10

0.1"

0.2"

0.3"

0.4"

0.5"

High

1155

1090

1025

950

895

ARUF172916

Med.

940

890

860

815

755

Low

695

665

650

610

550

High

1155

1090

1025

950

895

ARUF182416

Med.

940

890

860

815

755

Low

695

665

650

610

550

High

1135

1085

1025

965

915

ARUF193116

Med.

860

825

780

750

680

Low

600

570

545

500

465

High

1385

1315

1240

1155

1065

ARUF303016

Med.

1340

1290

1230

1140

1050

Low

1075

1030

980

910

840

High

1310

1240

1155

1090

1020

ARUF363616

Med.

1270

1210

1140

1075

980

Low

1045

1005

955

885

805

High

1700

1660

1625

1545

1505

ARUF364216

Med.

1500

1440

1400

1350

1345

Low

1330

1300

1250

1230

1220

High

2065

2000

1925

1860

1780

ARUF374316

Med.

1685

1635

1550

1470

1410

Low

1490

1425

1345

1280

1205

High

2150

2120

2070

2000

1940

ARUF486016

Med.

1940

1930

1905

1860

1790

Low

1610

1600

1590

1575

1550

High

2150

2105

2040

1970

1880

ARUF496116

Med.

1960

1935

1895

1825

1750

Low

1670

1625

1585

1525

1455

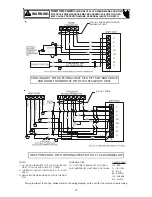

CFM deliverd against External Static Pressure

Model

Speed

NOTE: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

0.1"

0.2"

0.3"

0.4"

0.5"

H igh

1155

1090

1025

950

895

ARPF18241*

Med.

940

890

860

815

755

Low

695

665

650

610

550

H igh

1135

1085

1025

965

915

ARPF19311*

Med.

860

825

780

750

680

Low

600

570

545

500

465

H igh

1385

1315

1240

1155

1065

ARPF30301*

Med.

1340

1290

1230

1140

1050

Low

1075

1030

980

910

840

H igh

1310

1240

1155

1090

1020

ARPF36361*

Med.

1270

1210

1140

1075

980

Low

1045

1005

955

885

805

H igh

1700

1660

1625

1545

1505

ARPF36421*

Med.

1500

1440

1400

1350

1345

Low

1330

1300

1250

1230

1220

H igh

2065

2000

1925

1860

1780

ARPF37431*

Med.

1685

1635

1550

1470

1410

Low

1490

1425

1345

1280

1205

H igh

2150

2120

2070

2000

1940

ARPF48601*

Med.

1940

1930

1905

1860

1790

Low

1610

1600

1590

1575

1550

H igh

2150

2105

2040

1970

1880

ARPF49611*

Med.

1960

1935

1895

1825

1750

Low

1670

1625

1585

1525

1455

CFM deliverd against External Static Pressure

Model

Speed

NOTE: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

0.1"

0.2"

0.3"

0.4"

0.5"

High

1,155

1,090

1,025

950

895

AD PF18241/16

Med.

940

890

860

815

755

Low

695

665

650

610

550

High

1,700

1,660

1,625

1,545

1,505

AD PF30421/16

Med.

1,500

1,440

1,400

1,350

1,345

Low

1,370

1,300

1,250

1,230

1,220

High

2,150

2,120

2,070

2,000

1,940

AD PF48601/16

Med.

1,940

1,930

1,905

1,860

1,790

Low

1,610

1,600

1,590

1,575

1,550

CFM deliverd against External Static Pressure

Model

Speed

NOTE: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

0.1"

0.2"

0.3"

0.4"

0.5"

High

1155

1090

1025

950

895

ATUF182416

Med.

875

830

790

750

715

Low

640

610

570

535

490

High

1135

1085

1025

965

915

ATUF193116

Med.

860

825

780

750

680

Low

600

570

545

500

465

High

1455

1385

1330

1205

1090

ATUF303016

Med.

1340

1290

1230

1140

1050

Low

1075

1030

980

910

840

High

1345

1290

1230

1150

1070

ATUF363616

Med.

1270

1210

1140

1075

980

Low

1045

1005

955

885

805

High

1700

1680

1645

1610

1535

ATUF364216

Med.

1500

1480

1440

1380

1325

Low

135

1320

1275

1230

1195

High

2065

2000

1925

1860

1780

ARUF374316

Med.

1685

1635

1550

1470

1410

Low

1490

1425

1345

1280

1205

High

2135

2080

1985

1900

1805

ATUF486016

Med.

1975

1935

1875

1775

1675

Low

1715

1670

1650

1590

1530

CFM deliverd against External Static Pressure

Model

Speed

NOTE: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

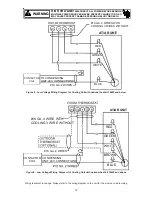

ASPF Motor

The ASPF air handler features an energy efficient blower

motor. The motor is a constant torque motor with very low

power consumption. The motor is energized by 24 VAC. Ad-

just the CFM by changing the 24 VAC leads to the desired

speed on the terminal block.

The ASPF motor blower speed is programmed to deliver ad-

equate airflow at rated external static pressure and with 60

second off time delay. For details, refer to the specification

sheet applicable to your model.

CFM Delivery

Table 13 shows the CFM speed tap settings for the ASPF.

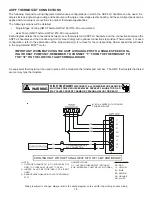

Thermostats

NOTE:

Second Stage heat can be accomplished by multi-

stage heating thermostat or the addition of an outdoor