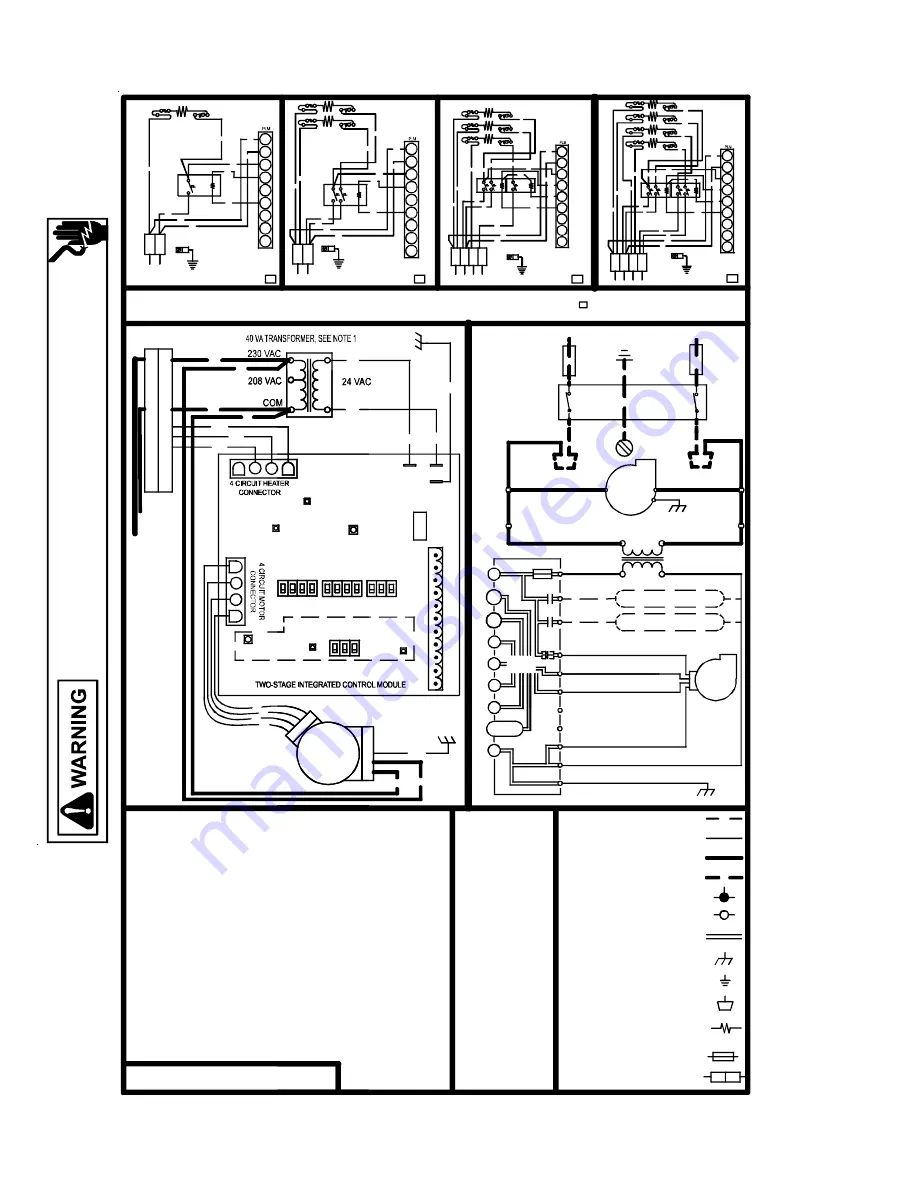

WIRING DIAGRAMS

10

HIGH VOL

T

A

G

E

!

DIS

C

ONNECT

AL

L

POW

E

R BEF

O

RE

SERVICI

NG OR IN

S

T

A

L

L

IN

G

T

H

IS

UNIT

.

M

U

L

T

IPL

E

PO

W

E

R SO

UR

CES M

A

Y BE P

R

ESEN

T

.

F

A

IL

URE

T

O

DO

SO

M

A

Y CAUS

E PRO

P

ERTY DAM

A

G

E

,

PERSO

NAL

I

N

J

U

R

Y

O

R

DE

A

T

H

.

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

AVPTC

RD

M4

FL

B L

RD

3

B K

BK

L2

R D

Y L

8

BK

RD

3

L1

RD

RD

5

BK

FL

TL

FOUR (4) ELEMENT ROWS

M2

HTR 1

4

1

5

M5

2

M2

R

L2

L1

L1

4

R D

B L

L2

FL

1

3

7

RD

THREE (3) ELEMENT ROWS

TL

L2

BL

B L

2

RD

M8

7

RD

5

7

B K

BL

BK

Y L

PU

1

BR

Y L

FL

TL

9

BK

M1

7

WH

6

BK

RD

BR

TL

B K

5

M1

WH

2

M1

HTR1

PU

M6

BK

FL

HTR 1

TL

HTR 4

R1

PU

M2

FL

B K

4

6

RD

P U

BK

RD

BK

6

M3

B L

B K

WH

9

M3

B K

R1

M4

RD

8

RD

9

HTR 3

R2

4

L1

TL

L1

B L

FL

RD

HTR2

Y L

M3

M2

TL

HTR3

TL

ONE (1) ELEMENT ROWS

B L

B K

M1

BK

1

BK

3

M1

RD

L2

9

R2

HTR 2

M2

M4

BK

L1

8

TWO (2) ELEMENT ROWS

TL

TL

NOTE : WHEN INSTALLING HEATER KIT, ENSURE SPEED TAP DOES NOT EXCEED MINIMUM BLOWER SPEED (MBS) SPEC IFIED FOR THE AIRHANDLER/HEAT ER

HTR 2

B L

R

6

RD

FL

Y L

M7

2

WH

BK

RD

FL

FL

L2

8

HTR 1

BK

B K

Y L

RD

BK

GY

BL

AF

HE

A

T

COM

CIRCULATOR BLOWER

2. MANUFACTURER'S SPECIFIED REPLACEMENT PARTS MUST BE USED

WHEN SERVICING.

