SERVICING

50

7. As the unit fires, the inclined manometer negative pressure

will drop to -1.0" ± 0.1" W.C.

8. If not as listed, replace control.

Note:

The pressure switch

must

be mounted with the diaphragm

in a vertical position.

S-311 HIGH ALTITUDE APPLICATION

High Altitude Derate - U.S. Installations Only (Optional)

High Altitude Derate is not required for proper operation. The

gas/electric units naturally derate with altitude. High Altitude

Derate kit may be installed if desired.

IMPORTANT NOTE:

The gas/electric units naturally derate

with altitude. Do not attempt to increase the firing rate by

changing orifices or increasing the manifold pressure. This

can cause poor combustion and equipment failure. At all

altitudes, the manifold pressure must be within 0.3 inches

W.C. of that listed on the nameplate for the fuel used. At all

altitudes and with either fuel, the air temperature rise must be

within the range listed on the unit nameplate. Refer to the

Installation Manual provided with the LP kit for conversion from

natural gas to propane gas and for altitude adjustments.

When this package unit is installed at high altitude, the appro-

priate High Altitude orifice kit may be installed. As altitude

increases, there is a natural reduction in the density of both

the gas fuel and combustion air. This kit will provide the proper

design certified input rate within the specified altitude range.

High altitude kits are not approved for use in Canada. For in-

stallations above 2,000 feet, use kit HA-02. The HA-02 kit is

used for both Natural and LP gas at high altitudes.

Use LPT-00A propane conversion kit for propane conversions

at altitudes below 2000 feet. Natural gas installations below

2000 feet do not require a kit.

For propane conversion above 2000 feet, high altitude kit HA-

02 is required in addition to the LPT-00A propane conversion

kit.

Natural gas and LP gas installations at altitudes > 2000 ft

2000

3000

4000

4500

5000

6000

7000

8000

U.S. BURNER ORIFICE

45/55 47/55 47/56

-

47/56 48/57 48/58 49/58

CANADA BURNER ORIFICE

45/55

-

-

48/57

-

-

-

-

2000

3000

4000

4500

5000

6000

7000

8000

U.S. BURNER ORIFICE

44/55 44/55 45/56

-

45/56 46/57 47/58 47/58

CANADA BURNER ORIFICE

44/55

-

-

47/57

-

-

-

-

2000

3000

4000

4500

5000

6000

7000

8000

U.S. BURNER ORIFICE

43/55 53/55 44/56

-

44/56 44/56 45/57 45/57

CANADA BURNER ORIFICE

43/55

-

-

46/57

-

-

-

-

ELEVATION ABOVE SEA-LEVEL (FEET)

20,000 BTUH NAT/20,OOO BTUH/L.P.

INPUT/BURNER

INPUT/BURNER

HIGH

ALTITUDE

KIT

HA02

HIGH

ALTITUDE

KIT

22,500 BTUH NAT/20,OOO BTUH/L.P.

ELEVATION ABOVE SEA-LEVEL (FEET)

HA02

HA02

INPUT/BURNER

25,000 BTUH NAT/20,OOO BTUH/L.P.

ELEVATION ABOVE SEA-LEVEL (FEET)

