7

Downflow Conversion

Conversion to downflow MUST be performed in an area that

allows access to all sides prior to placing the air handler in its

final location. To prevent the evaporator coil pan from “sweat-

ing” the DPI accessory insulation kit is to be used when per-

forming this conversion. NOTE: The DPI kit is not supplied

with this product and is to be purchased separately. See

Table 7

for the correct DPI kit.

ASPF

Insulation Kit

1830

DPI36-42/20

3137 / 4260

DPI48-61/20

Table 7

Refer to

Figures 3 through 5

for the location of the compo-

nents referenced in the following steps.

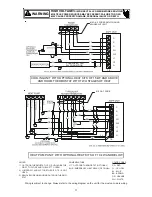

Figure 3

illustrates

the new installation location for the removed components.

1. Before inverting the air handler, remove all access pan-

els, the coil rear channel bracket, and the filter close-off

panel.

2. Remove the evaporator coil and the horizontal drain pan.

Discard horizontal drain pan.

3. Install the provided plastic plug into the vacated access

panel.

4. Remove the two (2) zee coil support brackets and insu-

lation retaining brackets.

5. Remove the tie bracket.

6. Install the DPI Insulation Kit onto the bottom of the drain

pan.

NOTE: The filter provision is not applicable

in THIS downflow application.

ACCESS

PANEL

RETURN AIR SIDE

OF UNIT

REAR CHANNEL

BRACKET

ZEE COIL

SUPPORT BRACKET

COIL RETAINING

BRACKET

TIE BRACKET

Figure 3

7. Install the zee coil supports and the wrapper stiffeners.

8. Install the tie bracket.

9. Install the rear channel bracket.

10. To prevent possible condensate “blow off” the insula-

tion retainers are to be laid into the evaporator coil pan

as shown in

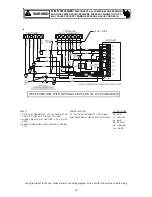

Figure 4.

3” FLAT INSULATION

RETAINER

(BOTH SIDES)

Figure 4

To complete the conversion, slide the evaporator coil into

the chassis and attach the three (3) access panels.

(Figure

5).

WRAPPER

INSULATION

JACKET

ZEE COIL

SUPPORT

WRAPPER

STIFFENER

DRAIN PAN

INSULATION KIT

BLOWER

ASSEMBLY

Figure 5

NOTE:

When converted to downflow position, the coil may

protrude above the cabinet on some models.

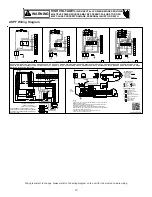

Horizontal Conversion

The only field modification required for conversion to “Hori-

zontal Right-Hand” is the removal of the plastic knockouts in

the horizontal panel drain connections. To prevent the hori-

zontal drain pan from sweating in high humidity applications,

it is recommended that a DPIH insulation accessory kit be

used. NOTE: The DPIH insulation kit is not supplied with this

product and should be purchased separately. See

Table 8

for the correct DPIH kit.