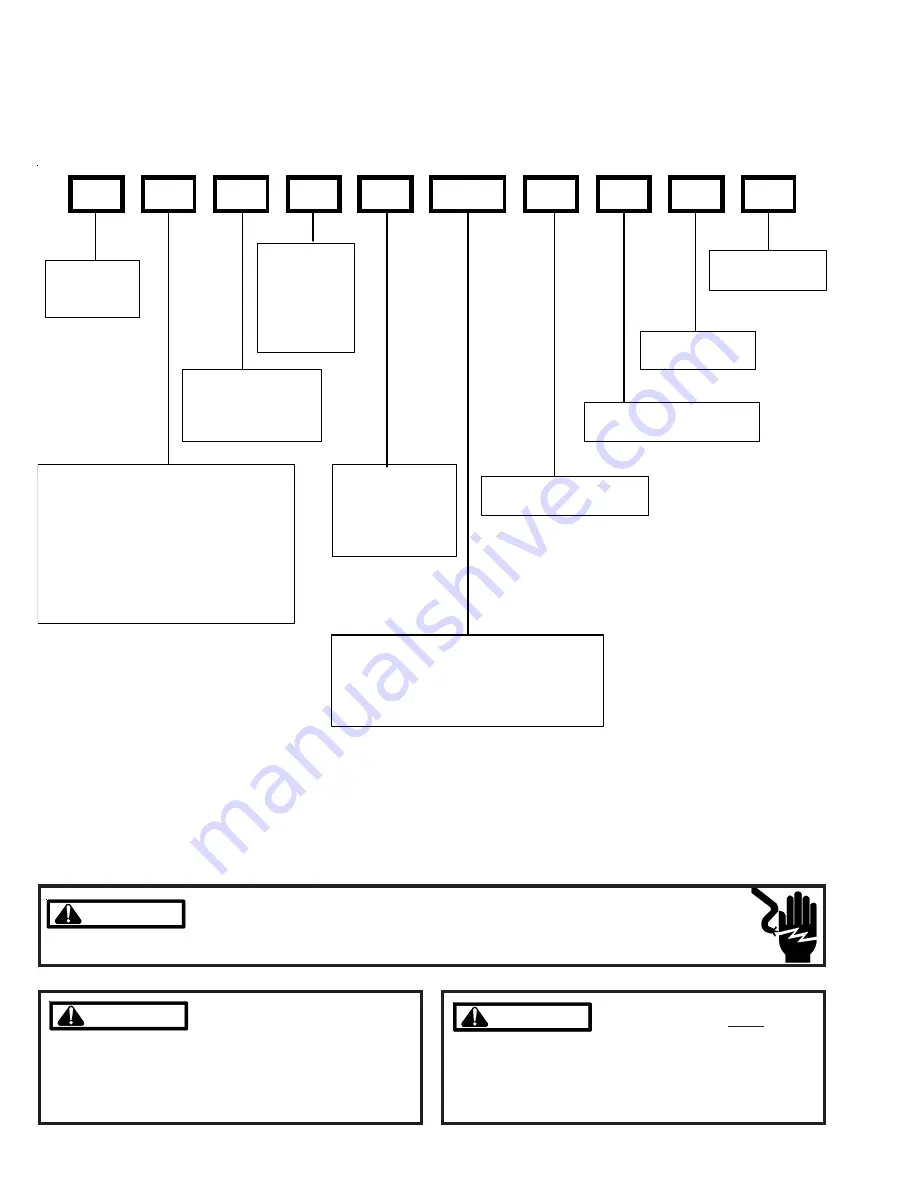

PRODUCT IDENTIFICATION

2

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

WARNING

WARNING

HIGH VOLTAGE!

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

Installation and repair of this unit

should be performed ONLY by in-

dividuals meeting (at a minimum)

the requirements of an "entry level technician", as speci-

fied by the Air-Conditioning, Heating, and Refrigeration

Institute (AHRI). Attempting to install or repair this unit

without such background may result in product damage,

personal injury or death.

Goodman will not be responsible

for any injury or property damage

arising from improper service or service procedures. If

you install or perform service on this unit, you assume

responsibility for any personal injury or property damage

which may result. Many jurisdictions require a license to

install or service heating and air conditioning equipment.

WARNING

WARNING

WARNING

WARNING

All Airhandlers use DIRECT DRIVE MOTORS. Power supply is AC 208-230v, 60 hz, 1 phase.

A

V

P

T

C

1830

1

4

A

A

PRODUCT

TYPE:

A: Air Handler

CABINET FINISH:

U: Unpainted

P: Painted

N: Uncased

EXPANSION

DEVICE:

F: Flowrater

T: TXV

(Expansion

Device)

MAJOR

REVISION*

MINOR

REVISION*

ELECTRICAL:

1: 208-230V/1ph/60Hz

APPLICATION

C: Ceiling Mount PSC Motor

D: Downflow PSC Motor

E: Multi-Position Varible Speed Motor

R: Multi-Position PSC Motor

S: Energy-Efficient Motor:

Multi-Position PSC Motor

T: Coated Coils

V: Variable Speed ECM Motor

REFRIGERANT CHARGE:

4: R-410A

NOMINAL CAPACITY RANGE:

Multi-Position & Downflow Applications

1830: 1 1/2 - 2 1/2 Tons

3137: 2 1/2 - 3 Tons

4260: 3 1/2 - 5 Tons

EXPANSION

DEVICE:

C: 4-Wire

Communicating

Ready