IO-151

17

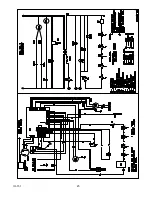

INTEGRATED FAN / IGNITION CONTROL

This furnace is equipped with a combination ignition module and fan control. An electronic device

ignites the burners upon a call for heat. It also controls the venter blower and the various speed

selections of the circulating air blower. This control is located in the circulating air blower

compartment. Upon a demand for heat the venter is energized. After a short purge, the electronic

ignition device is energized. The burners are ignited after a short delay and the burner flame is

proven. The circulating air blower is energized approximately thirty (30) seconds after the burners

are ignited. The circulating air blower off time is field selectable. THIS CONTROL IS NOT FIELD

SERVICEABLE.

CIRCULATING AIR FILTERS

One of the most common causes of problems in a forced air heating system is blocked or dirty

filters. Circulating air filters must be inspected monthly for dirt accumulation and replaced if

necessary. Failure to maintain clean filters can cause premature heat exchanger failure. A new

home may require more frequent replacement until all construction dust and dirt is removed.

Circulating air filters are to be installed external to the furnace cabinet.

CAUTION

Before performing any service on this furnace, including checking or replacing circulating air filters

- disconnect main power.

DO NOT

operate the furnace for extended periods of time without filters in place. Dust and dirt in

the air will restrict the air movement over the secondary coil causing nuisance cycling of safety

controls which may result in a “no heat condition.”

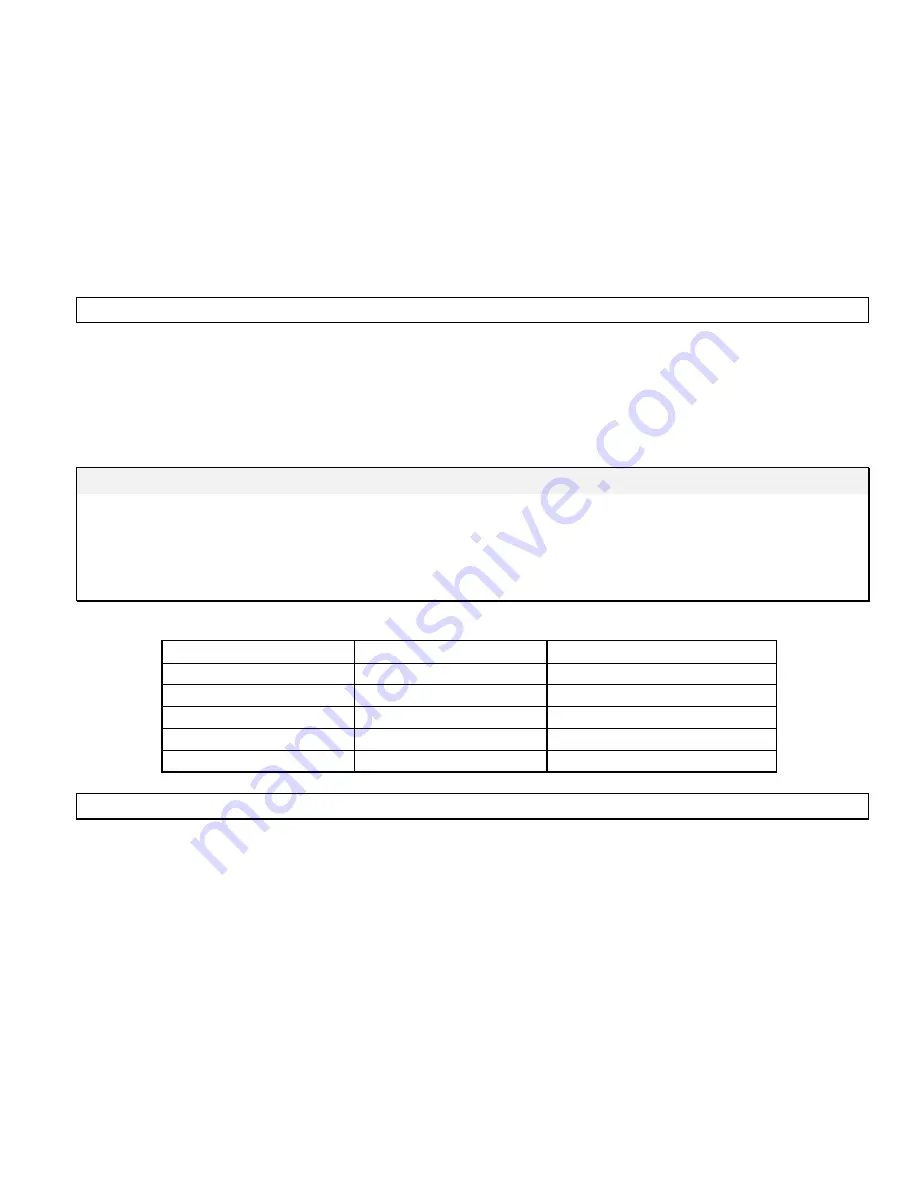

MINIMUM FILTER SIZES

INPUT BTUH

FILTER SIZE

TYPE

40,000

320 / 160 IN.

2

DISPOS. / PERMAN.

60,000

480 / 240 IN.

2

DISPOS. / PERMAN.

80,000

640 / 320 IN.

2

DISPOS. / PERMAN.

100,000

727 / 363 IN.

2

DISPOS. / PERMAN.

120,000

960 / 480 IN.

2

DISPOS. / PERMAN.

TEMPERATURE RISE

The temperature difference between the outlet air and the inlet air of the furnace is known as the

temperature rise. This furnace is designed to operate within the temperature rise displayed on the

furnace series and rating plate. To ensure satisfactory performance, the temperature rise of the

furnace must be measured and adjusted if necessary. Use the following procedure to measure

and adjust the temperature rise;

•

Prior to starting the furnace visually inspect all joints and seams in the supply and return air

ducts for leaks. Repair them if necessary.

•

Adjust the room thermostat to obtain constant operation.

•

Allow the furnace to operate for at least fifteen (15) minutes.

•

With an accurate thermometer measure the temperature at the return air grille. If a

combination indoor / outdoor system is used, the temperature must be measured downstream

of the connection.