26

Room

Thermostat

Y2

Y

W

W2

R

G

C

Ylo

Y

W

W2

R

G

C

Ylo

Y

W

W2

R

G

C

Furnace 1

Furnace 2

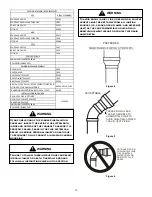

Figure 37

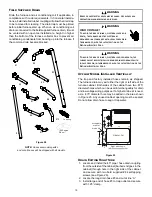

115 Volt Line Connection of Accessories

(Humidifier and Electronic Air Cleaner)

The furnace integrated control module is equipped with line

voltage accessory terminals for controlling power to an op

-

tional field-supplied humidifier and/or electronic air cleaner.

The accessory load specifications are noted in the chart

below:

Humidifier

1.0 Amp maximum at 120 VAC

Electronic Air Cleaner

1.0 Amp maximum at 120 VAC

Turn OFF power to the furnace before installing any acces-

sories. Follow the humidifier or air cleaner manufacturers’

instructions for locating, mounting, grounding, and controlling

these accessories. Accessory wiring connections are to be

made through the 1/4” quick connect terminals provided on

the furnace integrated control module. The humidifier and

electronic air cleaner hot terminals are identified as HUM

and EAC. The humidifier and electronic air cleaner neutral

terminals are identified as NEUTRAL. All field wiring must

conform to applicable codes. Connections should be made

as shown.

If it is necessary for the installer to supply additional line

voltage wiring to the inside of the furnace, the wiring must

conform to all local codes, and have a minimum temperature

rating of 105°C. All line voltage wire splices must be made

inside the furnace junction box.

The integrated control module humidifier terminal (HUM) is

energized with 115 volts whenever the induced draft blower

is energized. The integrated control module electronic air

cleaner terminal (EAC) is energized with 115 volts whenever

the circulator blower is energized. This terminal can also be

used to provide 115 volt power to a humidifier transformer.

The remaining primary transformer wire would be connected

to the Line N on the control board.

HIGH VOLTAGE !

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

SERVICING

OR

CHANGING

ANY

ELECTRICAL

WIRING

.

WARNING

Accessories - Accessories Wiring

Gas Supply and Piping

T

O

AVOID

POSSIBLE

UNSATISFACTORY

OPERATION

OF

EQUIPMENT

DAMAGE

DUE

TO

UNDERFIRING

OR

EQUIPMENT

,

USE

THE

PROPER

SIZE

OF

NATURAL

/

PROPANE

GAS

PIPING

NEEDED

WHEN

RUNNING

PIPE

FROM

THE

METER

/

TANK

TO

THE

FURNACE

.

WARNING

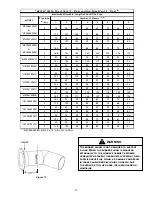

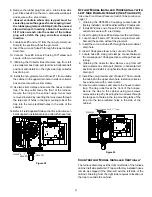

Natural Gas

Minimum: 4.5" w.c.

Maximum: 10.0" w.c.

Propane Gas

Minimum: 11.0" w.c. Maximum: 13.0" w.c.

INLET GAS SUPPLY PRESSURE

The furnace rating plate includes the approved furnace gas

input rating and gas types. The furnace must be equipped

to operate on the type of gas applied. This includes any con

-

version kits required for alternate fuels and/or high altitude.

Inlet gas supply pressures must be maintained within the

ranges specified in the adjacent table. The supply pressure

must be constant and available with all other household gas

fired appliances operating. The minimum gas supply pres

-

sure must be maintained to prevent unreliable ignition. The

maximum must not be exceeded to prevent unit overfiring.

High Altitude Derate

When this furnace is installed at high altitude, the appropriate

High Altitude orifice kit must be applied. This is required due

to the natural reduction in the density of both the gas fuel

and combustion air as altitude increases. The kit will provide

the proper design certified input rate within the specified

altitude range.