SERVICING

39

S-101 LEAK TESTING

Refrigerant leaks are best detected with a halide or electronic

leak detector.

However, on outdoor installed systems, provisions must be

made to shield the copper element of an halide torch from the

sun and wind conditions in order to be able to see the element

properly.

NOTE:

The flame of the halide detector will glow green in the

presence of R-22 refrigerant.

For a system that contains a refrigerant charge and is sus-

pected of having a leak, stop the operation and hold the explor-

ing tube of the detector as close to the tube as possible, check

all piping and fittings. If a leak is detected, do not attempt to

apply more brazing to the joint. Remove and capture the charge,

unbraze the joint, clean and rebraze.

For a system that has been newly repaired and does not con-

tain a charge, connect a cylinder of refrigerant, through a gauge

manifold, to the liquid and suction line dill valves and/or liquid

line dill valve and compressor process tube.

NOTE:

Refrigerant hoses must be equipped with dill valve de-

pressors or a special adaptor used. Open the valve on the

cylinder and manifold and allow the pressure to build up within

the system. Check for and handle leaks, as described above.

After the test has been completed, remove and capture the

leak test refrigerant.

S-102 EVACUATION

This is the most important part of the entire service procedure.

The life and efficiency of the equipment is dependent upon the

thoroughness exercised by the serviceman when evacuating

air (non-condensable) and moisture from the system.

Air in a system causes high condensing temperature and pres-

sure, resulting in increased power input and reduced perfor-

mance.

Moisture chemically reacts with the refrigerant and oil to form

corrosive hydrofluoric and hydrochloric acids. These attack

motor windings and parts, causing breakdown.

The equipment required to thoroughly evacuate the system is

a high vacuum pump, capable of producing a vacuum equiva-

lent to 25 microns absolute and a thermocouple vacuum gauge

to give a true reading of the vacuum in the system

NOTE:

Never use the system compressor as a vacuum pump

or run when under a high vacuum. Motor damage could occur.

SCROLL COMPRESSORS

Do not front seat the service valve(s) with the

compressor operating in an attempt to save

refrigerant. With the suction line of the compressor

closed or severely restricted, the scroll compressor

will draw a deep vacuum very quickly. This vacuum

can cause internal arcing of the fusite, resulting in a

damaged or failed compressor.

4

50

60

70

80

90

100

110

120

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

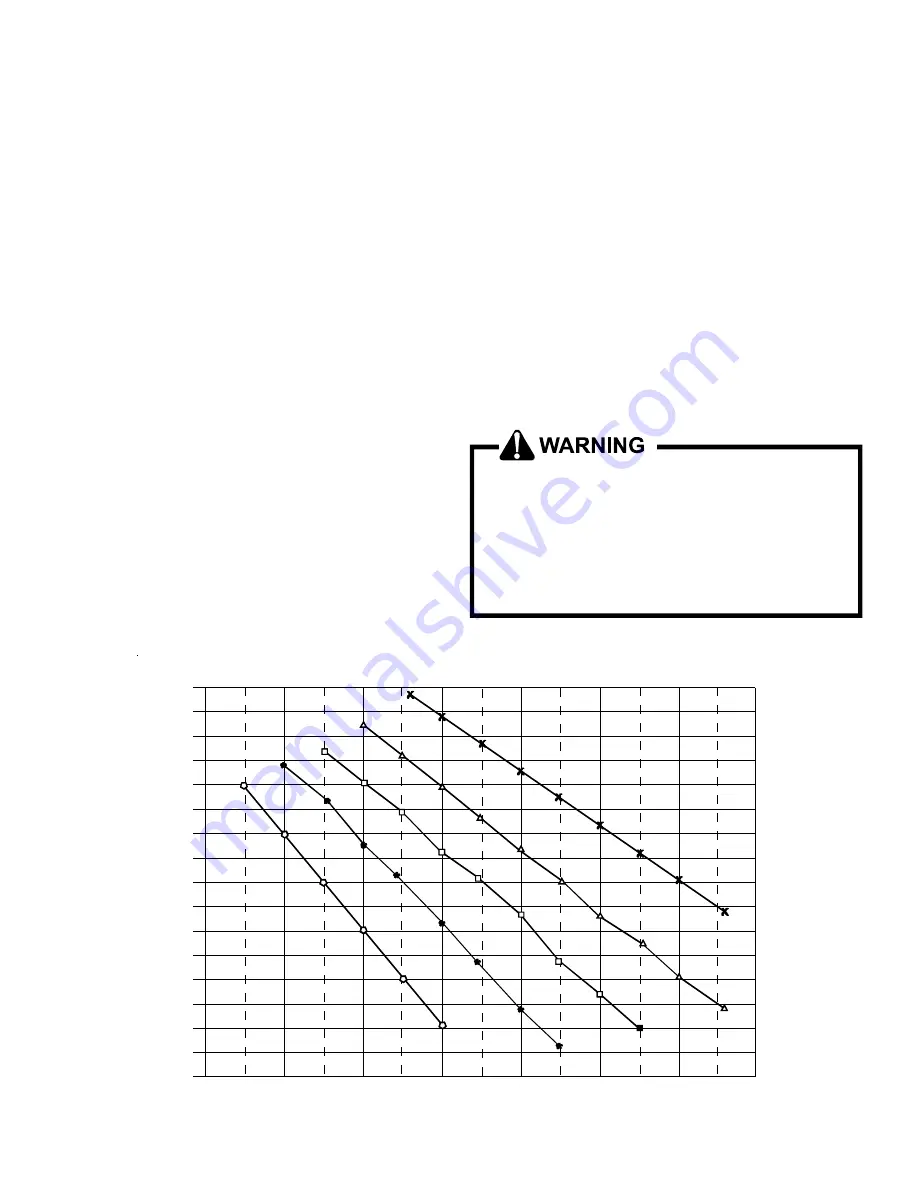

S

U

P

E

RHE

AT

@ O

.D

. UN

IT

OUTDOOR TEMPERATURE

DESIRED SUPERHEAT vs OUTDOOR TEMPERATURE

90°

F I

nd

oo

r

70

° F

In

d

o

or

75

° F

In

do

or

80

° F

In

do

or

85

° F

In

do

or

![Preview for 25 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-25.webp)

![Preview for 26 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-26.webp)

![Preview for 27 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-27.webp)

![Preview for 28 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-28.webp)

![Preview for 29 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-29.webp)

![Preview for 30 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-30.webp)

![Preview for 31 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-31.webp)

![Preview for 32 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-32.webp)

![Preview for 33 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-33.webp)

![Preview for 34 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-34.webp)

![Preview for 35 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-35.webp)

![Preview for 36 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-36.webp)

![Preview for 37 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-37.webp)

![Preview for 38 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-38.webp)

![Preview for 39 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-39.webp)

![Preview for 40 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-40.webp)

![Preview for 41 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-41.webp)

![Preview for 42 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-42.webp)

![Preview for 43 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-43.webp)

![Preview for 44 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-44.webp)

![Preview for 45 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-45.webp)

![Preview for 46 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-46.webp)

![Preview for 47 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-47.webp)

![Preview for 48 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-48.webp)

![Preview for 49 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-49.webp)

![Preview for 50 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-50.webp)

![Preview for 51 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-51.webp)

![Preview for 52 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-52.webp)