40

•

Drainage system. Check for blockage and/or leakage. Check hose connections at and internal to furnace.

•

Wiring. Check electrical connections for tightness and/or corrosion. Check wires for damage.

•

Filters.

F

ILTERS

F

ILTER

M

AINTENANCE

Improper filter maintenance is the most com-

mon cause of inadequate heating or cooling

performance. Filters should be cleaned (per-

manent) or replaced (disposable) every two

months or as required. When replacing a fil-

ter, it must be replaced with a filter of the

same type and size.

F

ILTER

R

EMOVAL

Depending on the installation, differing filter

arrangements can be applied. Filters can be

installed in either the central return register

or a side panel external filter rack (upflow only).

A media air filter or electronic air cleaner can

be used as an alternate filter. Follow the filter

sizes given in the Recommended Minimum Fil-

ter size table to ensure proper unit perfor-

mance.

To remove filters from an external filter rack in an upright upflow installation, follow the directions provided with external filter rack

kit.

H

ORIZONTAL

U

NIT

F

ILTER

R

EMOVAL

Filters in horizontal installations are located in the central return register or the ductwork near the furnace.

To remove:

1. Turn OFF electrical power to furnace.

2. Remove filter(s) from the central return register or ductwork.

3. Replace filter(s) by reversing the procedure for removal.

4. Turn ON electrical power to furnace.

M

EDIA

A

IR

F

ILTER

OR

E

LECTRONIC

A

IR

C

LEANER

R

EMOVAL

Follow the manufacturer’s directions for service.

B

URNERS

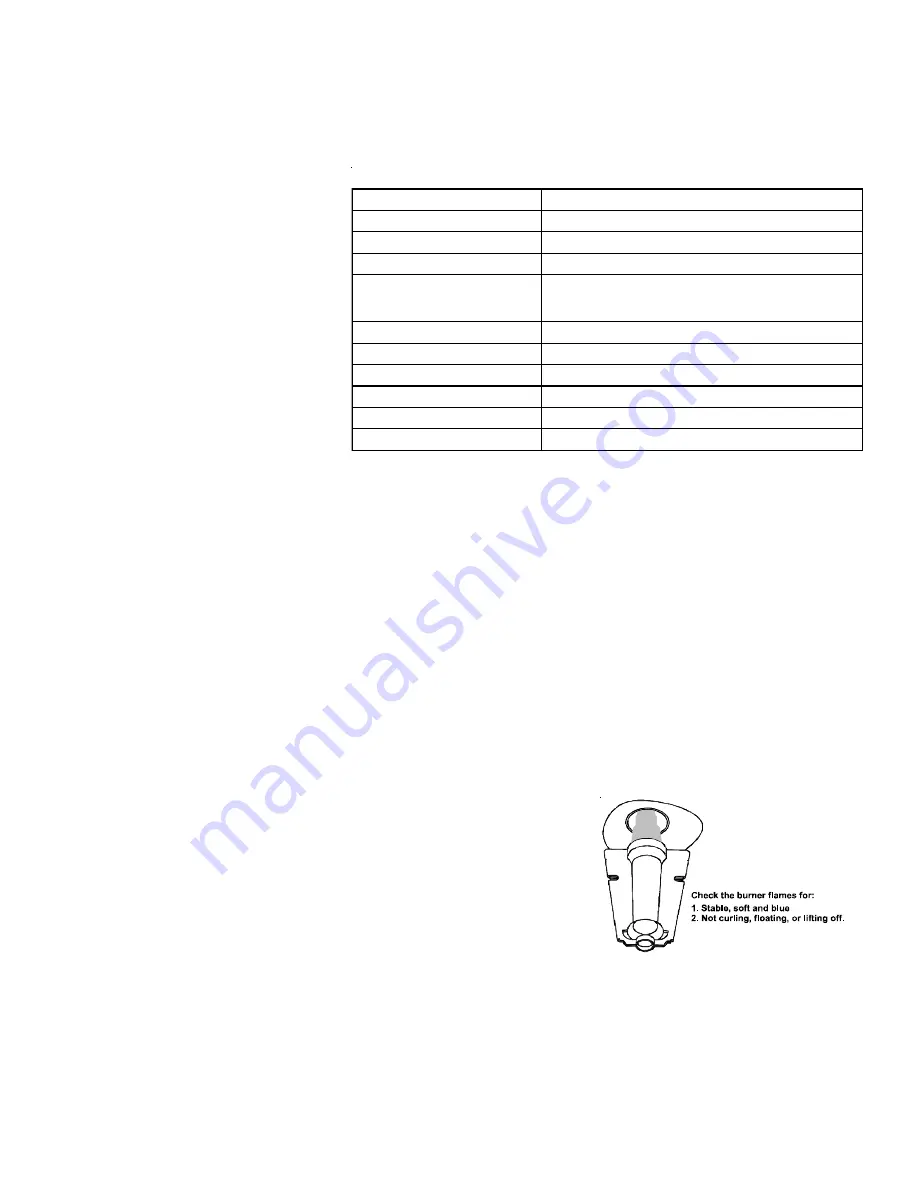

Visually inspect the burner flames periodically during the heating season. Turn on the

furnace at the thermostat and allow several minutes for flames to stabilize, since any

dislodged dust will alter the flames normal appearance. Flames should be stable, quiet,

soft, and blue (dust may cause orange tips but they must not be yellow). They should

extend directly outward from the burners without curling, floating, or lifting off. Flames

must not impinge on the sides of the heat exchanger firing tubes.

Burner Flame

Figure 43

DIAGNOSTIC CODES

1 flash, then pause

System lockout

2 flashes, then pause

Pressure switch stuck closed

3 flashes, then pause

Pressure switch stuck open

4 flashes, then pause

Open limit switch

5 flashes, then pause

Flame has been sensed when no flame

should be present (no call for heat)

6 flashes, then pause

Open rollout switch / open control board fuse

7 flashes, then pause

Low flame sense signal

8 flashes, then pause

Igniter relay fault

Continuous flashing

115 Volt AC power reversed

OFF

Control failure

ON

Normal operation

The LED will also flash once at power-up.