51

1. Disconnect all power to the furnace. Do not touch the

integrated control module or any wire connected to the

control prior to discharging your body’s electrostatic

charge to ground.

2. Firmly touch a clean, unpainted, metal surface of the

furnace away from the control. Any tools held in a

person’s hand during grounding will be discharged.

3. Service integrated control module or connecting

wiring following the discharge process in step 2. Use

caution not to recharge your body with static electricity;

(i.e., do not move or shuffle your feet, do not touch

ungrounded objects, etc.). If you come in contact with

an ungrounded object, repeat step 2 before touching

control or wires.

4. Discharge your body to ground before removing a new

control from its container. Follow steps 1 through 3 if

installing the control on a furnace. Return any old or

new controls to their containers before touching any

ungrounded object.

Checking Flame Signal

Flame current can be measured in two ways:

1. Putting a D.C. microamp meter in series with the flame

rod

2. Putting a D.C. volt meter across the two solder pads

in the flame current section of the control board.

1 D.C. volt = 1 microamp. See Figure 46.

Flame Current

Solder Pads

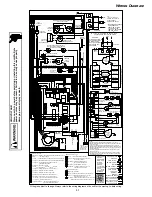

Figure 46

Limit Fault Codes

If the control detects the high limit circuit open, the RED

LED will flash FOUR times and energize the inducer and

indoor blower.

If the limit circuit opens five times within a single call for heat,

the furnace will go into lockout for one hour. The RED LED

will display a FOUR flash code during this time. The control

board can be reset by cycling 115 volt power to the furnace.

If the limit circuit opens and does not close within five minutes,

the control assumes the blower has failed the RED LED will

flash ELEVEN times.

If the limit circuit opens and does not close within fifteen

minutes, the control assumes the manual rollout or fuse

has opened and the RED LED will flash FIVE times. The

control will enter a one hour lockout and the inducer will run

continuously.

In an open limit condition the red LED will flash as described

above but the error code will not be stored in memory until

the limit resets or until 15 minutes has elapsed. So if the limit

resets in less than 5 minutes a four flash code will be stored.

If the limit resets in more than 5 but less than 15 minutes, an

eleven flash code will be stored. If the limit is still open after

15 minutes, a five flash code will be stored.

Diagnostic Chart

Refer to the

Troubleshooting Chart

in the back of this manual

for assistance in determining the source of unit operational

problems.

External Lockout

-

A control lockout resulting from an external fault

sensed by the control, such as an unsuccessful

recycle or retry period, or a limit trip. Once in

External Lockout, the control will shut down for a

period of one hour before attempting another trial

for ignition.

Internal Lockout

-

A failure internal to the control board.

Fault Recall

Retrieving Fault Codes

To retrieve fault codes, push and release the “LAST ERROR”

button for more than 1/ 5 second and less than 5 seconds (the

LED will indicate this period by solid GREEN for 1/5 second

to 5 seconds). The LED will flash up to five stored fault codes,

beginning with the most recent. If there are no fault codes

in memory, the LED will flash two green flashes. The control

will flash the most recent error first and the oldest error last.

If multiple faults exist there will be 2 seconds between codes.

Solid LED error codes will not be displayed.