SERVICING

37

1. Remove the leads from the compressor terminals.

See warnings S-17 before removing compressor

terminal cover.

2. Using an ohmmeter, test continuity between ter-

minals S-R, C-R, and C-S, on single phase units or termi-

nals T1, T2 and T3, on 3 phase units.

S

R

C

COMP

OHMMETER

TESTING COMPRESSOR WINDINGS

If either winding does not test continuous, replace the com-

pressor.

NOTE:

If an open compressor is indicated allow ample time

for the internal overload to reset before replacing compressor.

S-17B Ground Test

If fuse, circuit breaker, ground fault protective device, etc., has

tripped, this is a strong indication that an electrical problem

exists and must be found and corrected. The circuit protective

device rating must be checked and its maximum rating should

coincide with that marked on the equipment nameplate.

With the terminal protective cover in place, it is acceptable to

replace the fuse or reset the circuit breaker ONE TIME ONLY

to see if it was just a nuisance opening. If it opens again, DO

NOT continue to reset.

Disconnect all power to unit, making sure that all power legs

are open.

1. DO NOT remove protective terminal cover. Disconnect the

three leads going to the compressor terminals at the near-

est point to the compressor.

Damage can occur to the glass embedded terminals if

the leads are not properly removed. This can result in

terminal and hot oil discharging.

HI-POT

COMPRESSOR GROUND TEST

2. Identify the leads and using a Megger, Hi-Potential Ground

Tester, or other suitable instrument which puts out a volt-

age between 300 and 1500 volts, check for a ground sepa-

rately between each of the three leads and ground (such

as an unpainted tube on the compressor). Do not use a

low voltage output instrument such as a volt-ohmmeter.

3. If a ground is indicated, then carefully remove the compres-

sor terminal protective cover and inspect for loose leads or

insulation breaks in the lead wires.

4. If no visual problems indicated, carefully remove the leads

at the compressor terminals.

Carefully retest for ground, directly between compressor

terminals and ground.

