SERVICING

31

S-15 CHECKING CAPACITOR

CAPACITOR, RUN

A run capacitor is wired across the auxiliary and main wind-

ings of a single phase permanent split capacitor motor. The

capacitors primary function is to reduce the line current while

greatly improving the torque characteristics of a motor. This is

accomplished by using the 90° phase relationship between

the capacitor current and voltage in conjunction with the motor

windings so that the motor will give two phase operation when

connected to a single phase circuit. The capacitor also re-

duces the line current to the motor by improving the power

factor.

CAPACITOR, START

SCROLL COMPRESSOR MODELS

Hard start components are not required on Scroll compressor

equipped units due to a non-replaceable check valve located in

the discharge line of the compressor. However hard start kits

are available and may improve low voltage starting characteris-

tics.

This check valve closes off high side pressure to the compres-

sor after shut down allowing equalization through the scroll

flanks. Equalization requires only about one or two seconds

during which time the compressor may turn backwards.

Your unit comes with a 180-second anti-short cycle to prevent

the compressor from starting and running backwards.

MODELS EQUIPPED WITH A HARD START DEVICE

A start capacitor is wired in parallel with the run capacitor to

increase the starting torque. The start capacitor is of the elec-

trolytic type, rather than metallized polypropylene as used in

the run capacitor.

A switching device must be wired in series with the capacitor

to remove it from the electrical circuit after the compressor

starts to run. Not removing the start capacitor will overheat the

capacitor and burn out the compressor windings.

These capacitors have a 15,000 ohm, 2 watt resistor wired

across its terminals. The object of the resistor is to discharge

the capacitor under certain operating conditions, rather than

having it discharge across the closing of the contacts within

the switching device such as the Start Relay, and to reduce

the chance of shock to the servicer. See the Servicing Section

for specific information concerning capacitors.

RELAY, START

A potential or voltage type relay is used to take the start ca-

pacitor out of the circuit once the motor comes up to speed.

This type of relay is position sensitive. The normally closed

contacts are wired in series with the start capacitor and the

relay holding coil is wired parallel with the start winding. As

the motor starts and comes up to speed, the increase in volt-

age across the start winding will energize the start relay hold-

ing coil and open the contacts to the start capacitor.

Two quick ways to test a capacitor are a resistance and a

capacitance check.

