49

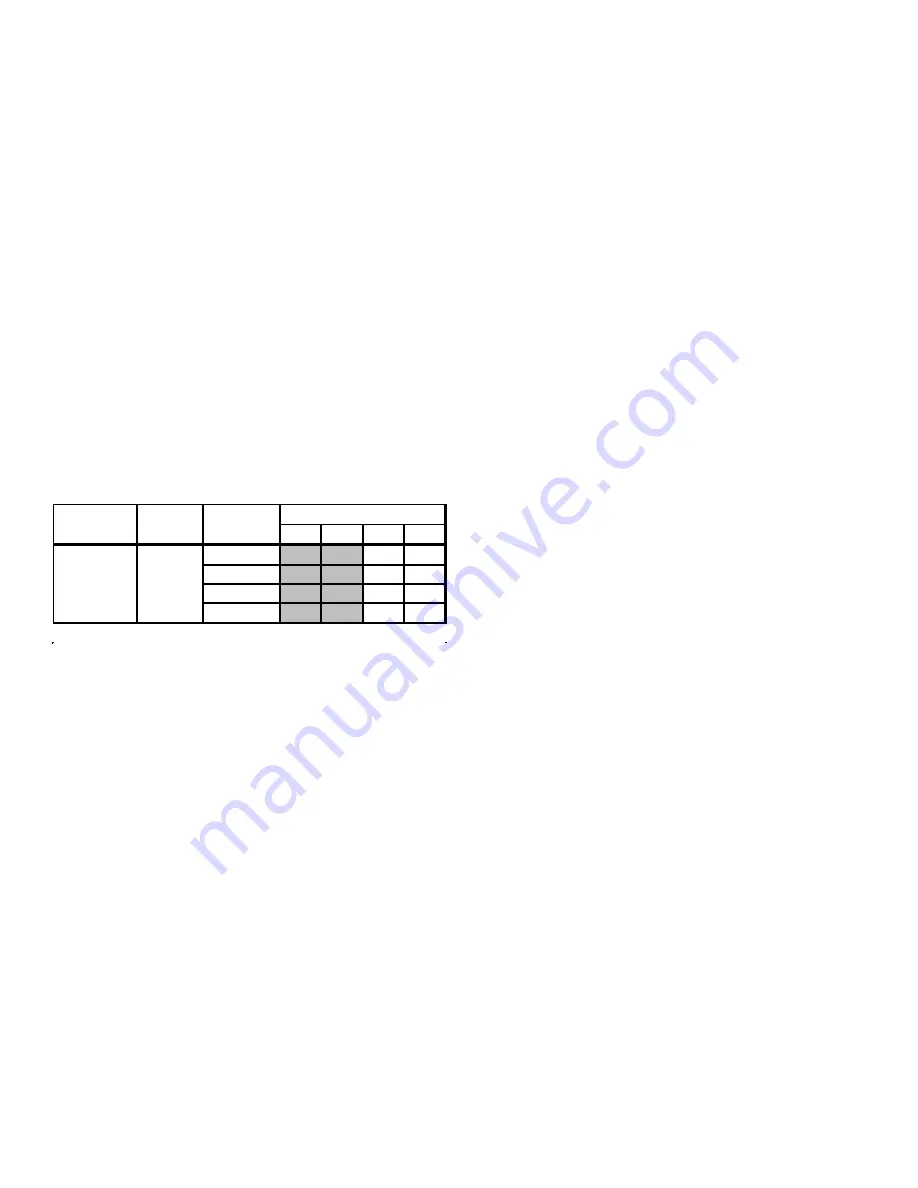

c. Heating speeds are selected DIP switches

S1-4 & S2-1

1. Turn OFF power to the furnace.

2. Select the cooling blower speeds that match the instal

-

lation requirements from the airflow table in this manual

or the Service Manual, If factory cooling speeds do not

match the installation requirements, the dip switch set

-

tings must be changed from factory position

3. Turn ON power to furnace.

4. Verify proper temperature rise in heat mode and CFM in

cooling mode

Blower Heat Off Delay Timings

The integrated control module provides a selectable heat

off delay function. The heat off delay period may be set to

90, 120, 150, 180 seconds using the DIP switches provided

on the control module. The delay is factory shipped at 150

seconds but may be changed to suit the installation require

-

ments and/or homeowner preference. Refer to the following

figures for switch positions and corresponding delay times.

PCBBF139 CONTROL BOARD

1

2

3

4

90

OFF OFF

120

OFF ON

150

ON OFF

180

ON ON

*Factory Setting

S3

PURPOSE

Heating Fan

Off Delay

DIP SWITCH

SWITCH

GROUP FUNCTION

Normal Sequence of Operation

Power Up

•

When power is supplied, the control will energize the

Red LED, microcomputer runs its self-check routine.

• The control will check the status of the gas valve

circuitry.

•

Line polarity is checked.

•

The control then enters standby waiting for a call for

heat or cool.

•

The Furnace status LED will display a slow green

flash signaling standby mode.

Heating Mode

Call for 1st Stage Heat Only:

•

On a call for first stage heat, the thermostat contacts

close signaling the control module.

•

The microcomputer runs its self-check routine.

•

The Amber LED will display a slow flash signaling

normal heat operation.

•

The control module checks the high limit (and/

or auxiliary limit) switch(es) for normally closed

contacts.

• The control checks the low pressure switch for a

shorted condition

•

The gas valve relay status is checked for proper

operation. Once the low pressure switch is detected

open, the inducer blower is energized at high speed

and the humidifier is enabled.

•

The low pressure switch is checked for closure.

•

Once the low pressure switch is closed, the pre-

purge period begins. The inducer will be energized

at high speed for the pre-purge period.

•

Following the completion of pre-purge, the inducer

switches to low speed and the igniter warm up period

begins.

•

After completion of the igniter warm up period:

a. Trial for ignition begins.

b. The first stage of the gas valve is energized.

•

The igniter is de-energized when flame is sensed

or at the conclusion of the ignition activation period

(IAP), whichever comes first.

•

When flame is sensed, the delay to heat on period

begins timing.

•

After the delay to heat on period, the circulator fan

is energized at the low heat speed.

•

The EAC contact is energized with the circulator.

Call for 2nd Stage After First Stage:

•

The inducer motor goes to high speed.

•

The pressure switches are checked for closure.

Closure of the second stage pressure switch will

energize the high fire stage of the gas valve.

•

The high speed circulator output is energized.

NOTE: A call for 2

nd

stage without a call for 1st

stage

will be ignored, and a three amber flash code will be

displayed on the LED. This error code will only be

stored in memory once during a single power cycle.

2nd Stage Satisfied, First Stage Still Calling:

•

When the second stage of the thermostat is satisfied,

the inducer blower is reduced to low speed which

de-energizes the second stage of the gas valve.

•

After the high heat off delay expires, the circulator

is reduced to low heat speed.

•

Note: A call for second stage without a call for first

stage will be ignored.

Cooling Mode

Low stage cooling Mode sequence:

•

On a call for lo cool, the YLO and G thermostat

contacts close signaling the control module.

•

The LED will display a “GREEN”1 flash

•

The compressor and condenser fan are energized.

The compressor is connected to the YLO terminal

of the control module.

•

The circulator fan is energized at lo cool speed after

a cool on delay. The electronic air cleaner will also

be energized.