D122.A

4 Manual

Page 19

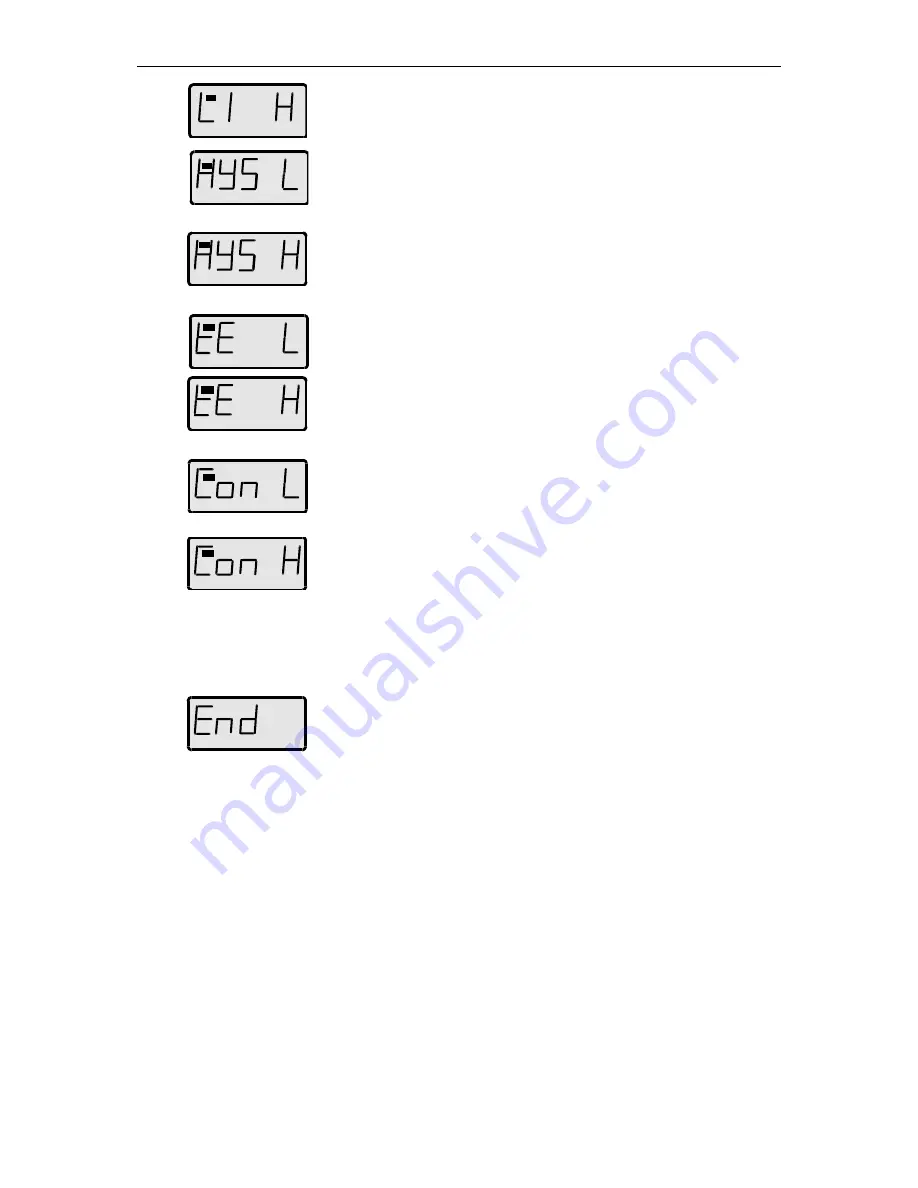

SET

Press the

enter

-button and enter

[2000] (20°C)

for the

upper

limit

.

Confirm by hitting the e

nter-

button.

SET

SET

To select the

hysteresis of the lower limit

press the e

nter-

button.

Now enter

[0050] (0,5°C)

using the arrow-buttons and confirm

with the e

nter-

button.

SET

To select the

hysteresis of the upper limit

press the e

nter-

button.

Now enter

[0050] (0,5°C)

using the arrow-buttons and confirm

with the e

nter-

button.

SET

SET

Now press enter-button to activate the time delay.

Enter [0015] (15 seconds) for both limits.

Confirm by hitting the

enter-

button.

SET

Now define the circuit-opening connection first for the low alarm

limit.

Choose the circuit-opening connection [nc---] (normal closed)

using the

up

-button and confirm by pressing

enter

-button.

SET

Define the circuit-opening connection for the upper alarm monitor

by the same procedure.

Confirm by hitting the

enter-

button and quit the limit menu.

We pass simply the following menu items (manipulate code

words and calibrate) using the

right

-button.

Finally quit the scale menu hitting the

enter-

button.

The indicator is back in normal state. The changes are immedi-

ately active and will be stored after turn off (disconnecting the

indicator).