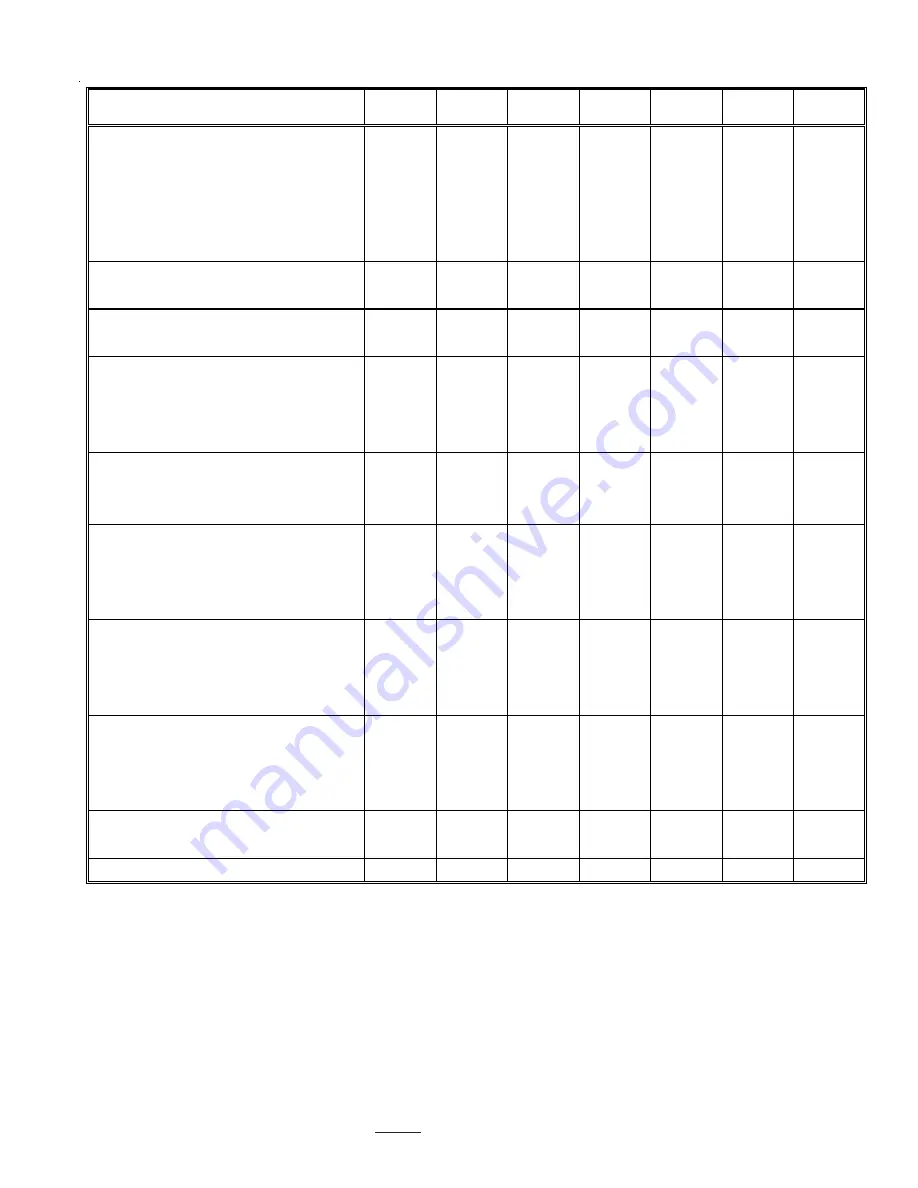

FURNACE SPECIFICATIONS

11

1. These furnaces are manufactured for natural gas operation. Optional kits are available for conversion to propane operation.

2. For elevations above 2000 feet the rating should be reduced by 4% for each 1000 feet above sea level. The furnace must not be derated, orifice changes should only

be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufacturers method or in accordance with the "A.S.H.R.A.E.

GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal

to or less than the heating capacity. Output based on D.O.E. test procedures.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

Unit specifications are subject to change without notice.

ALWAYS

refer to the units serial plate for the most up-to-date general and electrical information.

(1)

Wire size should be determined in accordance with National Electrical Codes. Extensive wire runs will require larger wire sizes.

(2)

Maximum Overcurrent Protection Device: May use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

(3)

Off Heating - this fan delay timing is adjustable (100 and 150 seconds). Furnaces are shipped with 150 second off delay.

