8.

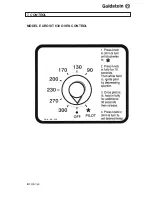

THERMOSTAT SETTING

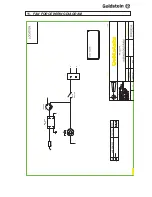

INSTALLATION

630 EUROSIT complies with current safety standards.

Nevertheless, its installation on appliances must be verified in accordance

with specific standards for each installation. In particular, it is necessary

to ensure that requirements relating to the class of flame failure device are

met. All the installation, setting and adjustment operations must be carried

out exclusively by qualified personnel on the basis of the specific characteristics

of the appliance. The valve is not for outdoor use.

MECHANICAL CONNECTIONS

General recommendations

Do not tamper with sealed parts. Do not slacken assembly screws. Do not remove

labels. Avoid blows (knocks, falls etc.). Only remove dust caps when installing.

Do not exceed recommended torques. Ensure that the gas flows in the direction

shown by the arrow on the valve body. Prevent foreign matter from getting into the

valve during installation. In particular, check the cleanliness of the inlet and outlet

pipes.Do not subject the valve to bending in excess of 35 Nm and to torque in

excess of 25 Nm.Use only the specified spanner grips when making the connections.

The valve has three pairs of retaining holes.

Main gas connection

The connection must be made using gas pipes with Rp 3/8 ISO 7 thread. Torque

25Nm. Alternatively, it is possible to use nut and olive connections for

12mm pipe

(code nos.0.958.025 and 0.957.007) (torque 15 Nm) The valve has two main gas

inlets (10 and 12) and two outlets (11 and 13). The outlets which are not used must

be sealed by screwing the special plug (code 0.972.061) in flush Torque 7 Nm.

Connection to pilot burner

4mm, 6mm and ¼” pipes can be used. Use appropriately sized nut and olive.

Tighten to 7Nm torque. After making the gas connections, check seals and ensure

appliance works properly.

IM037B1/p10