4

Pre-Installation Instructions

Carefully read all instructions for the installation prior to in-

stalling product. Make sure each step or procedure is under-

stood and any special considerations are taken into account

before starting installation. Assemble all tools, hardware

and supplies needed to complete the installation. Some items

may need to be purchased locally. Make sure everything

needed to install the product is on hand before starting.

Location

NOTE:

Air handlers are designed for

indoor installation

only

.

Give special consideration to minimizing the length of refrig-

erant tubing when installing air handlers. Refer to Remote

Cooling/Heat Pump Service Manual, TP-106 Long Line Set

Application R-22 or TP-107 Long Line Set Application R-410A

for guidelines. The unit clearance from a combustible sur-

face may be 0". However, service clearance is to take prece-

dence. In addition allow a minimum of 24" in front of the unit

for service clearance.

Do not install the air handler in a location that violates the

instructions provided with the condenser.

If the unit is located in an area with high ambient temperature

and/or high humidity the air handler maybe subject to nui-

sance sweating of the casing. On these installations a wrap

of 2” fiberglass insulation with a vapor barrier is recom-

mended.

Consult all appropriate regulatory codes prior to determining

final clearances. When installing this unit in an area that may

become wet, elevate the unit with a sturdy, non-porous ma-

terial. In installations that may lead to physical damage (i.e. a

garage) it is advised to install a protective barrier to prevent

such damage.

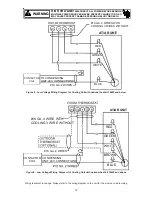

Ductwork

This air handler is designed for a complete supply and return

ductwork system.

Do not operate this product without all the ductwork

attached.

To ensure correct system performance, the ductwork is to be

sized to accommodate 375-425 CFM per ton of cooling with

the static pressure not to exceed .5" WC. Inadequate duct

work that restricts airflow can result in improper performance

and compressor or heater failure. Ductwork is to be con-

structed in a manner that limits restrictions and maintains

suitable air velocity. Ductwork is to be sealed to the unit in a

manner that will prevent leakage.

Return Ductwork

DO NOT TERMINATE THE RETURN DUCTWORK IN AN

AREA THAT CAN INTRODUCE TOXIC, OR OBJECTION-

ABLE FUMES/ODORS INTO THE DUCTWORK. The return

ductwork is to be introduced into the air handler bottom (upflow

configuration).

Return Air Filters

Each installation must include a return air filter. This filtering

may be performed at the air handler or externally such as a

return air filter grille. Air handlers mounted in the downflow

orientation, including “B” series, require external filtering. A

washable filter is available as an accessory. To ensure opti-

mum performance frequent filter cleaning is advised. Refer

to

Table 1

for the appropriate filter.

ATUF

ARUF

ARPF

ADPF ASPF

Filter

Number

Qty

Required

1729

1824

3030

3030

1931

1931

3636

3636

3642

3642

3042

3036

3743

3743

3137

4860

4860

4860

4260

1

FIL 48-61

1

3030

1830

FIL 36-42

1

1824

1824

N/A

FIL 18-32

Table 1

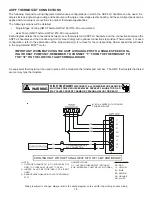

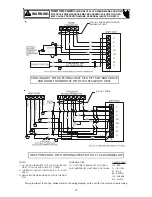

Electric Heat

Refer to this manual in combination with the instructions pro-

vided with the heat kit for the correct installation procedure.

The air handlers listed in this manual do not have factory

installed electric heat. Electric heat is available as an acces-

sory. If installing this option, the

ONLY

heat kits that can be

used are the HKR series.

NOTE:

The Amana® brand EHK, ECB, EDB, and EDK kits

are

NOT

approved for use with these air handlers.

The heating mode temperature rise is dependent upon the

system airflow, the supply voltage, and the heat kit size (kW)

selected. Use

Tables 2, 3, and 4

to determine the tempera-

ture rise (

º

F).

3

5

6

8

10

15

20

21

600

18

28

35

41

800

13

21

26

31

42

1000

11

17

21

25

34

50

1200

9

14

18

21

28

42

56

62

1400

8

12

15

18

24

36

48

53

1600

7

10

13

15

21

31

42

46

1800

6

9

12

14

19

28

37

41

2000

5

8

11

12

17

25

34

37

HEAT KIT NOMINAL kW

CFM

Table 2

230/1/60 Supply Voltage - Temperature Rise Table °F

3

5

6

8

10

15

20

21

600

17

27

34

39

800

13

20

25

30

40

1000

10

16

20

24

32

48

1200

8

13

17

20

27

40

53

59

1400

7

11

14

17

23

34

46

51

1600

6

10

13

15

20

30

40

44

1800

6

9

11

13

18

27

36

39

2000

5

8

10

12

16

24

32

35

CFM

HEAT KIT NOMINAL kW

Table 3

220/1/60 Supply Voltage - Temperature Rise Table °F