6

MOUNT CROSSBEAMS

Note: The Square Tube Leg(s) referenced in this step is an

optional part purchased with the Tornado Boat Lift. If the Square

Tube Leg part was not ordered and included, you may skip to the

next step.

Note: Cross Beams will ship with leg pockets pre-assembled

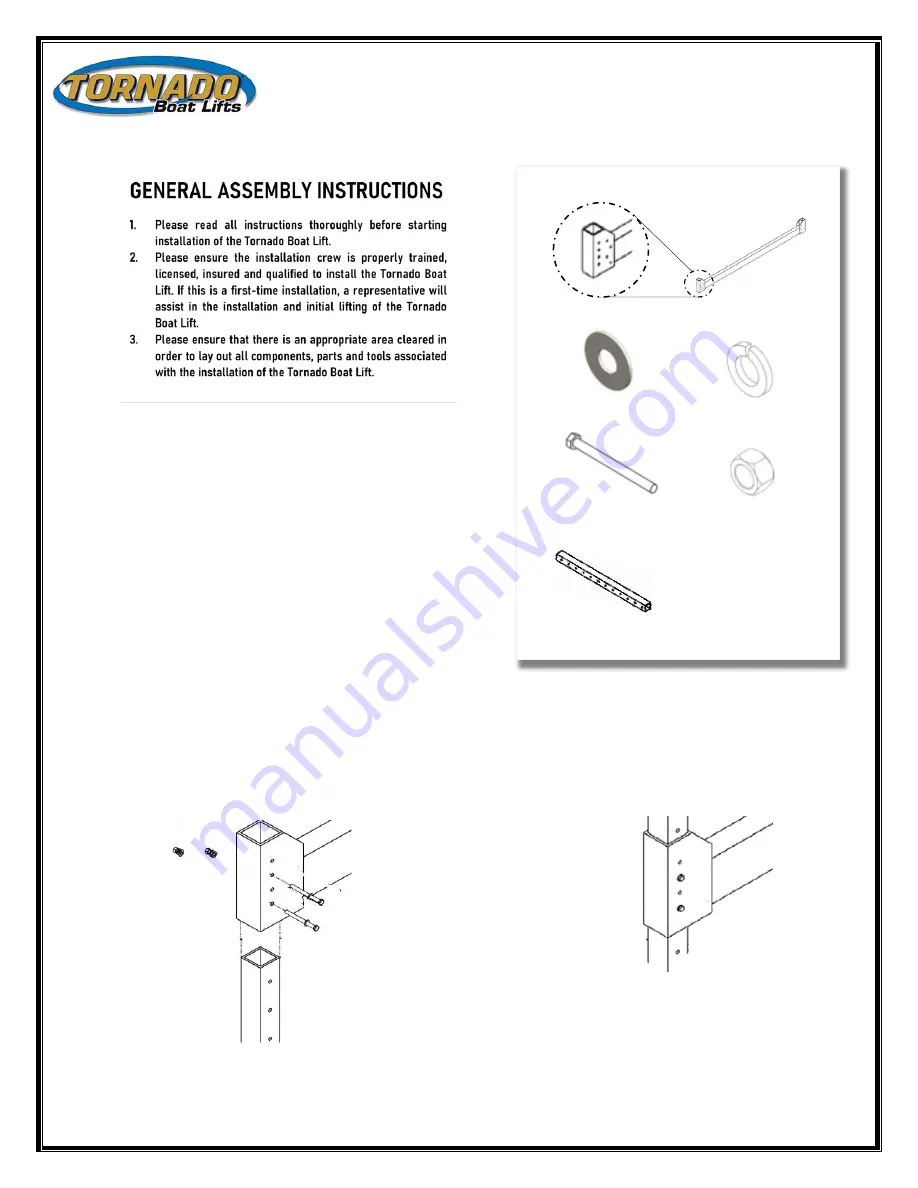

Note: Ensure Crossbeam and Leg Pocket is oriented in the

upward position as shown in Figure 1.

1.

Slide Crossbeam Leg Pocket over Square Tube Leg as

shown in Figure 1 and adjust to desired height.

2.

Attach one (1) 3/8” Flat Washer onto two (2) 3/8” x 4

-

1/2” Hex

Bolts and insert them into Leg Pocket, securing the

Crossbeam to the Square Tube Leg shown in Figure 1.

3.

Attach one (1) 3/8” Flat Washer, one (1) 3/8” Lock Washer,

and one (1) 3/8” Hex

Nut over the two (2) protruding ends of

the Hex Bolts and securely fasten with appropriate wrench

until secure as shown in Figure 2.

4.

Repeat these steps three (3) more times, once for the

opposite side of the Cross Beam, and twice for the second

Cross Beam.

PARTS REQUIRED TO MOUNT CROSSBEAM

Leg Pocket

3/8” Flat Washer (16)

3/8” x 4

-

1/2” Hex Bolt

(8)

Crossbeam (2)

3/8” Lock Washer (8)

3/8” Hex Nut (8)

Figure 1

Figure 2

Square Tube Leg (4)

Summary of Contents for Tornado 1-CYLINDER

Page 3: ...3 ...