9

deicing salts or chemicals

carbon tetrachloride

halogen type refrigerants

cleaning solutions (such as perchloroethylene)

printing inks

paint removers

varnishes

hydrochloric acid

cements and glues

antistatic fabric softeners for clothes dryers

and masonry acid washing materials

•

Seal off a

non-direct vent

furnace if it is installed near an

area frequently contaminated by any of the above

substances. This protects the

non-direct vent

furnace

from airborne contaminants. To ensure that the

enclosed

non-direct

vent

furnace has an adequate supply

of combustion air, vent from a nearby uncontaminated

room or from outdoors. Refer to the

Combustion and

Ventilation Air Requirements

for details.

•

If the furnace is used in connection with a cooling coil

unit, install the furnace upstream or in parallel with the

cooling coil unit. Premature heat exchanger failure will

result if the cooling unit is placed ahead of the furnace.

•

If the furnace is installed in a residential garage, position

the furnace so that the burners and ignition source are

located not less than 18 inches (457 mm) above the

floor. Protect the furnace from physical damage by

vehicles.

•

If the furnace is installed horizontally, ensure the access

doors are not on the “up/top” or “down/bottom” side of the

furnace.

•

Do not connect this furnace to a chimney flue that serves

a separate appliance designed to burn solid fuel.

•

On Counterflow Installations, the air conditioning coil must

be downstream on the supply (positive) side of the furnace

heat exchanger.

•

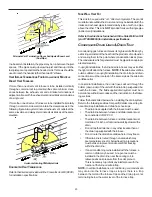

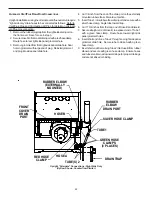

Counterflow Installation over a noncombustible floor.

Before setting the furnace over the plenum opening, ensure

the surface around the opening is smooth and level. A

tight seal should be made between the furnace base and

floor by using a silicone rubber caulking compound or

cement grout.

•

Counterflow Installation over a combustible floor.

If

installation over a combustible floor becomes necessary,

use an accessory subbase (see Specification Sheet

applicable for your model for details.) A special accessory

subbase must be used for upright counterflow unit

installations over any combustible material including wood.

Refer to subbase instructions for installation details. Follow

the instructions with the subbase for proper installation.

Do not install the furnace directly on carpeting, tile, or

other combustible material other than wood flooring.

(

NOTE

: The subbase will not be required if an air

conditioning coil is installed between the supply air

opening on the furnace and the floor.)

C

LEARANCES

AND

A

CCESSIBILITY

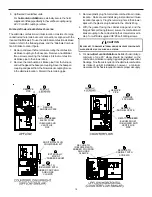

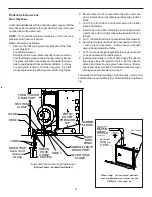

Installations must adhere to the clearances to combustible mate-

rials to which this furnace has been design certified. The minimum

clearance information for this furnace is provided on the unit’s clear-

ance label. These clearances must be permanently maintained.

Clearances must also accommodate an installation’s gas, electri-

cal, and drain trap and drain line connections. If the alternate

combustion air intake or vent/flue connections are used additional

clearance must be provided to accommodate these connections.

Refer to

Vent/Flue Pipe and Combustion Air Pipe

for details.

NOTE:

In addition to the required clearances to combustible materials, a

minimum of 24 inches service clearance must be available in front

of the unit.

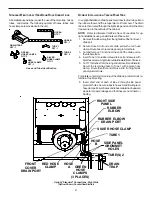

T O P

B O T T O M

S ID E

S ID E

S ID E

T O P

B O T T O M

U pflow

C ou nte rflo w

H orizo n ta l

A furnace installed in a confined space (i.e., a closet or utility

room) must have two ventilation openings with a total minimum

free area of 0.25 square inches per 1,000 BTU/hr of furnace input

rating. Refer to Specification Sheet applicable to your model for

minimum clearances to combustible surfaces. One of the ventila-

tion openings must be within 12 inches of the top; the other open-

ing must be within 12 inches of the bottom of the confined space.

In a typical construction, the clearance between the door and door

frame is usually adequate to satisfy this ventilation requirement.

E

XISTING

F

URNACE

R

EMOVAL

NOTE:

When an existing furnace is removed from a venting sys-

tem serving other appliances,

the venting system may be too large

to properly vent the remaining attached appliances.

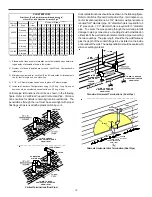

The following vent testing procedure is reproduced from the

Ameri-

can National Standard/National Standard of Canada for Gas-

Fired Central Furnaces ANSI Z21.4, CSA-2.3 latest edition

Section 1.23.1.

The following steps shall be followed with each appliance con-

nected to the venting system placed in operation, while any

other appliances connected to the venting system are not in

operation:

1. Seal any unused openings in the venting system;

2. Inspect the venting system for proper size and horizon-

tal pitch, as required by the National Fuel Gas Code,

ANSI Z223.1 or the Natural Gas and Propane Installa-

tion Code, CSA B149.1-05 and these instructions. De-

termine that there is no blockage or restriction, leak-

age, corrosion and other deficiencies which could cause

an unsafe condition.