32

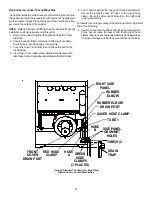

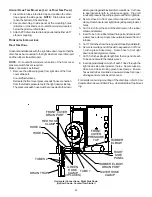

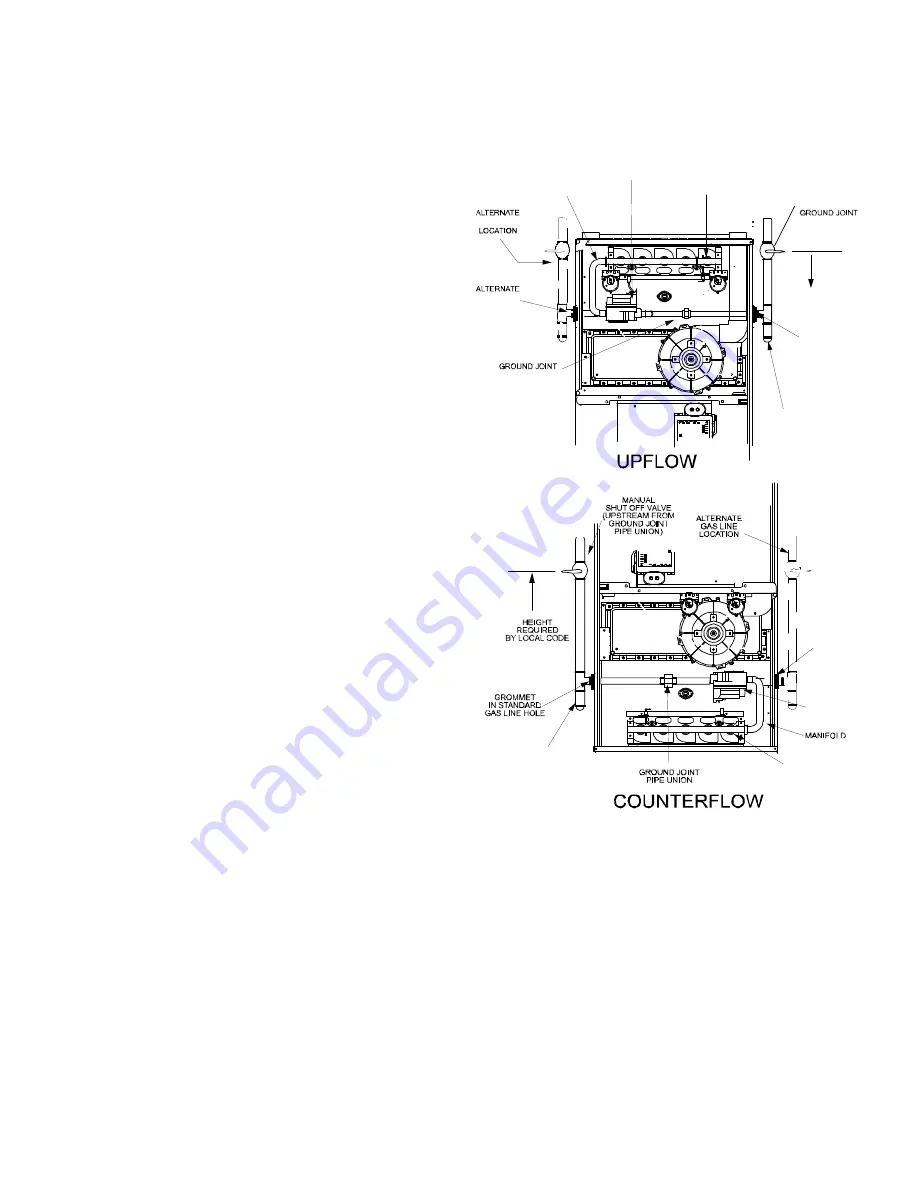

The following stipulations apply when connecting gas piping. Re-

fer to

Gas Piping Connections

figure for typical gas line connec-

tions to the furnace.

•

Gas piping must be supported external to the furnace

cabinet so that the weight of the gas line does not distort

the burner rack, manifold or gas valve.

•

Use black iron or steel pipe and fittings for building piping.

Where possible, use new pipe that is properly chamfered,

reamed, and free of burrs and chips. If old pipe is used, be

sure it is clean and free of rust, scale, burrs, chips, and old

pipe joint compound.

•

Use pipe joint compound on male threads ONLY. Always

use pipe joint compound (pipe dope) that is APPROVED

FOR ALL GASSES. DO NOT apply compound to the first

two threads.

•

Use ground joint unions.

•

Install a drip leg to trap dirt and moisture before it can enter

the gas valve. The drip leg must be a minimum of three

inches long.

•

Install a 1/8" NPT pipe plug fitting, accessible for test gage

connection, immediately upstream of the gas supply

connection to the furnace.

•

Always use a back-up wrench when making the connection

to the gas valve to keep it from turning. The orientation of

the gas valve on the manifold must be maintained as shipped

from the factory. Maximum torque for the gas valve

connection is 375 in-lbs; excessive over-tightening may

damage the gas valve.

•

Install a manual shutoff valve between the gas meter and

unit within six feet of the unit. If a union is installed, the

union must be downstream of the manual shutoff valve,

between the shutoff valve and the furnace.

•

Tighten all joints securely.

•

Connect the furnace to the building piping by one of the

following methods:

–

Rigid metallic pipe and fittings.

–

Semi-rigid metallic tubing and metallic fittings.

Aluminum alloy tubing must not be used in exterior

locations. In order to seal the grommet cabinet

penetration, rigid pipe must be used to reach the outside

of the cabinet. A semi-rigid connector to the gas piping

may be used from there.

•

Use listed gas appliance connectors in accordance with

their instructions. Connectors must be fully in the same

room as the furnace.

•

Protect connectors and semirigid tubing against physical

and thermal damage when installed. Ensure aluminum-

alloy tubing and connectors are coated to protect against

external corrosion when in contact with masonry, plaster,

or insulation, or subjected to repeated wetting by liquids

such as water (except rain water), detergents, or sewage.

MANUAL

SHUT OFF VALVE

(UPSTREAM FROM

PIPE UNION)

GROMMET

IN STANDARD

GAS LINE HOLE

GAS LINE

PLUG IN

GAS LINE

HOLE

HEIGHT REQUIRED

BY LOCAL CODE

PIPE UNION

DRIP LEG

MANIFOLD

BURNERS

GAS VALVE

PLUG IN

ALTER NATE

GAS LINE

HOLE

DRIP LEG

BURNERS

GAS VALVE