SERVICING

35

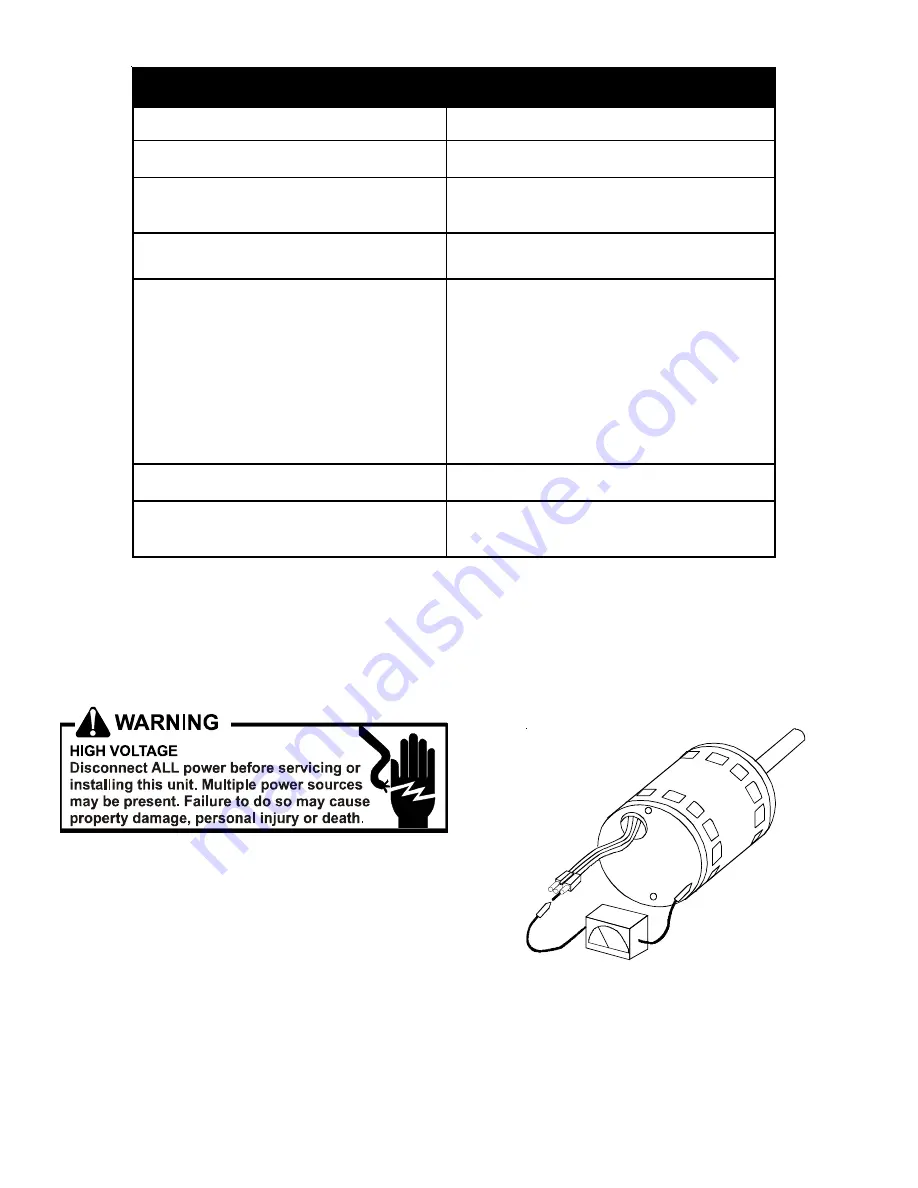

S-16C CHECKING ECM MOTOR WINDINGS

1. Disconnect the 5-pin and the 16-pin connectors from the

ECM power head.

2. Remove the 2 screws securing the ECM power head and

separate it from the motor.

3. Disconnect the 3-pin motor connector from the power head

and lay it aside.

4. Using an ohmmeter, check the motor windings for continu-

ity to ground (pins to motor shell). If the ohmmeter indi-

cates continuity to ground, the motor is defective and must

be replaced.

DO

DON'T

- Check-out motor, controls, wiring,

and connections before replacing motor.

- Automatically assume the motor is bad.

- Orient connectors down to prevent water

infiltration.

- Locate connectors above 7 and 4 o'clock

positions.

- Install "drip loops".

- Use authorized motor and control model #'s

for replacement.

- Replace one motor or control model # with

another (unless an authorized replacement).

- Keep static pressure to a minimum:

- Use high pressure drop filters - some have

1/2" H2O drop!

- Recommend high efficiency, low static

filters.

- Use restricted returns.

- Recommend keeping filters clean.

- Design ductwork for min. static, max

comfort.

- Look for and recommend ductwork

improvement, where necessary, in

replacement.

- Size the equipment wisely.

- Oversize system then compensate with low

airflow.

- Check orientation before inserting motor

connectors.

- Plug in power connector backwards.

- Force plugs.

ECM VARIABLE SPEED CIRCULATOR BLOWER MOTORS

5. Using an ohmmeter, check the windings for continuity (pin

to pin). If no continuity is indicated, the thermal limit (over

load) device may be open. Allow motor to cool and retest.

Motor

Connector

(3-pin)

Motor OK when

R > 100k ohm

(3-pin)

WINDING TEST

![Preview for 21 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-21.webp)

![Preview for 22 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-22.webp)

![Preview for 23 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-23.webp)

![Preview for 24 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-24.webp)

![Preview for 25 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-25.webp)

![Preview for 26 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-26.webp)

![Preview for 27 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-27.webp)

![Preview for 28 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-28.webp)

![Preview for 29 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-29.webp)

![Preview for 30 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-30.webp)

![Preview for 31 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-31.webp)

![Preview for 32 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-32.webp)

![Preview for 33 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-33.webp)

![Preview for 34 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-34.webp)

![Preview for 35 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-35.webp)

![Preview for 36 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-36.webp)

![Preview for 37 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-37.webp)

![Preview for 38 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-38.webp)

![Preview for 39 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-39.webp)

![Preview for 40 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-40.webp)

![Preview for 41 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-41.webp)

![Preview for 42 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-42.webp)

![Preview for 43 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-43.webp)

![Preview for 44 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-44.webp)

![Preview for 45 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-45.webp)

![Preview for 46 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-46.webp)

![Preview for 47 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-47.webp)

![Preview for 48 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-48.webp)

![Preview for 49 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-49.webp)

![Preview for 50 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-50.webp)