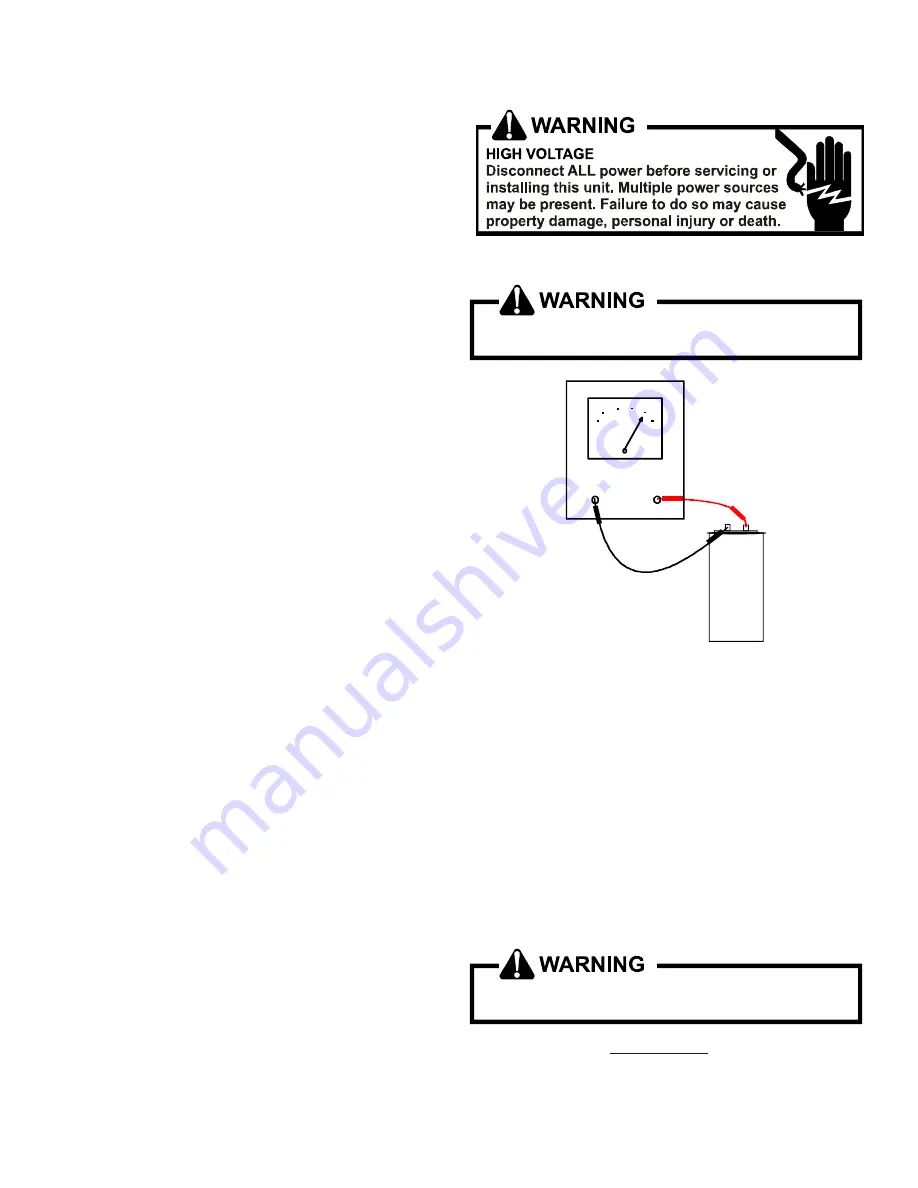

S-15A Resistance Check

1. Discharge capacitor and remove wire leads.

Discharge capacitor through a 20 to 30 OHM resistor

before handling.

Ca

p

aci

to

r

Volt / Ohm

Meter

TESTING CAPACITOR RESISTANCE

2. Set an ohmmeter on its highest ohm scale and connect

the leads to the capacitor -

A. Good Condition - indicator swings to zero and slowly

returns to infinity. (Start capacitor with bleed resistor will

not return to infinity. It will still read the resistance of the

resistor).

B. Shorted - indicator swings to zero and stops there -

replace.

C. Open - no reading - replace. (Start capacitor would read

resistor resistance).

S-15B Capacitance Check

Using a hookup as shown below, take the current and voltage

readings and use them in the formula:

Discharge capacitor through a 20 to 30 OHM resistor

before handling.

Capacitance (MFD) = 2650 X Current

Voltage

![Preview for 17 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-17.webp)

![Preview for 18 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-18.webp)

![Preview for 19 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-19.webp)

![Preview for 20 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-20.webp)

![Preview for 21 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-21.webp)

![Preview for 22 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-22.webp)

![Preview for 23 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-23.webp)

![Preview for 24 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-24.webp)

![Preview for 25 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-25.webp)

![Preview for 26 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-26.webp)

![Preview for 27 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-27.webp)

![Preview for 28 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-28.webp)

![Preview for 29 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-29.webp)

![Preview for 30 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-30.webp)

![Preview for 31 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-31.webp)

![Preview for 32 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-32.webp)

![Preview for 33 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-33.webp)

![Preview for 34 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-34.webp)

![Preview for 35 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-35.webp)

![Preview for 36 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-36.webp)

![Preview for 37 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-37.webp)

![Preview for 38 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-38.webp)

![Preview for 39 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-39.webp)

![Preview for 40 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-40.webp)

![Preview for 41 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-41.webp)

![Preview for 42 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-42.webp)

![Preview for 43 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-43.webp)

![Preview for 44 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-44.webp)

![Preview for 45 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-45.webp)

![Preview for 46 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-46.webp)