HIGH

ALTITUDE

KIT

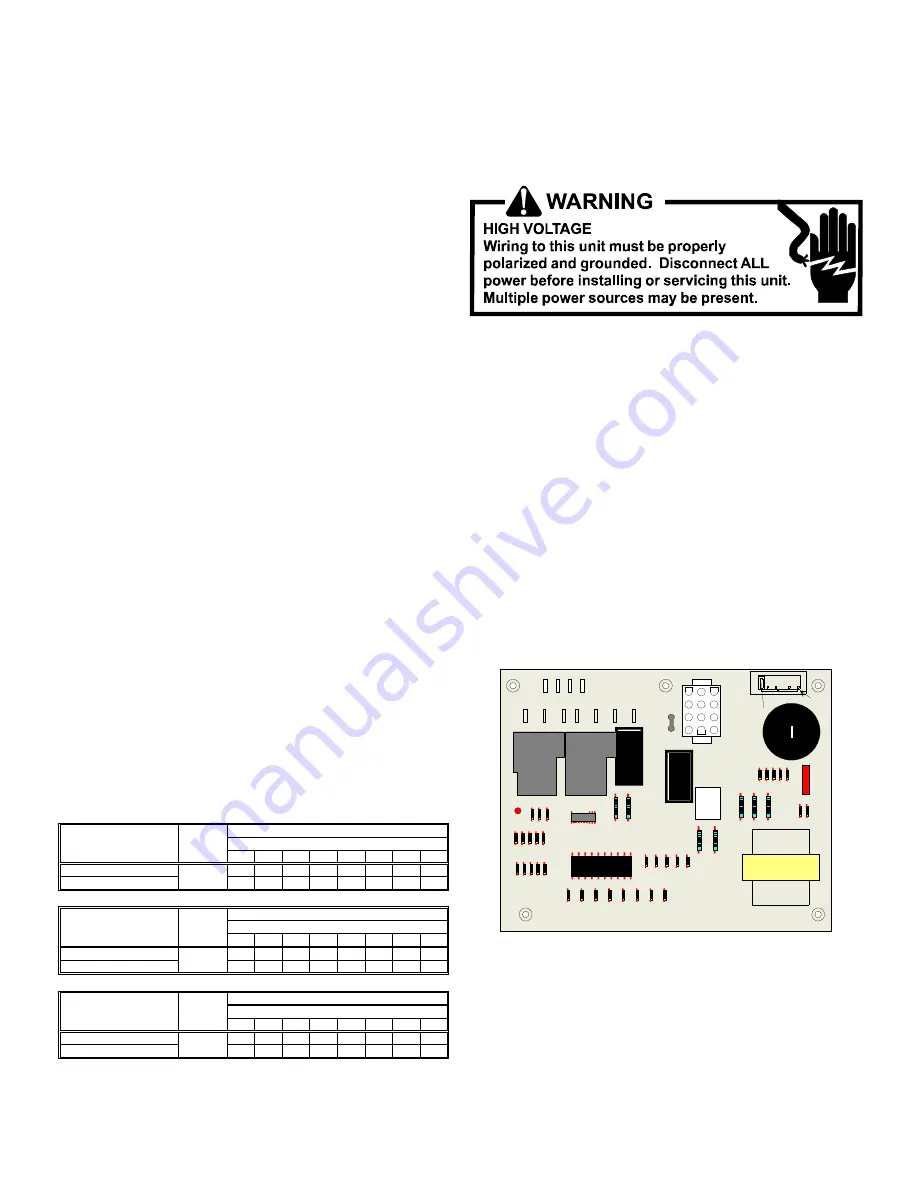

S-313 TESTING IGNITION CONTROL MODULE

NOTE:

Failure to earth ground the unit, reversing the neutral

and hot wire connection to the line (polarity), or a high resis-

tance connection in the ground or neutral lines may cause the

control to lockout due to failure to detect flame.

The ground wire must run from the unit all the way back to the

electrical panel. Proper grounding can be confirmed by dis-

connecting the electrical power and measuring resistance be-

tween the neutral (white) connection and the burner closest to

the flame sensor. Resistance should be less than 10 ohms.

DSI Direct Spark Ignition Systems

NORMAL SEQUENCE OF OPERATION (DSI Direct Spark

Ignition System)

1. Thermostat calls for heat by energizing "W". The control

checks the pressure switch for open condition. If the pres-

sure switch is closed the control will flash code "3" and

wait for the pressure switch to open.

2. The induced draft motor is energized and the control flashes

code "2" and waits for the pressure switch to close. Once

the pressure switch is closed, the LED stops flashing and

the control begins timing the 15 second pre-purge.

3

2

1

6

5

4

9

8

7

12

11

10

L2

L2

L2

L2

COOL

HEAT

UNUSED

L1

L1

D1

FS

D

iag

n

o

st

ic

L

E

D

Blower Off Delay Settings

Transformer

speed up

DSI Control Board

3. The control energizes the spark igniter and gas valve for 7

seconds. If flame is established, the control goes into a 30

second heat on delay.

4. The indoor blower is energized at the heat speed after a 30

second on delay.

5. The control monitors the safety circuit inputs, flame, and

thermostat during operation.

![Preview for 36 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-36.webp)

![Preview for 37 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-37.webp)

![Preview for 38 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-38.webp)

![Preview for 39 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-39.webp)

![Preview for 40 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-40.webp)

![Preview for 41 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-41.webp)

![Preview for 42 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-42.webp)

![Preview for 43 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-43.webp)

![Preview for 44 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-44.webp)

![Preview for 45 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-45.webp)

![Preview for 46 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-46.webp)

![Preview for 47 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-47.webp)

![Preview for 48 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-48.webp)

![Preview for 49 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-49.webp)

![Preview for 50 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-50.webp)

![Preview for 51 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-51.webp)

![Preview for 52 page of Goodman [A/G]PG Service Instructions Manual](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-52.webp)