2

www.goodmanmfg.com

SS-GCEC96

SS-GCEC96

www.goodmanmfg.com

3

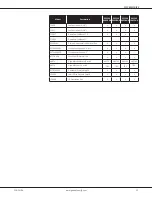

Product Specifications

GCEC96

0403BNA

GCEC96

0603BNA

GCEC96

0803BNA

GCEC96

1005CNA

Heating Data

High Fire Input¹

40,000

60,000

80,000

100,000

High Fire Output¹

38,400

57,600

76,800

96,000

Low-Fire Input¹

28,000

42,000

56,000

70,000

Low-Fire Output¹

26,880

40,320

53,760

67,200

AFUE²

96

96

96

96

Temp. Rise Range (°F)

20 - 50

20 - 50

35 - 65

35 - 65

Vent Diameter³

2" - 3"

2" - 3"

2" - 3"

2" - 3"

No. of Burners

2

3

4

5

Circulator Blower

Available AC @ 0.5" ESP

1.5 - 3

1.5 - 3

1.5 - 3

3 - 5

Size (D x W)

10" x 8"

11" x 8"

11" x 8"

11" x 10"

Horsepower @ 1075 RPM

1/2

1/2

1/2

1

Speed

5

5

5

5

Electrical Data

Min. Circuit Ampacity⁴

8

8

8

13.3

Max. Overcurrent (amps)⁵

15

15

15

15

Shipping Weight (lbs)

112

115

118

140

¹

Natural Gas BTU/h

² DOE AFUE based upon Isolated Combustion System (ICS)

³ Installer must supply one or two PVC pipes: one for combustion air (optional) and one for the flue outlet (required). Vent pipe must be either 2” or 3” in diameter, depending upon

furnace input, number of elbows, length of run and installation (1 or 2 pipes). The optional Combustion Air Pipe is dependent on installation/code requirements and must be 2” or

3” diameter PVC.

⁴

Minimum Circuit Ampacity = (1.25 x Circulator Blower Amps) + ID Blower amps. Wire size should be determined in accordance with National Electrical Codes. Extensive wire runs

will require larger wire sizes.

⁵ Maximum Overcurrent Protection Device refers to maximum recommended fuse or circuit breaker size. May use fuses or HACR-type circuit breakers of the same size as noted.

Notes

•

All furnaces are manufactured for use on 115 VAC, 60 Hz, single-phase electrical supply.

•

Gas Service Connection ½” FPT

•

Important: Size fuses and wires properly and make electrical connections in accordance with the National Electrical Code and/or all existing local codes.

•

For bottom return: Failure to unfold flanges may reduce airflow by up to 18%. This could result in performance and noise issues.

•

For servicing or cleaning, a 24” front clearance is required. Unit connections (electrical, flue and drain) may necessitate greater clearances than the minimum clearances listed

above. In all cases, accessibility clearance must take precedence over clearances from the enclosure where accessibility clearances are greater.

![Roberts Gorden Combat UHD[S] 150-400 Specifications preview](http://thumbs.mh-extra.com/thumbs/roberts-gorden/combat-uhd-s-150-400/combat-uhd-s-150-400_specifications_1469644-1.webp)