11

General Information &

Specifications

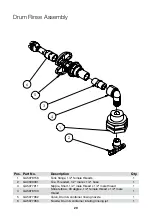

The SuperFlow Mobile Hopper is an alternative

method of transferring chemical into the

main spray tank. The chemical can either be

in liquid form or granular form and once in

the hopper the chemical can then be easily

transferred into the main spray tank. The

hopper facilitates drum rinsing with fresh water

and the hopper itself can be rinsed and all

rinsate then transferred into the tank.

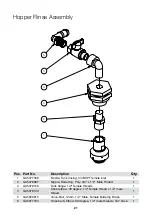

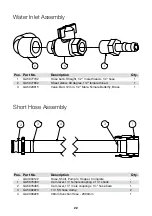

The hopper transfers the chemical via venturi

effect. Water from an external supply is

pumped under the bottom of the hopper

where it passes through a venturi fitting under

the hopper. This causes a suction effect and

when the bottom of the hopper is open (via

the hopper tank ball valve) the tank contents

are drawn into the flow from the pump passing

under the hopper and then transferred into

the main spray tank. This eliminates chemical

attack resulting from high concentrations

of chemical coming into contact with spray

components.

NOTE:

The level indicator should be used as a

guide only.

NOTE:

Never let the hopper run empty or suck

air, this may cause foaming in the main tank.

Know Your Sprayer

Getting to know your sprayer prior to operation

is crucial in the safe and efficient operation

of this equipment. Take the time to familiarise

yourself with all the standard and optional

components fitted to your sprayer, not only do

you need to know where key components are

located on your machine you need to become

competent in the correct operation of these

components prior to spraying operation.

It is also important to become familiar with

common spraying methods and common

spraying terms prior to using this sprayer for

the first time

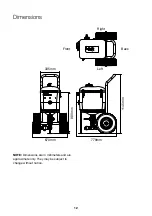

Chassis

The chassis is an all steel construction. The

chassis is shot blasted, primed and then

protected by the Goldacres paint process for

excellent chemical resistance and durability.

Tank

All tanks are constructed from UV resistant

polyethylene. Polyethylene tanks have a very

high chemical resistance.

Due to the rotomoulding process, there can be

a variance in the overall dimensions of the tank

which in turn results in variations to the tank

capacity. For this reason, calibration markings

should be used as a guide only.

Paint Colours

Steel work: G13 Dark Green

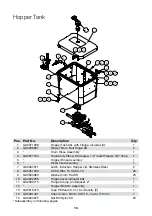

Hopper Tank

Always flush hopper with clean water after

every use. Prolonged chemical contact can

severely damage valves and seals.

Do not leave water in hopper if sprayer is to

be left in a cold environment. The water may

freeze and cause damage to the system when

connected. Empty hopper of all water and

cover the pump to ensure this situation does

not arise. If this has not been done, and there

is a possibility there may be frozen water in the

hopper, wait until any ice has thawed before

connecting to pump.

Machine limitations

All Goldacres equipment is subject to

operating limitations, it is the operator’s

responsibility to ensure that this equipment

is being operated within these limitations and

appropriately to the operating conditions at

hand.