1

1

SEE

NOTE 5

BK BLACK

OR ORANGE

CIRCULATOR

CIRCULATOR

RD

WH

TO

MICRO

R

W2 (2)

AIR

DIAGNOSTIC

LED

PL1

BL BLUE

4

2

PK PINK

EQUIPMENT GND

SEE

NOTE

7

DE

HU

M

TERMINAL

GY GRAY

O

PLUG CONNECTION

DEHUM

RD RED

24 VAC

RD

FUSE

4

-

BLWR

LEARN

5

DIP SWITCHES

AIR

40 VA

AD

J

U

S

T

2

3

LOW VOLTAGE FIELD

1

3

3

HI VOLTAGE FIELD

8

L1

9

INDOOR

7

4. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO N.E.C. AND

LOCAL CODES.

BI

A

S

4

BK

1

5

BL

PL2

W H WHITE

FUSE 3 A

208/230 VAC

GND

JUNCTION

ECM MOTOR

HARNESS

GND

6

L2

6

L1

COM

BR

G

VT VIOLET

UN

U

S

E

D

MARK ACCORDING TO NUMBER OF HEATER ELEMENT ROW S INSTALLED. NO MARK INDICATES NO HEAT KIT INSTALLED.

G

INTEGRATED CONTROL MODULE

O

1

2

W2

6. BIAS AND TERM DIP SWITCHES MUST BE IN "ON" POSITION. RED

STATUS LED PROVIDES NETWORK STATUS. GREEN RX LED INDICATES

NETWORK TRAFFIC. USE LEARN BUTTON TO RESET NETWORK.

BI

A

S

BK

3

HI VOLTAGE (230V)

3. IF ANY OF THE ORIGINAL WIRES AS SUPPLIED WITH THIS UNIT

MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING

MATERIAL HAVING A TEMPERATURE RATING OF AT LEAST 105°C.

USE COPPER CONDUCTORS ONLY

RX LED

4

2

4

V

T

H

E

R

M

O

ST

AT

CON

NE

C

T

ION

S

7. DISCARD CONNECTOR PL1 WHEN INSTALLING OPTIONAL HEAT KIT

1. PLACE RED WIRE ON TRANSFORMER TERMINAL 2 FOR 208 VAC

OPERATION.

YL YELLOW

W2

L2

1

DISCONNECT

KIT COMBINATION ON THIS UNIT'S S&R PLATE. AFTER INSTALLING OP TIONAL HEAT KIT, MARK AN "X" IN THE PROVIDED ABOVE.

BR BROWN

SEE NOTE 6

2

BL

Y2

BK

RESISTER

TR

C

1

3

GND (4)

2

2

PROT. DEVICE

INDOOR

INTEGRATED CONTROL

9

RD

TH

+VDC (1)

Y1

5. TO RECALL THE LAST 6 FAULTS, MOST RECENT TO LEAST RECENT,

DEPRESS SWITCH FOR MORE THAN 2 SECONDS WHILE IN STANDBY (N

THERMOSTAT INPUTS)

EL

EC

STATUS

LED

TH

B

K

Y2

COLOR CODES:

RX (2)

RD

GND

4

24 V

3 A

W1

GND

4

LOW VOLTAGE (24V)

NOTES:

GN

Y1

R

CFM LED

W1

8

FIELD SPLICE

5

W1 (1)

C

R

D

DEHUM

TX (3)

BL

INTERNAL TO

3

FIELD GND

GND

TE

R

M

HEAT SEQUENCER R2

RD

TRANSFORMER

DE

L

A

Y

CO

O

L

GN GREEN

2

4

V

T

H

ER

M

O

ST

A

T

CO

NN

E

C

T

IO

N

S

HEAT SEQUENCER R1

GN

7

TR

OVERCURRENT

2

BLWR

0140A00039 REV.C

6. BIAS AND TERM DIP SWITCHES MUST BE IN "ON" POSITION. RED

STATUS LED PROVIDES NETWORK STATUS. GREEN RX LED INDICATES

NETWORK TRAFFIC. USE LEARN BUTTON TO RESET NETWORK.

7. DISCARD CONNECTOR PL1 WHEN INSTALLING OPTIONAL HEAT KIT

2. MANUFACTURER'S SPECIFIED REPLACEMENT PARTS MUST BE USED

4. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO N.E.C. AND

3. IF ANY OF THE ORIGINAL WIRES AS SUPPLIED WITH THIS UNIT

MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING

MATERIAL HAVING A TEMPERATURE RATING OF AT LEAST 105°C.

USE COPPER CONDUCTORS ONLY

1. PLACE RED WIRE ON TRANSFORMER TERMINAL 2 FOR 208 VAC

5. TO RECALL THE LAST 6 FAULTS, MOST RECENT TO LEAST RECENT,

DEPRESS SWITCH FOR MORE THAN 2 SECONDS WHILE IN STANDBY (N

CIRCULATOR BLOWER

4

2

3

4

2

3

1

ECM MOTOR

ECM MOTOR

HARNESS

3

1

ECM MOTOR

1

2

SEE

NOTE 5

DE

HU

M

DIP SWITCHES

AD

J

U

S

T

1

BI

A

S

UN

U

S

E

D

BI

A

S

SEE NOTE 6

BL

EL

EC

STATUS

LED

4

CFM LED

5

TE

R

M

DE

L

A

Y

CO

O

L

0140A00039 REV.C