Sensor Calibration

Calibration Using Calibration Panel CP 40

Page 33 (44)

at

os

2-

3_r

ev02_

so

-40

0-

800

-v7

-5

-0_en_r

ev

-b

2012

-01

-03

The CP40 calibration objects consist of black points on a white back-

ground. The larger points in the middle inform the ATOS software

about the calibration panel type, e.g. calibration object CP40 for mea-

suring volume MV320.

Each point was measured photogrammetrically in the factory. Not only

the black points are used for calibration but the white spaces as well

(calibration of individual cameras). Therefore, always ensure that the

calibration panel is clean (see section 9.3.1).

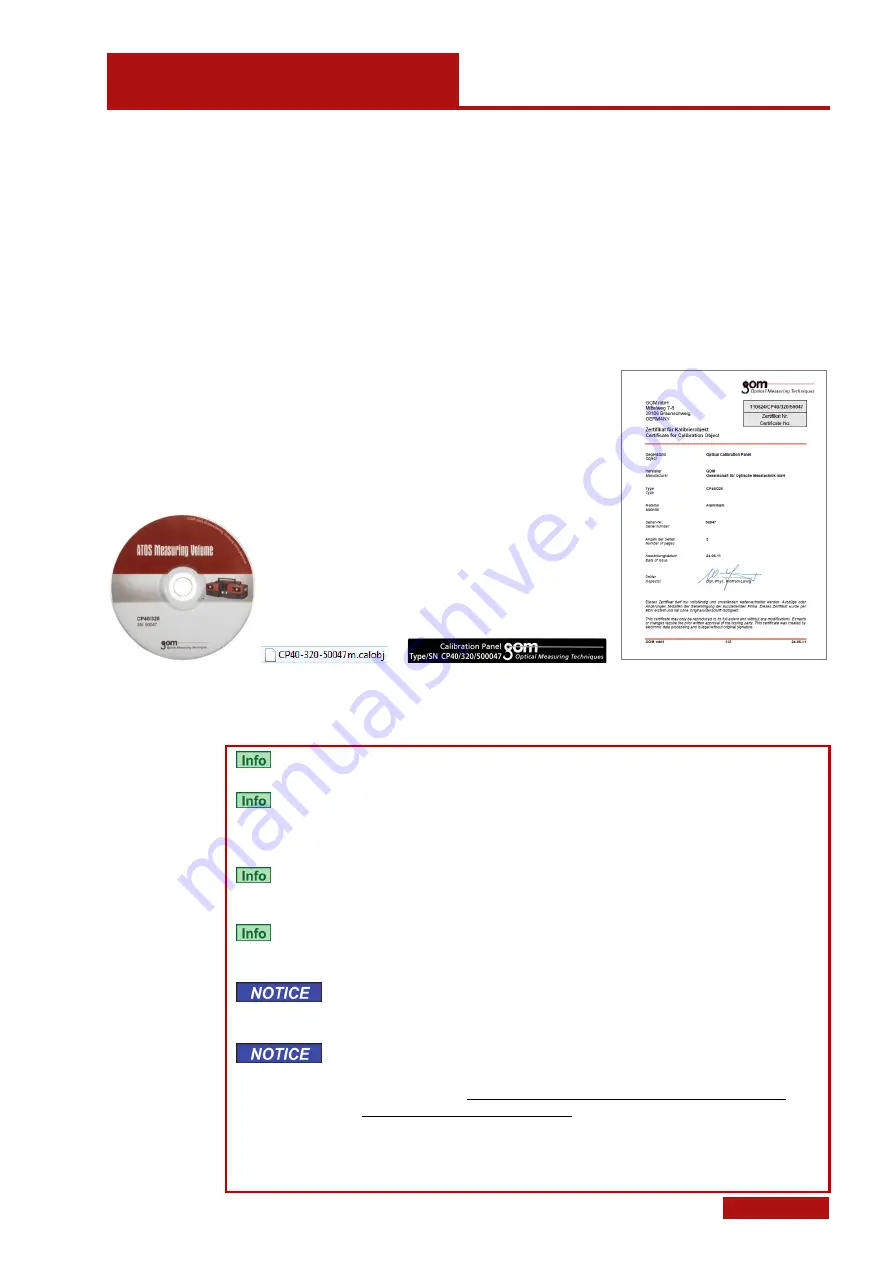

For each calibration panel there is a CD containing the calibration da-

ta (file extension

.calobj

) and the certificate.

A unique serial number provides for correct matching of calibration ob-

ject, certificate and calibration data.

Calibration CD with serial no. File name calibration data Serial no. of calibration panel

Certificate with serial no.

9.3.1

Handling Instructions for Calibration Panel CP40

The surface of the calibration panel is very sensitive. Therefore, nev-

er touch the surface directly with your hands.

Calibration panels for measuring volumes with camera position

400

and

800

remain in the case during the calibration process. Only the

case cover is removed. Please remove the case cover carefully to

prevent any damage to the surface of the panel.

Clean the surface of the panel using the enclosed microfiber cloth

from the standard tool box. Wipe the surface gently only. Never exert

any pressure.

Damaged points will not be used for calibration. Dirty white areas will

be ignored during calibration and the process uses the clean neigh-

boring areas.

Soiling and damages in the area of the larger calibration points in the

middle may cause that the ATOS software does not identify the pan-

el!

If you use multiple ATOS Triple Scan sensors, please check that the

serial number of your calibration object matches the calibration data

in the software. The software only checks the correct type of the

panel but not the serial number.

It is mandatory that the serial number of the calibration object is iden-

tical to the serial number of the calibration object in the ATOS soft-

ware!

Otherwise your measuring system may provide inaccurate

measuring data!