18

chilled air from entering the furnace, and if manually operated must be equipped with means to prevent operation of the other

unit unless the damper is in the full heat or cool position.

EXAMPLE :

Corrected input for a GMN100-4 installed at an elevation of 6,000 feet using Natural Gas with

a heating value of 1000

(BTUH) is =

Corrected Input (BTUH) = 100,000 - (6,000 x .04) x (100,000/ 1,000)

Corrected Input (BTUH) = 100,000 -(240 x 100)

Corrected Input (BTUH) = 100,000 - 24,000

Corrected Input (BTUH) = 76,000

Using the orifices shown in the table for 6000 feet elevation (#48). A meter time of 48.0 seconds is measured.

The actual firing rate of the furnace =

Input BTUH =

1,000 (Heating Value of Gas) x 3,600

48.0 Meter time for 1 cubic foot of gas)

Input BTUH =

3,600,000 / 48.0

Input BTUH =

75,000 BTUH

TIMING THE GAS METER

Use the following method to time determine the firing rate of the furnace. Location of inlet and manifold pressure taps are

shown in the “GAS SUPPLY AND PIPING” section of these instructions.

Before attempting any service or adjustments - Insure that Gas & Electrical Supplies are "OFF".

1.) Install a manometer graduated in tenths of an inch of water column on the inlet pressure tap.

2.) Remove plug at the “Manifold Pressure Tap” on the gas valve and install second manometer.

3.) Determine the size of the gas meter being used.

4.) Shut off all other gas appliances with the exception of pilot burners.

5.) Place the furnace into operation.

6.) Adjust inlet pressure to obtain a pressure range between 5" and 7" W.C.

7.) After 15 minutes of furnace operation, time meter with an accurate stop watch for 2 revolutions.

8.) Divide time obtained in step 7 by 2.

9.) Use the appropriate table or formula to determine firing input.

10.) If necessary, adjust manifold pressure at the gas valve by removing the regulator cap and turn adjustment screw

clockwise to obtain a higher pressure or counterclockwise to reduce manifold pressure. Manifold pressure must be within

a range of 3.2" to 3.8" W.C. Inability to obtain the correct firing rate will result in the need to re-orifice. If manifold pressure

or re-orificing is necessary repeat steps 4 through 10 after the furnace has been allowed to cool down for approximately 10

- 15 minutes.

11.) Turn off gas and electric supply, remove manometers and replace any plug removed in steps 1 and 2, using a joint

compound resistant to L.P. Gas.

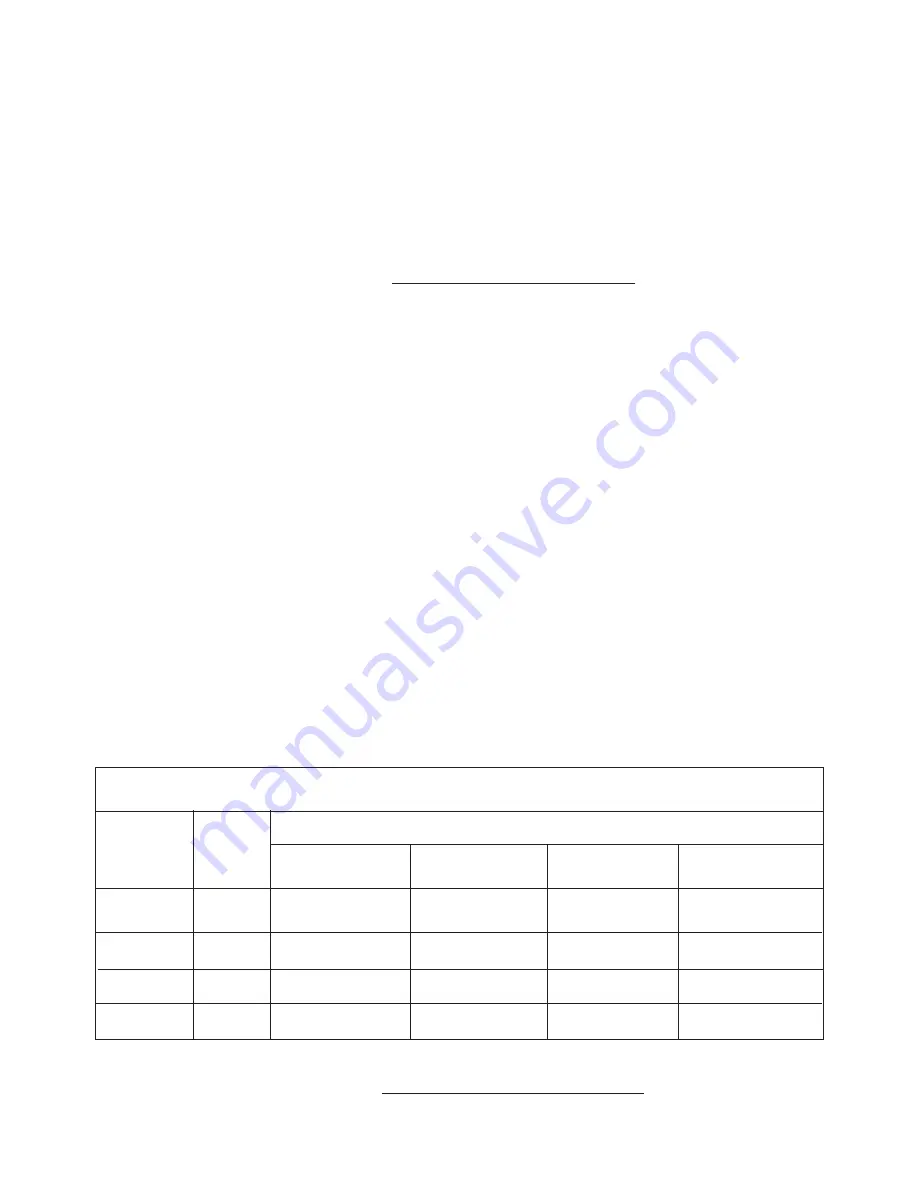

METER TIME IN MINUTES AND SECOND FOR NORMAL INPUT RATING

OF FURNACES EQUIPPED FOR NATURAL GAS

.

0-2000 FEET ALTITUDE

Nameplate

Meter

Heating Value of Gas BTU per Cu.Ft.

Input

Size

900

1000

1040

1100

BTU/Hr.

Cu.Ft.

Min.

Sec.

Min.

Sec.

Min.

Sec.

Min.

Sec.

60,000

1

0

54

1

00

1

03

1

06

10

9

00

10

00

10

24

11

00

80,000

1

0

41

0

45

0

47

0

50

10

6

45

7

30

7

48

8

15

100,000

1

0

32

0

36

0

37

0

40

10

5

24

6

00

6

14

6

36

120,000

1

0

27

0

30

0

31

0

33

10

4

30

5

00

5

12

5

30

Input BTU/HR = Heating Value of Gas (BTU/FT3) x 3600

Time in Second (for 1 cu.ft.) of Gas

Summary of Contents for GMN SERIES

Page 26: ...WIRINGDIAGRAM 26...