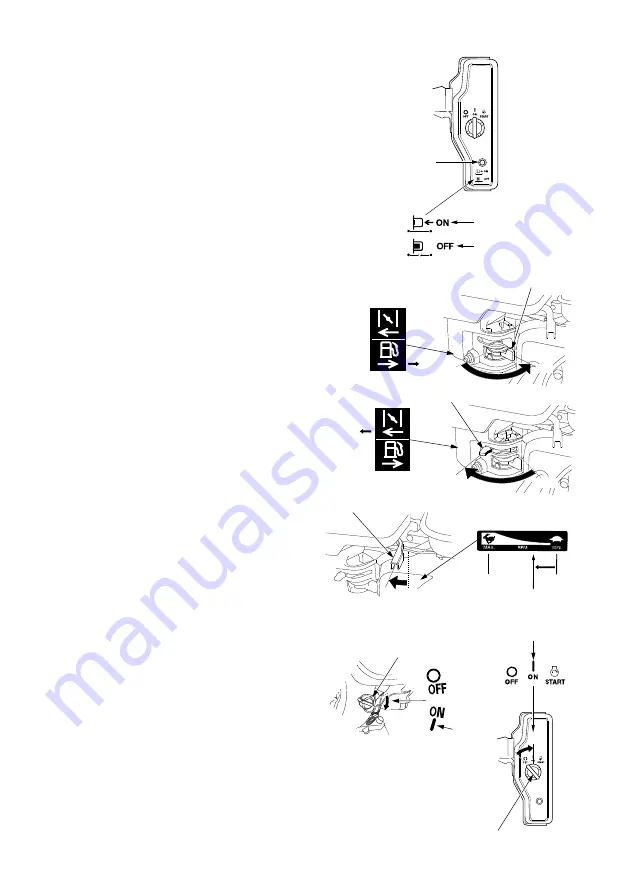

1. Move the fuel valve lever to the ON position.

2. To start a cold engine, move the choke lever to the CLOSED

position.

To restart a warm engine, leave the choke lever in the OPEN

position.

Some engine applications use a remote-mounted choke control

rather than the engine-mounted choke lever shown here. Refer

to the instructions provided by the equipment manufacturer.

Failure to properly maintain this engine, or failing to

correct a problem before operation, could result in a

significant malfunction.

Some malfunctions can seriously hurt or kill you.

Always perform a pre-operation inspection before

each operation and correct any problems.

Exhaust contains poisonous carbon monoxide gas

that can build up to dangerous levels in closed areas.

Breathing carbon monoxide can cause

unconsciousness or death.

Never run the engine in a closed, or even partly closed

area.

FUEL VALVE LEVER

ON

OFF

ON

CHOKE LEVER

CLOSED

CLOSED

OPEN

37Z4V6100.fm 4 ページ 2018年10月4日 木曜日 午後1時54分

4

ENGLISH

BEFORE OPERATION CHECKS

IS YOUR ENGINE READY TO GO?

For your safety, to ensure compliance with environmental

regulations, and to maximize the service life of your equipment, it is

very important to take a few moments before you operate the

engine to check its condition. Be sure to take care of any problem

you find, or have your servicing dealer correct it, before you

operate the engine.

Before beginning your pre-operation checks, be sure the engine is

level and the engine switch is in the OFF position.

Always check the following items before you start the engine:

Check the General Condition of the Engine

1. Look around and underneath the engine for signs of oil or

gasoline leaks.

2. Remove any excessive dirt or debris, especially around the

muffler and recoil starter.

3. Look for signs of damage.

4. Check that all shields and covers are in place, and all nuts,

bolts, and screws are tightened.

Check the Engine

1. Check the fuel level (see page 8). Starting with a full tank will

help to eliminate or reduce operating interruptions for refueling.

2. Check the engine oil level (see page 8). Running the engine with

a low oil level can cause engine damage.

The Oil Alert system (applicable types) will automatically stop

the engine before the oil level falls below safe limits. However,

to avoid the inconvenience of an unexpected shutdown, always

check the engine oil level before startup.

3. Check the reduction case oil level on applicable types (see page

9). Oil is essential to reduction case operation and long life.

4. Check the air filter element (see page 10). A dirty air filter

element will restrict air flow to the carburetor, reducing engine

performance.

5. Check the equipment powered by this engine.

Review the instructions provided with the equipment powered

by this engine for any precautions and procedures that should

be followed before engine startup.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION

section on page 2 and the

BEFORE

OPERATION CHECKS

on page 4.

Carbon Monoxide Hazards

For your safety, do not operate the engine in an enclosed area such

as a garage. Your engine’s exhaust contains poisonous carbon

monoxide gas that can collect rapidly in an enclosed area and

cause illness or death.

