24

H

ORIZONTAL

I

NSTALLATIONS

R

IGHT

S

IDE

D

OWN

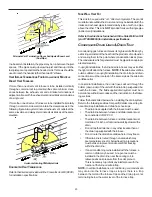

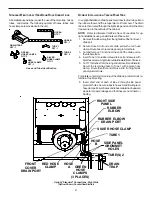

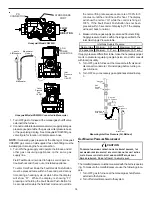

Horizontal installations with the right side down require that the

drain hoses be connected to the right side front cover drain port

and the rubber elbow drain port.

NOTE:

On counterflow models, relocation of the front cover

pressure switch hose is required.

Make connections as follows:

1. Remove the rubber plug/cap from right side of the front

cover drain port.

Counterflow furnaces

Relocate the front cover pressure switch hose connection

from the left side pressure tap to the right (down) side tap.

The pressure switch hose must be connected to the down

side to guard against blocked drain conditions. Cut hose

to appropriate length to minimize sagging. Plug left

(unused) pressure tap with plug removed from right side.

2. Secure Hose A to front cover drain tap with a red hose

clamp. Route hose to rear right (down) side panel grommet

holes.

3. Cut 1/4 inch from the end of the drain port on the rubber

elbow and discard.

4. Insert Tube 1 into rubber elbow drain port and secure with

a silver hose clamp. Angle tube outward toward front of

furnace.

5. Cut 17 3/4 inches from the long end of Hose B and discard.

6. Secure remaining end of Hose B to exposed end of Tube

1 with a green hose clamp. Route hose to front right

down side panel grommet holes.

7. Cut 5 1/2 inches straight length from the long end of each

Tube 2 and discard the radius pieces.

8. Insert approximately one inch of each Tube 2 through the

right down side panel grommet holes. Secure tubes to

Hose A and Hose B using green hose clamps. Ensure

hoses and tubes maintain a downward slope for proper

drainage and are not kinked or bound.

For details concerning mounting of the drain trap, refer to

Con-

densate Drain Lines and Drain Trap - Horizontal Drain Trap Mount-

ing.

When using the horizontal alternate

vent configuration, you must use the

RF000142 vent drain kit.

Horizontal Connections - Right Side Down

(Upflow Shown, Counterflow Similar)

VENT-DRAIN

“FIELD-SUPPLIED

DRAIN HOSE”

“FIELD-SUPPLIED

CONNECTOR”

FROM VENT-DRAIN

CONNECTED TO

CONDENSATE

DRAIN LINE WITH

NOTE:

MAKE

SMALL

LOOP IN HOSE

TO SERVE

AS

“P-TRAP”

HOSE A

HOSE B

GREEN

HOSE

CLAMP

(3 PLACES)

TUBE 1

RUBBER

ELBOW

RIGHT

SIDE

PANEL

DRAIN TRAP

Allow 4-3/4”

minimum

for trap

TUBES 2

RUBBER ELBOW

DRAIN PORT

FRONT COVER

DRAIN PORT

FRONT

COVER

PRESSURE

TAP

RED HOSE

CLAMP

SILVER HOSE

CLAMP