Sensor Calibration

Calibration Using Calibration Cross CC 30

Page 37 (44)

at

os

2-

3_r

ev02_

so

-40

0-

800

-v7

-5

-0_en_r

ev

-b

2012

-01

-03

9.4

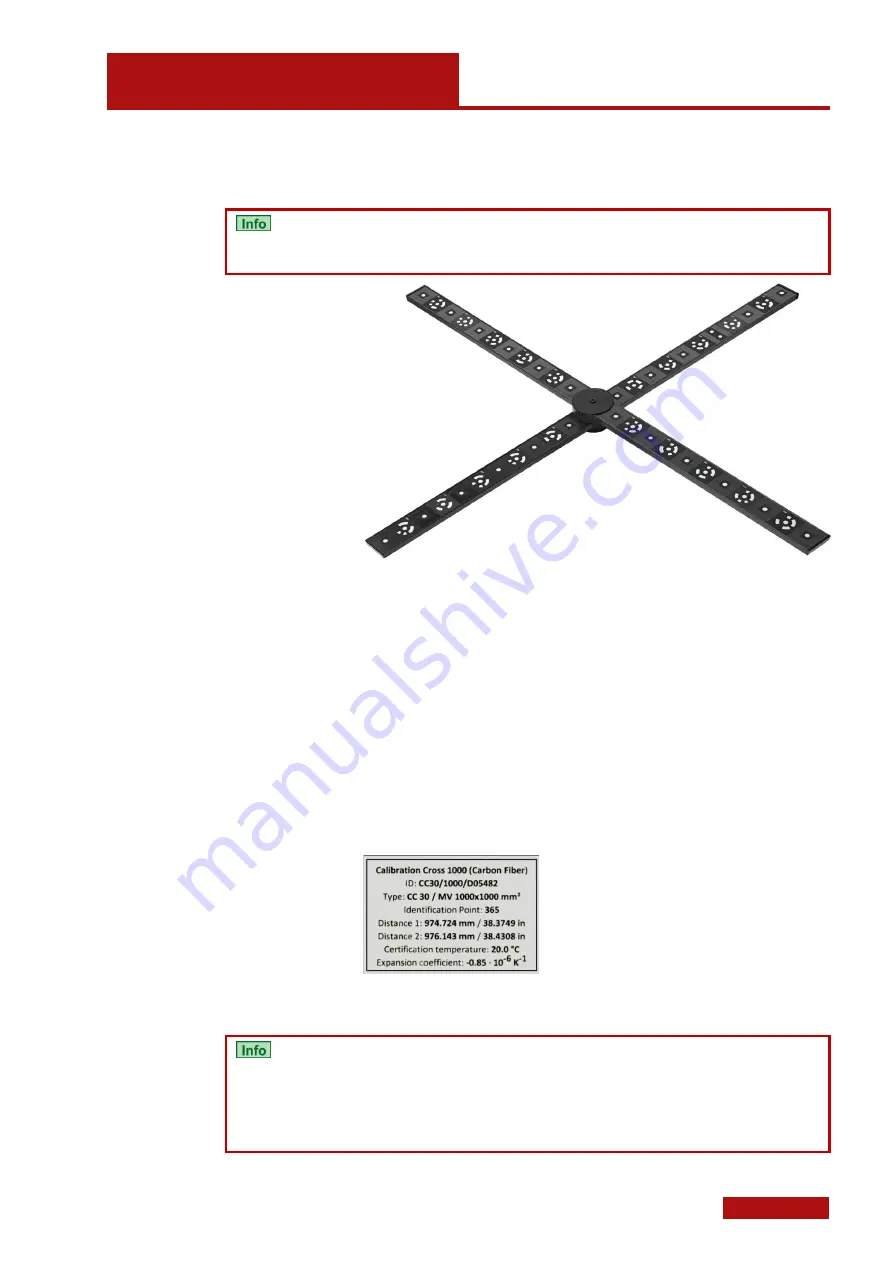

Calibration Using Calibration Cross CC 30

This section describes the calibration process using a calibration

cross.

Due to the size of the cross you can only calibrate the sensor in a ho-

rizontal position. Therefore it is useful to mount the calibration cross

on a stand.

Calibration cross CC 30

During calibration, the sensor configuration is determined. This means

that the camera positions and the orientation of the cameras to each

other are defined, and the image characteristics of the cameras are

determined. Based on these settings, the software calculates from the

points of the calibration object in the 2D camera image their 3D coor-

dinates. The calculated 3D coordinates are then calculated back again

into the 2D camera images. For the position of the reference points,

this results in the so-called reference point deviation (intersection er-

ror).

The calibration cross also contains the information of two scale bars

(one on each cross axis). The scale bar information is a specified dis-

tance between defined points.

For each calibration cross there is the calibration certificate with the

calibration data. You can also see the calibration data on the rear side

of the cross.

Calibration date example on the rear side of a CC 30 calibration cross

9.4.1

Handling Instructions for Calibration Cross CC 30

The point surface of the calibration cross is very sensitive. Therefore,

never touch the surface directly with your hands.

Clean the surface of the cross using the enclosed microfiber cloth

from the standard tool box. Wipe the surface gently only. Never exert

any pressure.

The calibration cross must be totally unfolded.