SERVICING

25

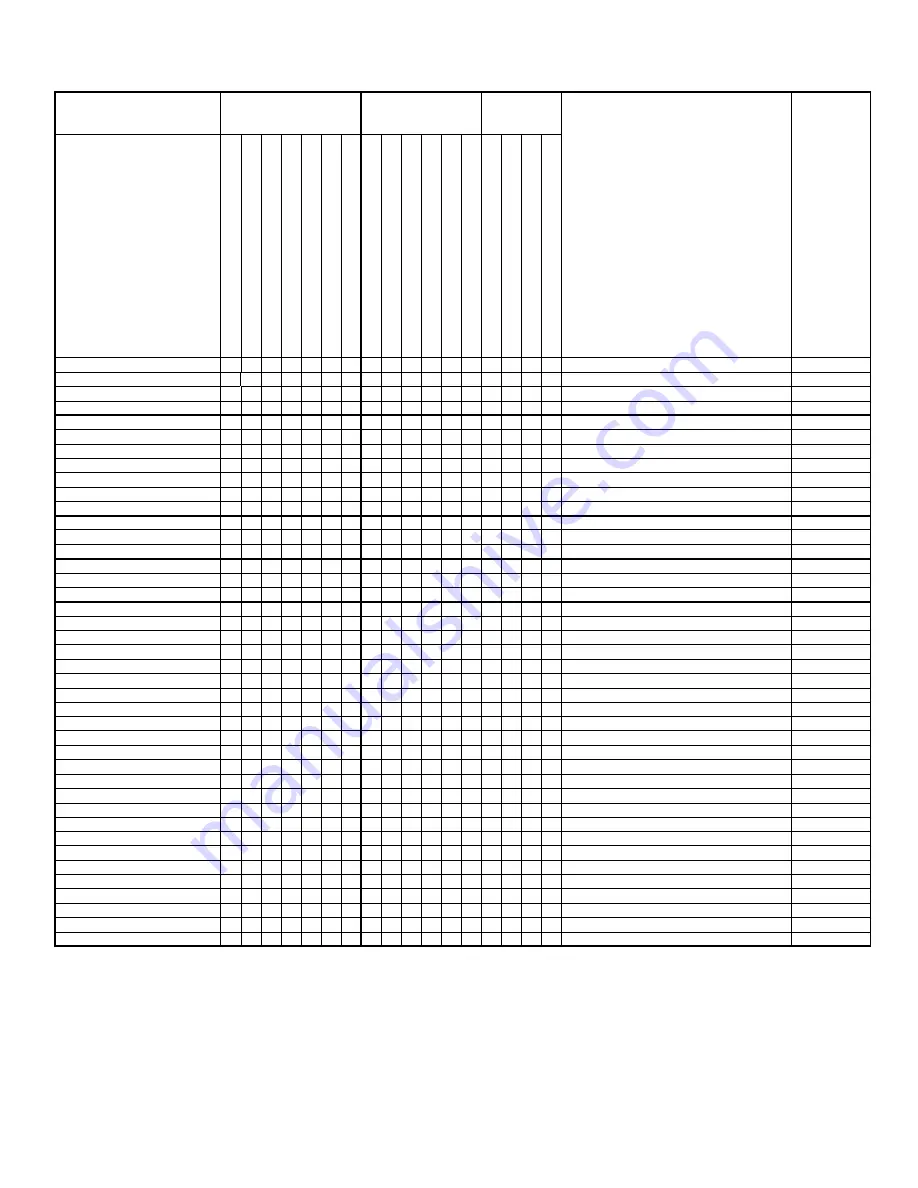

COOLING - SERVICE ANALYSIS GUIDE

X = applies to 3 phase units only

Complaint

System

Operating

Pressures

POSSIBLE CAUSE

DOTS IN ANALYSIS

GUIDE INDICATE

"POSSIBLE CAUSE"

SYMPTOM

S

y

s

te

m

w

ill

n

o

t s

ta

rt

C

o

m

p

re

s

s

o

r w

ill

n

o

t

st

a

rt

- f

a

n

ru

n

s

Com

p

.

a

nd Co

nd

. F

an wi

ll n

o

t

s

tar

t

E

v

a

p

o

ra

to

r fa

n

w

ill

n

o

t

sta

rt

C

o

nd

en

se

r f

a

n wi

ll no

t st

a

rt

Com

p

re

s

s

o

r

ru

ns

-

goe

s

o

ff

on ov

e

rl

o

ad

C

o

m

p

re

ssor

cycl

e

s

o

n

o

v

er

lo

a

d

S

y

st

em

r

u

ns

c

o

nt

in

uo

us

ly

-

l

it

tl

e

c

o

o

lin

g

T

o

o

co

o

l

an

d

th

en

t

o

o

w

a

rm

N

o

t co

o

l

en

ou

g

h

on

w

a

rm

d

a

y

s

C

e

rt

ai

n

a

rea

s t

o

o

co

ol

,

ot

he

rs

t

o

o

w

a

rm

C

o

m

p

re

ssor

wo

n'

t sh

ift

to

h

ig

h

sta

g

e

coo

lin

g

C

o

m

p

re

s

s

o

r i

s

n

o

is

y

L

o

w suct

io

n pr

e

ssu

re

L

o

w he

ad

p

ressu

re

H

igh

su

cti

o

n

pr

e

ssur

e

Hi

g

h

he

ad pr

es

s

u

re

Test Method

Remedy

S

ee S

e

rv

ice

Pr

oce

dure

R

e

f.