(4)

See Installation Instructions for appropriate vent diameter, length and number of elbows.

(5)

See Installation Instructions for appropriate combustion air pipe diameter, length and number of elbows.

NOTE: This data is provided as a guide, it is important to electrically connect the unit and properly size fuses/circuit breakers and wires in

accordance with all national and/or local electrical codes. Use copper wire only.

GMH95

M ODEL

GM H95

0453BXA*

GMH95

0703BXA*

GMH95

0704CXA*

GMH95

0904CXA*

GM H95

0905CXA*

GM H95

0905DXA*

GMH95

1155DXA*

Btuh

Input (U S)

46,000

69,000

69,000

92,000

92,000

92,000

115,000

Output (U S)

44,400

66,400

66,900

89,000

88,400

88,400

110,500

Input (C AN )

46,000

69,000

69,000

92,000

92,000

92,000

115,000

Output (C AN )

44,400

66,400

66,900

89,000

89,400

89,400

110,500

A.F.U .E.

95.0%

95.0%

95.0%

95.0%

95.0%

95.0%

95.0%

R ated External Static (" w .c.)

.20 - .50

.20 - .50

.20 - .50

.20 - .50

.20 - .50

.20 - .50

.20 - .50

Tem perature R is e (°F)

35 - 65

30 - 60

35 - 65

30 - 60

30 - 60

35 - 65

35 - 65

ID Blow er Pres s ure Sw itch Trip Point (" w .c.)

-1.10

-0.95

-1.10

-1.20

-1.35

-1.10

-1.10

Front C over Pres s ure Sw itch Trip Point (" w .c.)

-0.37

-0.37

-0.37

-0.60

-0.10

-0.37

-0.60

Blow er Wheel (D " x W")

10 x 8

10 x 8

10 x 10

10 x 10

11 x 10

11 x 10

11 x 10

Blow er H ors epow er

1/3

1/3

1/2

1/2

3/4

3/4

3/4

Blow er Speeds

4

4

4

4

4

4

4

Max C FM @ 0.5 E.S.P.

1200

1200

1600

1600

1800

2000

2000

Pow er Supply

115-60-1

115-60-1

115-60-1

115-60-1

115-60-1

115-60-1

115-60-1

Minim um C ircuit Am pacity (MC A)

(1)

9.4

9.4

13.8

13.8

13.2

13.2

13.2

Maxim um Overcurrent D evice

(2)

15.0

15.0

15.0

15.0

15.0

15.0

15.0

Trans form er (VA)

40

40

40

40

40

40

40

Prim ary Lim it Setting (°F)

150

160

160

150

130

160

160

Auxiliary Lim it Setting (°F)

150

150

150

150

120

150

160

R ollout Lim it Setting (°F)

200

200

200

200

210

200

200

Fan D elay On H eating

30 s ecs .

30 s ecs .

30 s ecs .

30 s ecs .

30 s ecs .

30 s ecs .

30 s ecs .

Off H eating

(3)

150 s ecs .

150 s ecs .

150 s ecs .

150 s ecs .

150 s ecs .

150 s ecs .

150 s ecs .

Fan D elay On C ooling

6 s ec.

6 s ec.

6 s ec.

6 s ec.

6 s ec.

6 s ec.

6 s ec.

Off C ooling

45 s ecs .

45 s ecs .

45 s ecs .

45 s ecs .

45 s ecs .

45 s ecs .

45 s ecs .

Gas Supply Pres s ure (N atural/Propane) ("w .c.)

7 / 11

7 / 11

7 / 11

7 / 11

7 / 11

7 / 11

7 / 11

Manifold Pres s ure (N atural/Propane) ("w .c.)

3.5 / 10

3.5 / 10

3.5 / 10

3.5 / 10

3.5 / 10

3.5 / 10

3.5 / 10

Orifice Size (N atural/Propane)

43 / 55

43 / 55

43 / 55

43 / 55

43 / 55

43 / 55

43 / 55

N um ber of Burners

2

3

3

4

4

4

5

Vent C onnector D iam eter (inches )

(4)

2

2

2

2

2

2

2

C om bus tion Air C onnector D iam eter (inches )

(5)

2

2

2

2

2

2

2

Shipping Weight (lbs .)

132

135

136

158

172

172

175