28

If it is necessary for the installer to supply additional line voltage wiring

to the inside of the furnace, the wiring must conform to all local codes,

and have a minimum temperature rating of 105°C. All line voltage wire

splices must be made inside the furnace junction box.

The integrated control module electronic air cleaner terminals (EAC)

are energized with 115 volts whenever the circulator blower is en-

ergized.

24 V

OLT

H

UMIDIFIER

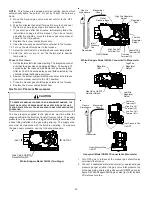

The yellow wire connected to the I.D. Blower pressure switch is

powered anytime the pressure switch is closed and provides 24

VAC humidifier control. Remove the yellow wire and connect a field

supplied jumper wire with a “piggyback” terminal to the pressure

switch terminal. Reconnect the yellow wire to the “piggyback” ter-

minal on the jumper wire and then connect the 24 VAC line of the

humidifier to the stripped end of the jumper wire. Using a wire nut

or a field-supplied quick connect terminal can make this connec-

tion. The wiring must conform to all local and national codes. Con-

nect the COM side of the humidifier to the B/C terminal on the

furnace control board (or to the COM side of the 24 VAC trans-

former).

DO NOT CONNECT 115V

HUMIDIFIER TO THESE TERMI-

NALS.

XII. GAS SUPPLY AND PIPING

G

ENERAL

The furnace rating plate includes the approved furnace gas input

rating and gas types. The furnace must be equipped to operate on

the type of gas applied. This includes any conversion kits required

for alternate fuels and/or high altitude.

T

O

PREVENT

UNRELIABLE

OPERATION

OR

EQUIPMENT

DAMAGE

,

THE

I

NLET

GAS

SUPPLY

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

WITH

ALL

OTHER

HOUSEHOLD

GAS

FIRED

APPLIANCES

OPERATING

.

CAUTION

Inlet gas supply pressures must be maintained within the ranges

specified below. The supply pressure must be constant and avail-

able with all other household gas fired appliances operating. The

minimum gas supply pressure must be maintained to prevent

unreliable ignition. The maximum must not be exceeded to pre-

vent unit overfiring.

Natural Gas

Minimum: 4.5" w.c.

Maximum: 10.0" w.c.

Propane Gas

Minimum: 11.0" w.c.

Maximum: 13.0" w.c.

Inlet Gas Supply Pressure

H

IGH

A

LTITUDE

D

ERATE

When this furnace is installed at high altitude, the appropriate High

Altitude orifice kit must be applied. This is required due to the

natural reduction in the density of both the gas fuel and combus-

tion air as altitude increases. The kit will provide the proper design

certified input rate within the specified altitude range.

High altitude kits are purchased according to the installation alti-

tude and usage of either natural or propane gas. Contact your

distributor for a tabular listing of appropriate altitude ranges and

corresponding manufacturer’s high altitude (Natural, Propane Gas,

and/or Pressure Switch) kits.

Do

not

derate the furnace by adjusting the manifold pressure to a

lower pressure than specified on the furnace rating plate. The

combination of the lower air density and a lower manifold pressure

will prohibit the burner orifice from drawing the proper amount of

air into the burner. This may cause incomplete combustion, flash-

back, and possible yellow tipping.

In some areas the gas supplier may artificially derate the gas in an

effort to compensate for the effects of altitude. If the gas is artificially

derated, the appropriate orifice size must be determined based upon

the BTU/ft

3

content of the derated gas and the altitude. Refer to the

National Fuel Gas Code, NFPA 54/ANSI Z223.1, and information pro-

vided by the gas supplier to determine the proper orifice size.

A different pressure switch may be required at high altitude regardless

of the BTU/ft

3

content of the fuel used. Contact your distributor for a

tabular listing of appropriate altitude ranges and corresponding

manufacturer’s pressure switch kits.

P

ROPANE

G

AS

C

ONVERSION

P

OSSIBLE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

MAY

OCCUR

IF

THE

CORRECT

CONVERSION

KITS

ARE

NOT

INSTALLED

. T

HE

APPROPRIATE

KITS

MUST

BE

APPLIED

TO

ENSURE

SAFE

AND

PROPER

FURNACE

OPERATION

. A

LL

CONVERSIONS

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALLER

OR

SERVICE

AGENCY

.

WARNING

This unit is configured for natural gas. The appropriate

manufacturer’s propane gas conversion kit, must be applied for

propane gas installations. Refer to the

Section VIII, Propane Gas

/ High Altitude Installations

section for details.

Consult the furnace Specification Sheet for a listing of appropirate

kits. The indicated kits must be used to insure safe and proper

furnace operation. All conversions must be performed by a quali-

fied installer or service agency.

G

AS

V

ALVE

This unit is equipped with a 24 volt gas valve controlled during

furnace operation by the integrated control module. As shipped,

the valve is configured for natural gas. The valve is field convertible

for use with propane gas by replacing the regulator spring with a

propane gas spring from an appropriate manufacturer’s propane

gas conversion kit. Taps for measuring the gas supply pressure

and manifold pressure are provided on the valve.

The gas valve has a manual ON/OFF control located on the valve

itself. This control may be set only to the “ON” or “OFF” position.

Refer to the lighting instructions label or

Section XIV, Startup Pro-

cedure & Adjustment

for use of this control during start up and shut

down periods.

G

AS

P

IPING

C

ONNECTIONS

G

ENERAL

CAUTION

T

O AVOID POSSIBLE UNSATISFACTORY OPERATION OR EQUIPMENT DAMAGE

DUE TO UNDERFIRING OF EQUIPMENT, USE THE PROPER SIZE OF

NATURAL/PROPANE GAS PIPING NEEDED WHEN RUNNING PIPE FROM THE

METER/TANK TO THE FURNACE.

When sizing a trunk line, be sure to include all appliances which

will operate simultaneously.

The gas piping supplying the furnace must be properly sized based

on the gas flow required, specific gravity of the gas, and length of

the run. The gas line installation must comply with local codes, or

in their absence, with the latest edition of the National Fuel Gas

Code, NFPA 54/ANSI Z223.1.