22

*

*

*

*

*

*

*

*

*

STANDARD

JUNCTION BOX

LOCATION

ALTERNATE

JUNCTION BOX

LOCATION

Junction Box Relocation

WARNING

T

O AVOID THE RISK OF INJURY, ELECTRICAL SHOCK OR DEATH, THE FURNACE

MUST BE ELECTRICALLY GROUNDED IN ACCORDANCE WITH LOCAL CODES OR,

IN THEIR ABSENCE, WITH THE LATEST EDITION OF THE

N

ATIONAL

E

LECTRIC

C

ODE.

To ensure proper unit grounding, the ground wire should run from

the furnace ground screw located inside the furnace junction box

all the way back to the electrical panel.

NOTE:

Do not use gas

piping as an electrical ground. To confirm proper unit grounding,

turn off the electrical power and perform the following check.

1.

Measure resistance between the neutral (white) connection

and one of the burners.

2.

Resistance should measure 10 ohms or less.

This furnace is equipped with a blower door interlock switch which

interrupts unit voltage when the blower door is opened for servic-

ing. Do not defeat this switch.

24 V

OLT

T

HERMOSTAT

W

IRING

NOTE:

Wire routing must not interfere with circulator blower

operation, filter removal, or routine maintenance.

Low voltage connections can be made through either the right or

left side panel. Thermostat wiring entrance holes are located in the

blower compartment. Wire routing must not to interfere with circu-

lator blower operation, filter removal, or routine maintenance. Re-

fer to the following figure for thermostat connections to the inte-

grated control module terminal strip.

W

W

W

Y

Y

Y

C

C

R

R

R

G

G

W

Y

C

R

G

HEATING

ROOM

THERMOSTAT

HEATING AND

COOLING ROOM

THERMOSTAT

FURNACE

FURNACE

REMOTE

CONDENSING

UNIT

Thermostat Diagram

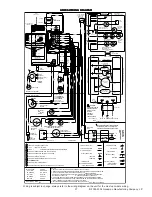

This furnace is equipped with a 40 VA transformer to facilitate use

with most cooling equipment. Consult the wiring diagram, located

on the blower compartment door, for further details of 115 Volt and

24 Volt wiring.

115 V

OLT

L

INE

C

ONNECTION

OF

A

CCESSORIES

(H

UMIDIFIER

AND

E

LECTRONIC

A

IR

C

LEANER

)

WARNING

T

O AVOID INJURY, ELECTRICAL SHOCK OR DEATH, DISCONNECT ELECTRICAL

POWER BEFORE SERVICING OR CHANGING ANY ELECTRICAL WIRING.

The furnace’s integrated control module is equipped with line volt-

age accessory terminals for controlling power to an optional field-

supplied humidifier and/or electronic air cleaner.

The accessory load specifications are as follows:

Humidifier

1.0 Amp maximum at 120 VAC

Electronic Air Cleaner

1.0 Amp maximum at 120 VAC

Turn OFF power to the furnace before installing any accessories.

Follow the humidifier or air cleaner manufacturers’ instructions for

locating, mounting, grounding, and controlling these accessories.

Accessory wiring connections are to be made through the 1/4"

quick connect terminals provided on the furnace integrated control

module. The humidifier and electronic air cleaner hot and neutral

terminals are identified as HUM and EAC. All field wiring must

conform to applicable codes. Connections should be made as

shown below.

ELECTRONIC

AIR CLEANER

HUMIDIFIER

OPTIONAL

ACCESSORIES

12 PIN

CONNECTOR

120 VAC

NEUTRAL

TERMINALS

HUM-N

EAC-N

HUM

-H

EAC

-H

120 VAC

HOT AND

PARK

TERMINALS

INTEGRATED

CONTROL

MODULE

Accessories Wiring

If it is necessary for the installer to supply additional line voltage

wiring to the inside of the furnace, the wiring must conform to all

local codes, and have a minimum temperature rating of 105°C. All

line voltage wire splices must be made inside the furnace junction

box.

The integrated control module humidifier terminals (HUM) are en-

ergized with 115 volts whenever the induced draft blower is ener-

gized. The integrated control module electronic air cleaner termi-

nals (EAC) are energized with 115 volts whenever the circulator

blower is energized.

24 V

OLT

H

UMIDIFIER

A 1/4” piggy back quick connect terminal on the pressure switch

provides 24VAC humidifier control. This terminal is powered any

time the pressure switch closes. To connect 24VAC HUM, connect

the

24VAC

line of the humidifier to the piggyback on the pressure

switch and the

COM

line of the humidifier to

C

on the control board

terminal strip (or to the

COM

side of the 24VAC transformer). Do

not connect 115V humidifier to these terminals.

XII. GAS SUPPLY AND PIPING

XII. GAS SUPPLY AND PIPING

XII. GAS SUPPLY AND PIPING

XII. GAS SUPPLY AND PIPING

XII. GAS SUPPLY AND PIPING

G

ENERAL

The furnace rating plate includes the approved furnace gas input

rating and gas types. The furnace must be equipped to operate on

the type of gas applied. This includes any conversion kits required

for alternate fuels and/or high altitude.

CAUTION

T

O PREVENT UNRELIABLE OPERATION OR EQUIPMENT DAMAGE, THE INLET

GAS SUPPLY PRESSURE MUST BE AS SPECIFIED ON THE UNIT RATING PLATE

WITH ALL OTHER HOUSEHOLD GAS FIRED APPLIANCES OPERATING.

Inlet gas supply pressures must be maintained within the ranges

specified below. The supply pressure must be constant and avail-

able with all other household gas fired appliances operating. The

Summary of Contents for GMS95

Page 34: ...34...