14

Check both manifold pressure (using the 1/8" NPT tap located on the gas valve) and service pressure (using the 1/8" NPT

tap as shown in the drawing above).

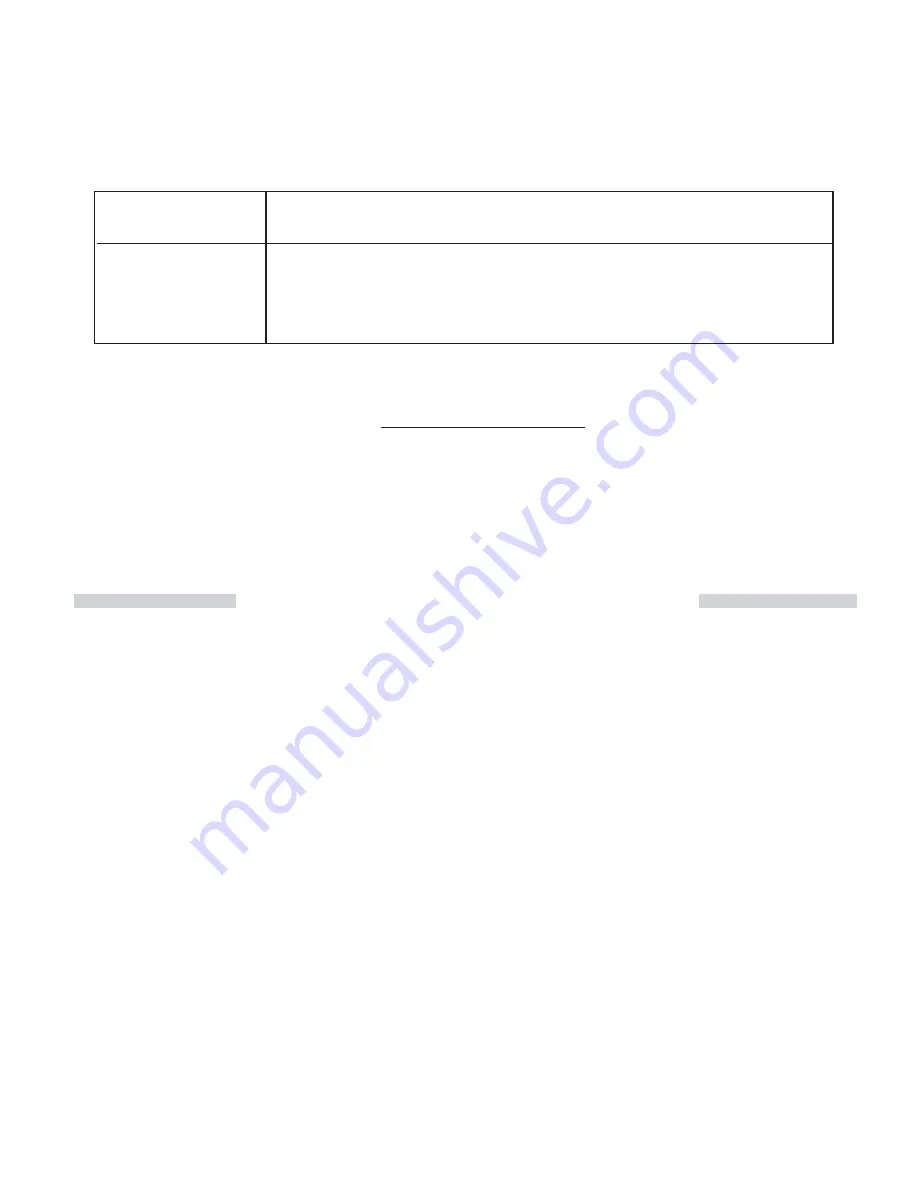

GAS PIPE CAPACITY TABLE (CU. FT./HR)

Capacity of gas pipe of different diameters and length in cu. ft. per hr. with pressure drop of 0.3 in. and specific gravity of

0.60 (natural gas). NOTE :

COPPER TUBING MUST NOT BE USED FOR NATURAL GAS INSTALLATIONS.

Nominal Iron

Length of Pipe, Feet

Pipe Size, Inches

10

20

30

40

50

60

70

80

1/2

132

92

73

63

56

50

46

43

3/4

278

190

152

130

115

105

96

90

1

520

350

285

245

215

195

180

170

1 1/4

1050

730

590

500

440

400

370

350

1 1/2

1600

1100

890

760

670

610

560

530

After the length of pipe has been determined, select the pipe size which will provide the minimum cubic feet per hour required

for the gas input rating of the furnace using the formula :

Cu. Ft.Per Hr. Required =

Gas Input of Furnace(BTU/HR)

Heating Value of Gas (BTU/HR)

The gas input of the furnace is marked on the furnace rating plate. The heating calorific value of the gas (BTU/Ft

3

) may be

determined by consulting the local natural gas utility or the L.P. gas supplier.

If your local utility/ building codes permit the use of a flexible gas line ALWAYS USE A NEW LINE. DO NOT USE FLEXIBLE

GAS LINES WHICH HAVE PREVIOUSLY SERVICED ANOTHER APPLIANCE.

CIRCULATING SUPPLY AIR AND RETURN AIR.

The circulating air return may be taken from:

(1) outside the building (2) return ducts from several rooms (3) central return (4) any combination of the above.

Note:

When outside air is utilized, the system should be designed and adjusted such that the temperature of the air supply

to the furnace will not drop to below 50°F during the heating season.

When a combination of indoor and outside air is used (in conjunction with a mixing or diverting damper) the volume of air

must not be reduced.

Plenum chambers and air ducts must be installed in accordance with Standard for the Installation of Air Conditioning and

Ventilating Systems, NFPA No. 90A, or the Standard for the Installation of Warm Air Heating and Air Conditioning Systems,

NFPA No. 90B.

When the ducts are installed so that the supply ducts carry air circulated by the furnace to area outside the space containing

the furnace, the return air shall be handled by a duct or ducts sealed to the furnace casing and terminated outside the space

containing the furnace. If there is no complete return air duct system, the return air connection must be sealed to the furnace

casing and run full size to a location outside the utility room or space housing the furnace. The furnace must be installed

in a level and plumb position.

If installed in parallel with a cooling unit, the damper or other means used to control the flow of air must be adequate to prevent

Summary of Contents for GMN SERIES

Page 26: ...WIRINGDIAGRAM 26...