Power Failure

•

Test Voltage

S-1

Blown Fuse

•

X

• •

X

Inspect Fuse Size & Type

S-1

Loose Connection

•

• • • •

Inspect Connection - Tighten

S-2, S-3

Shorted or Broken Wires

• • • • • •

Test Circuits With Ohmmeter

S-2,S-3

Open Overload

•

• • •

Test Continuity of Overload

S-16A, S-17A

Faulty Thermostat

•

•

Test continuity of Thermostat & Wiring

S-3

Faulty Transformer

•

•

Check control circuit with voltmeter

S-4

Shorted or Open Capacitor

•

• • •

X

Test Capacitor

S-15

Shorted or Grounded Compressor

•

•

Test Motor Windings

S-17B

Unloader Solenoid

•

•

•

Test unloader operation

S-17C

Compressor Stuck

• •

•

Use Test Cord

S-17D

Faulty Compressor Contactor

•

•

• •

Test continuity of Coil & Contacts

S-7, S-8

Faulty Fan Relay

•

Test continuity of Coil And Contacts

S-7

Open Control Circuit

• • •

Test Control Circuit with Voltmeter

S-4

Low Voltage

•

• •

Test Voltage

S-1

Faulty Evap. Fan Motor

•

•

Repair or Replace

S-16A

Shorted or Grounded Fan Motor

•

•

Test Motor Windings

S-16A

Improper Cooling Anticipator

•

•

Check resistance of Anticipator

S-3B

Shortage of Refrigerant

• •

• •

Test For Leaks, Add Refrigerant

S-101, 103

Restricted Liquid Line

• •

• •

Remove Restriction, Replace Restricted Part

S-112

Dirty Air Filter

•

• •

•

Inspect Filter-Clean or Replace

Dirty Indoor Coil

•

• •

•

Inspect Coil - Clean

Not enough air across Indoor Coil

•

• •

•

Check Blower Speed, Duct Static Press, Filter

S-200

Too much air across Indoor Coil

•

Reduce Blower Speed

S-200

Overcharge of Refrigerant

• •

•

• •

Recover Part of Charge

S-113

Dirty Outdoor Coil

• •

•

•

Inspect Coil - Clean

Noncondensibles

•

•

•

Recover Charge, Evacuate, Recharge

S-114

Recirculation of Condensing Air

•

•

•

Remove Obstruction to Air Flow

Infiltration of Outdoor Air

•

• •

Check Windows, Doors, Vent Fans, Etc.

Improperly Located Thermostat

•

•

Relocate Thermostat

Air Flow Unbalanced

•

•

Readjust Air Volume Dampers

System Undersized

•

•

Refigure Cooling Load

Broken Internal Parts

•

Replace Compressor

S-115

Inefficient Compressor

•

• •

Test Compressor Efficiency

S-104

Unbalanced Power, 3PH

•

• •

Test Voltage

S-1

Wrong Type Expansion Valve

• • •

•

• •

Replace Valve

S-110

Expansion Device Restricted

• • •

•

• •

Remove restriction or replace expansion device

S-110

Expansion Valve Bulb Loose

•

Tighten Bulb Bracket

S-105

Inoperative Expansion Valve

•

•

•

Check Valve Operation

S-110

Loose Hold-down Bolts

•

Tighten Bolts

Flowrator Not Seating Properly

•

• •

Check Flowrator & Seat or Replace Flowrator

S-111

No Cooling

Unsatisfactory Cooling

![Preview for 11 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-11.webp)

![Preview for 12 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-12.webp)

![Preview for 13 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-13.webp)

![Preview for 14 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-14.webp)

![Preview for 15 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-15.webp)

![Preview for 16 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-16.webp)

![Preview for 17 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-17.webp)

![Preview for 18 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-18.webp)

![Preview for 19 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-19.webp)

![Preview for 20 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-20.webp)

![Preview for 21 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-21.webp)

![Preview for 22 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-22.webp)

![Preview for 23 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-23.webp)

![Preview for 24 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-24.webp)

![Preview for 25 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-25.webp)

![Preview for 26 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-26.webp)

![Preview for 27 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-27.webp)

![Preview for 28 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-28.webp)

![Preview for 29 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-29.webp)

![Preview for 30 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-30.webp)

![Preview for 31 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-31.webp)

![Preview for 32 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-32.webp)

![Preview for 33 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-33.webp)

![Preview for 34 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-34.webp)

![Preview for 35 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-35.webp)

![Preview for 36 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-36.webp)

![Preview for 37 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-37.webp)

![Preview for 38 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-38.webp)

![Preview for 39 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-39.webp)

![Preview for 40 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-40.webp)