Review the instructions provided with the equipment powered by

this engine for any safety precautions that should be observed with

engine startup, shutdown, or operation.

Do not operate the engine on slopes greater than 20° (36%).

STARTING THE ENGINE

1. Move the fuel valve lever to the ON position.

2. To start a cold engine, move the choke lever to the CLOSED

position.

To restart a warm engine, leave the choke lever in the OPEN

position.

Some engine applications use a remote-mounted choke control

rather than the engine-mounted choke lever shown here. Refer

to the instructions provided by the equipment manufacturer.

Failure to properly maintain this engine, or failing to

correct a problem before operation, could result in a

significant malfunction.

Some malfunctions can seriously hurt or kill you.

Always perform a pre-operation inspection before

each operation and correct any problems.

Exhaust contains poisonous carbon monoxide gas

that can build up to dangerous levels in closed areas.

Breathing carbon monoxide can cause

unconsciousness or death.

Never run the engine in a closed, or even partly closed

area.

FUEL VALVE LEVER

ON

OFF

ON

CHOKE LEVER

CLOSED

CLOSED

OPEN

37Z4V6100.fm 4 ページ 2018年10月4日 木曜日 午後1時54分

ENGLISH

5

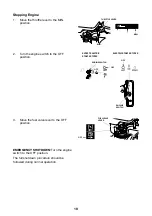

3. Move the throttle lever away from the MIN. position, about 1/3

of the way toward the MAX. position.

Some engine applications use a remote-mounted throttle control

rather than the engine-mounted throttle lever shown here. Refer

to the instructions provided by the equipment manufacturer.

4. Turn the engine switch to the ON position.

5. Operate the starter.

RECOIL STARTER:

Pull the starter grip lightly until you feel resistance, then pull

briskly in the direction of the arrow as shown below. Return the

starter grip gently.

Do not allow the starter grip to snap back against the engine.

Return it gently to prevent damage to the starter.

ELECTRIC STARTER (applicable types):

Turn the key to the START position,

and hold it there until the engine

starts.

If the engine fails to start within 5

seconds, release the key, and wait at

least 10 seconds before operating the

starter again.

Using the electric starter for more

than 5 seconds at a time will overheat

the starter motor and can damage it.

This type of overheating is not

covered under warranty.

When the engine starts, release the

key, allowing it to return to the ON

position.

6. If the choke lever was moved to the CLOSED position to start

the engine, gradually move it to the OPEN position as the

engine warms up.

THROTTLE LEVER

MAX.

MIN.

1/3 POSITION

MIN.

EXCEPT ELECTRIC

STARTER TYPES

ELECTRIC STARTER TYPES

ON

ENGINE SWITCH

ON

ENGINE SWITCH

ON

ON

STARTER GRIP

Direction to pull

START

START

ENGINE SWITCH

(applicable types)

OPEN

CHOKE LEVER

CLOSED

OPEN

37Z4V6100.fm ページ 2018年10月4日 木曜日 午後1時54分

ENGLISH

5

3. Move the throttle lever away from the MIN. position, about 1/3

of the way toward the MAX. position.

Some engine applications use a remote-mounted throttle control

rather than the engine-mounted throttle lever shown here. Refer

to the instructions provided by the equipment manufacturer.

4. Turn the engine switch to the ON position.

5. Operate the starter.

RECOIL STARTER:

Pull the starter grip lightly until you feel resistance, then pull

briskly in the direction of the arrow as shown below. Return the

starter grip gently.

Do not allow the starter grip to snap back against the engine.

Return it gently to prevent damage to the starter.

ELECTRIC STARTER (applicable types):

Turn the key to the START position,

and hold it there until the engine

starts.

If the engine fails to start within 5

seconds, release the key, and wait at

least 10 seconds before operating the

starter again.

Using the electric starter for more

than 5 seconds at a time will overheat

the starter motor and can damage it.

This type of overheating is not

covered under warranty.

When the engine starts, release the

key, allowing it to return to the ON

position.

6. If the choke lever was moved to the CLOSED position to start

the engine, gradually move it to the OPEN position as the

engine warms up.

THROTTLE LEVER

MAX.

MIN.

1/3 POSITION

MIN.

EXCEPT ELECTRIC

STARTER TYPES

ELECTRIC STARTER TYPES

ON

ENGINE SWITCH

ON

ENGINE SWITCH

ON

ON

STARTER GRIP

Direction to pull

START

START

ENGINE SWITCH

(applicable types)

OPEN

CHOKE LEVER

CLOSED

OPEN

37Z4V6100.fm ページ 2018年10月4日 木曜日 午後1時54分