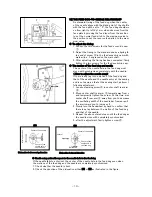

◆ Clearance between the needdle and the shuttle driver

The clearance between the needle and the needle guide

of the shuttle driver has already been adjusted to the ran

of 0 through 0.05 mm.

To adjust the clearance between the needle and the shut

-le driver:

1. Loosen two screws ⑮, and remove thrust collar ⑭ of

the feed rock driving shaft on the feed bracket.

2. Loosen two screws ⑰, and move thrust collar ⑯ of th

feed rock shaft.

3. Loosen two screws ⑱ in the shuttle driving shaft thrus

collar, screw ⑲ in the shuttle driving shaft front bushin

and small pendulum clamping screw ⑳.

4. Adjust the clearance by moving shuttle driving shaft fro

bushing

21

to the left and right.

5. After the adjustment has been completed, secure the

shuttle driving shaft thrust collar and the small pendulu

making sure there is no axial play of the shuttle driving

shaft.

6. Finally, secure the respective thrust collars, making su

there is no play in the feed driving shaft and the feed

rock shaft.

The standard for adjusting the clearance between the needle

and the blade point of the shuttle

Use a standard Schmetz 794-Nm 230 needle.

1. Adjust the clearance Ⅴ between the convex section o

needle

22

and shuttle driver

23

to 0.

2. Align the needle center with the blade point of the shu

ttle

24

and press the Ⅵ section of the needle against

the shuttle driver.

3. Adjust the clearance Ⅶ to a minimum, with the needle

pressed against the shuttle driver, making sure that the

needle does not contact the blade point of the shuttle.

・ By this adjustment the needle-to-shuttle blade point

clearance will be 0.25 ~0.35 mm.

⑯

⑰

⑭

⑮

⑳

21

⑲ ⑱

22

23

24

Ⅴ

Ⅵ

Ⅶ

- 9 -

Summary of Contents for CS-471

Page 12: ...memo 13 ...