5. If ground is indicated, replace the compressor.

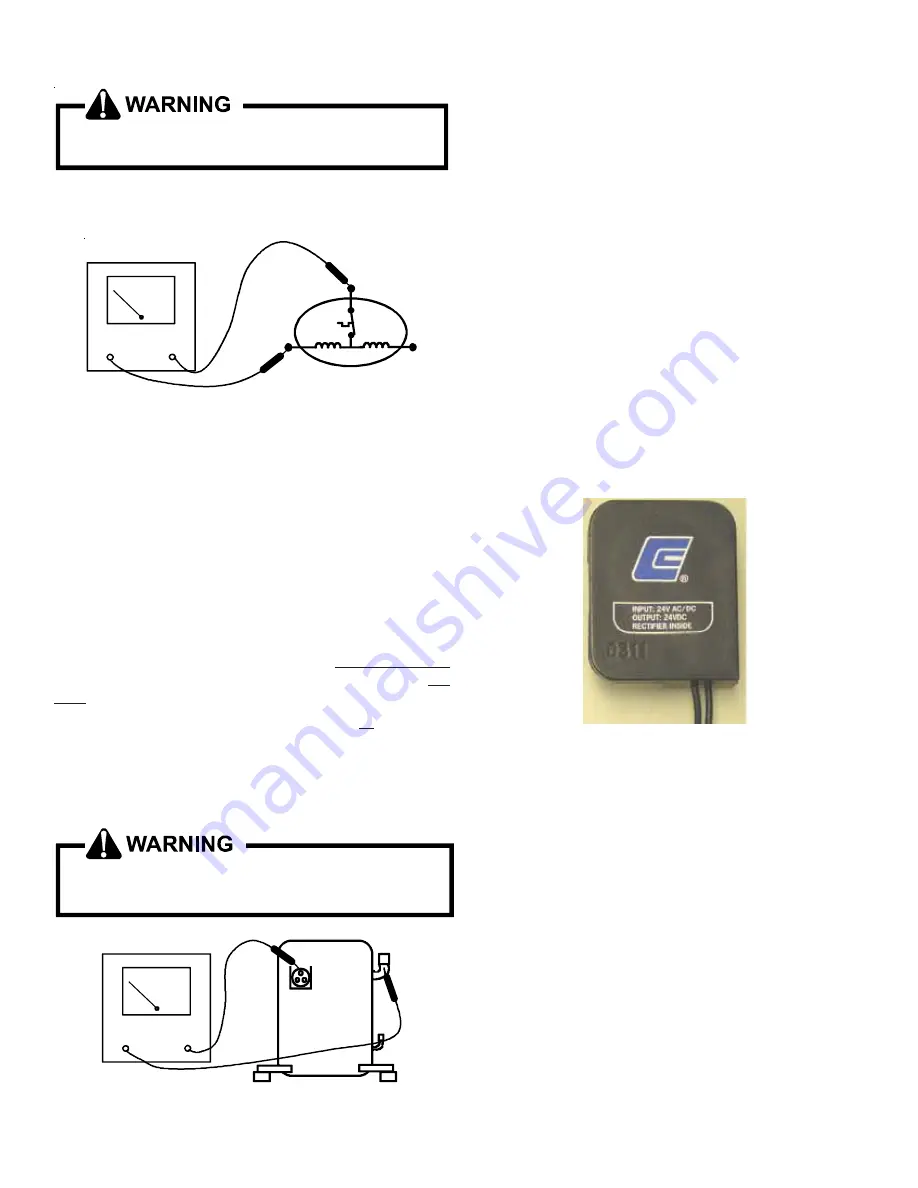

S-17C Unloader Test Procedure

A nominal 24-volt direct current coil activates the internal

unloader solenoid. The input control circuit voltage must be 18

to 28 volt ac. The coil power requirement is 20 VA. The exter-

nal electrical connection is made with a molded plug assem-

bly. This plug contains a full wave rectifier to supply direct

current to the unloader coil.

UNLOADER SOLENOID

(Molded Plug)

Unloader Test Procedure

If it is suspected that the unloader is not working, the

following methods may be used to verify operation.

1. Operate the system and measure compressor current.

Cycle the unloader ON and OFF at 10 second intervals.

The compressor amperage should go up or down at least

25 percent.

2. If step one does not give the expected results shut unit off.

Apply 18 to 28 volt ac to the unloader molded plug leads

and listen for a click as the solenoid pulls in. Remove power

and listen for another click as the unloader returns to its

original position.

3. If clicks can’t be heard, shut off power and remove the con-

trol circuit molded plug from the compressor and measure

the unloader coil resistance. The resistance should be 32

to 60 ohms, depending on compressor temperature.

![Preview for 23 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-23.webp)

![Preview for 24 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-24.webp)

![Preview for 25 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-25.webp)

![Preview for 26 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-26.webp)

![Preview for 27 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-27.webp)

![Preview for 28 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-28.webp)

![Preview for 29 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-29.webp)

![Preview for 30 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-30.webp)

![Preview for 31 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-31.webp)

![Preview for 32 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-32.webp)

![Preview for 33 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-33.webp)

![Preview for 34 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-34.webp)

![Preview for 35 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-35.webp)

![Preview for 36 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-36.webp)

![Preview for 37 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-37.webp)

![Preview for 38 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-38.webp)

![Preview for 39 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-39.webp)

![Preview for 40 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-40.webp)

![Preview for 41 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-41.webp)

![Preview for 42 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-42.webp)

![Preview for 43 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-43.webp)

![Preview for 44 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-44.webp)

![Preview for 45 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-45.webp)

![Preview for 46 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-46.webp)

![Preview for 47 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-47.webp)

![Preview for 48 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-48.webp)

![Preview for 49 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-49.webp)

![Preview for 50 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-50.webp)

![Preview for 51 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-51.webp)

![Preview for 52 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-52.webp)