33

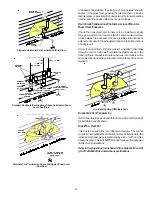

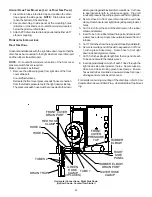

HORIZONTAL [UPFLOW MODEL]

MANUAL SHUT-OFF VALVE

(UPSTREAM FROM GROUND

JOINT PIPE UNION)

DRIP LEG

GROMMET IN STANDARD

GAS LINE HOLE

DRAIN TRAP

ALTERNATE GAS

LINE LO CATION

MANIFOLD

PLUG IN ALTERNATE

GAS LINE HOLE

GAS VALVE

GROUND JOINT

PIPE UNION

BURNERS

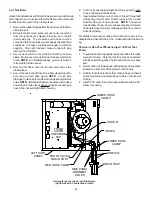

GAS VALVE

BURNERS

MANIFOLD

DRAIN TRAP

ALTERNATE GAS

LINE LOCATION

PLUG IN ALTERNATE

GAS LINE HOLE

HORIZONTAL[COUNTERFLOW]

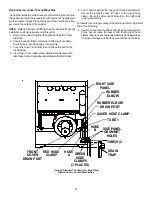

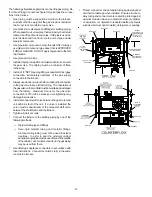

Gas Piping Connections

D

IRECT

/S

TANDARD

I

NLET

P

IPING

E

DGES

OF

SHEET

METAL

HOLES

MAY

BE

SHARP

.

U

SE

GLOVES

AS

A

PRECAUTION

WHEN

REMOVING

HOLE

PLUGS

.

WARNING

When gas piping enters

directly

to the gas valve through the

stan-

dard

inlet hole, the installer must supply straight pipe with a ground

joint union to reach the exterior of the furnace. The rigid pipe must

be long enough to reach the outside of the cabinet to seal the

grommet cabinet penetration. A semi-rigid connector to the gas

piping can be used outside the cabinet per local codes.

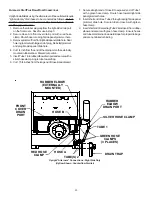

I

NDIRECT

/A

LTERNATE

I

NLET

P

IPING

When gas piping enters

indirectly

to the gas valve through the

alternate

gas inlet hole the following fittings (starting from the gas

valve) to reach the outside of the cabinet must be supplied:

•

Coupling.

•

90 degree elbow.

•

2 inch close nipple.

•

90 degree elbow.

•

Straight pipe, with a ground joint union, to reach the exterior

of the furnace. The rigid pipe must be long enough to reach

the outside of the cabinet so as to seal the grommet cabinet

penetration. A semi-rigid connector to the gas piping can

be used outside the cabinet per local codes.

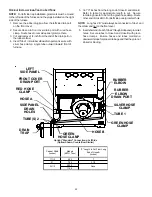

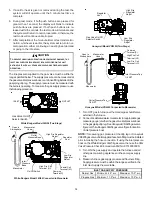

G

AS

P

IPING

C

HECKS

Before placing unit in operation, leak test the unit and gas connec-

tions.

T

O

AVOID

THE

POSSIBILITY

OF

EXPLOSION

OR

FIRE

,

NEVER

USE

A

MATCH

OR

OPEN

FLAME

TO

TEST

FOR

LEAKS

.

WARNING

Check for leaks using an approved chloride-free soap and water

solution, an electronic combustible gas detector, or other approved

testing methods.

NOTE:

Never exceed specified pressures for testing. Higher

pressure may damage the gas valve and cause subsequent

overfiring, resulting in heat exchanger failure.

Disconnect this unit and shutoff valve from the gas supply piping

system before pressure testing the supply piping system with

pressures in excess of 1/2 psig (3.48 kPa).

Isolate this unit from the gas supply piping system by closing its

external manual gas shutoff valve before pressure testing supply

piping system with test pressures equal to or less than 1/2 psig

(3.48 kPA).