19

1. Remove the rubber plug from the front cover drain port (right

or left side, depending on the intended drain trap mounting).

2. Secure Hose A to front cover drain port with a red hose

clamp. Route hose to rear side panel grommet hole.

NOTE: For left side drainage, grommets will have to be relocated

to left side panel.

DRAIN

TRAP

FRONT COVER

DRAIN PORT

TUBE(S) 2

GREEN

HOSE

CLAMPS

(3 PLACES)

RIGHT SIDE

PANEL

RUBBER ELBOW

DRAIN PORT

TUBE 1

SIDE PANEL

GROMMET

HOLES

HOSE

B

HOSE

A

RUBBER

ELBOW

RED HOSE

CLAMP

SILVER HOSE CLAMP

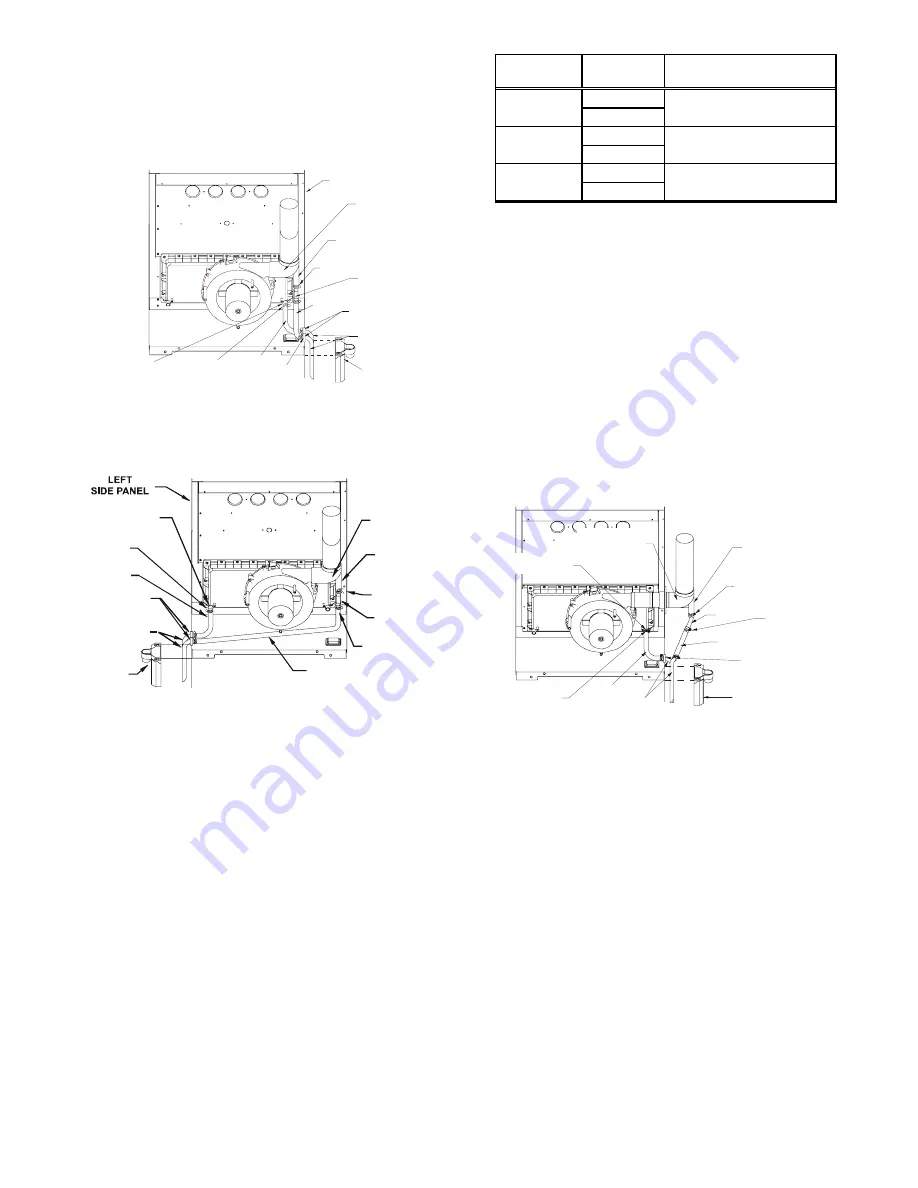

Upright “Standard” Connections - Right Side

(Upflow Shown, Counterflow Similar)

FRONT COVER

DRAIN PORT

HOSE A

SIDE PANEL

DRAIN

HOLES

TUBE(S) 2

DRAIN

TRAP

GREEN HOSE

CLAMPS

(3 PLACES)

TUBE 1

RUBBER

ELBOW

HOSE B

RUBBER

ELBOW

DRAIN PORT

RED HOSE

CLAMP

SILVER HOSE

CLAMP

Upright “Standard” Connections - Left Side

(Upflow Shown, Counterflow Similar)

3. Cut and remove 1/4 inch from the end of the drain port on

the rubber elbow.

4. Insert Tube 1 into rubber elbow drain port and secure with

silver hose clamp. Angle tube outward toward front of

furnace.

5.

Right

side drains

Cut 17 3/4 inches from the long end (end opposite the

bend) of Hose B, discarding the 17 3/4 inch piece and

saving the part with the bend. Secure the remaining hose

to Tube 1 with a green hose clamp. Route the other end of

Hose B to front right side panel grommet hole.

Left

side drains

Cut “X” inches from the long end of Hose B and discard.

Refer to table for appropriate length to cut. Secure remaining

hose to Tube 1 with a green hose clamp. Route other end

of Hose B to front left side panel grommet hole.

Cabinet Width

(inches)

Models

(kBTU_Tons)

"X" Length to Cut From Long

End of Hose B

045__30

070__30

070__40

090__40

090__50

115__50

24 1/2

None

17 1/2

21

7 inc hes

3 1/2 inches

6. Insert short end of each Tube 2 through side panel grommet

holes. Secure tubes to Hose A and Hose B with green

hose clamps. Ensure hoses and tubes maintain a

downward slope for proper drainage and that they are not

kinked or binding.

For details concerning mounting of the drain trap, refer to

Section

X, Condensate Drain Lines and Drain Trap - Upright Drain Trap

Mounting.

A

LTERNATE

V

ENT

/F

LUE

D

RAIN

H

OSE

C

ONNECTIONS

Upright installations using the

alternate

vent/flue outlet will require

“right-side only” drain hoses to be connected as follows. Refer to

Section IX, Vent/Flue Pipe and Combustion Air Pipe

for details on

alternate vent/flue pipe connection.

1. Remove the rubber plug from the front cover right-side drain

port. Save for use in step 3.

2. Secure Hose A to front cover drain port with a red hose

clamp. Route hose to rear right side panel grommet hole.

RUBBER ELBOW

(EXTERNALLY

MOUNTED)

TUBE 1

GREEN HOSE

CLAMPS

(3 PLACES)

HOSE B

TUBE(S) 2

DRAIN TRAP

SIDE PANEL

GROMMET

HOLES

HOSE A

FRONT COVER

DRAIN PORT

RUBBER

ELBOW

DRAIN PORT

RED HOSE

CLAMP

SILVER HOSE CLAMP

Upright “Alternate” Connections - Right Side Only

(Upflow Shown, Counterflow Similar)

3. Remove grommet from front right-side panel drain hole.

Seal hole in grommet with large end of plug. Reinstall

grommet and plug into side panel drain hole.

4. Cut 1/4 inch from the end of the drain port on the externally

mounted rubber elbow. Discard cut portion.

5. Insert Tube 1 into rubber elbow drain port and secure with

a silver hose clamp. Angle tube outward toward front of

furnace.

6. Cut 17 7/8 inches from the long end of Hose B and discard.

7. Secure remaining end of Hose B to exposed end of Tube 1

with a green hose clamp. Route hose toward right side

panel grommet holes.

8. Insert short end of one Tube 2 through rear right side panel

grommet drain hole. Secure tube to Hose A with a green

hose clamp.

9. Insert short end of remaining Tube 2 into Hose B from

rubber elbow and secure with green hose clamp. Ensure

hoses and tubes maintain a downward slope for proper

drainage and are not kinked or binding.

For details concerning mounting of the drain trap, refer to the fol-

lowing section.