4. Insert one end of the Anode Support into the anode button,

then the other as shown in Fig. 3-5.

5.

6.

Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

DISASSEMBLY INSTRUCTIONS

CRT

Support

Fig. 3-5

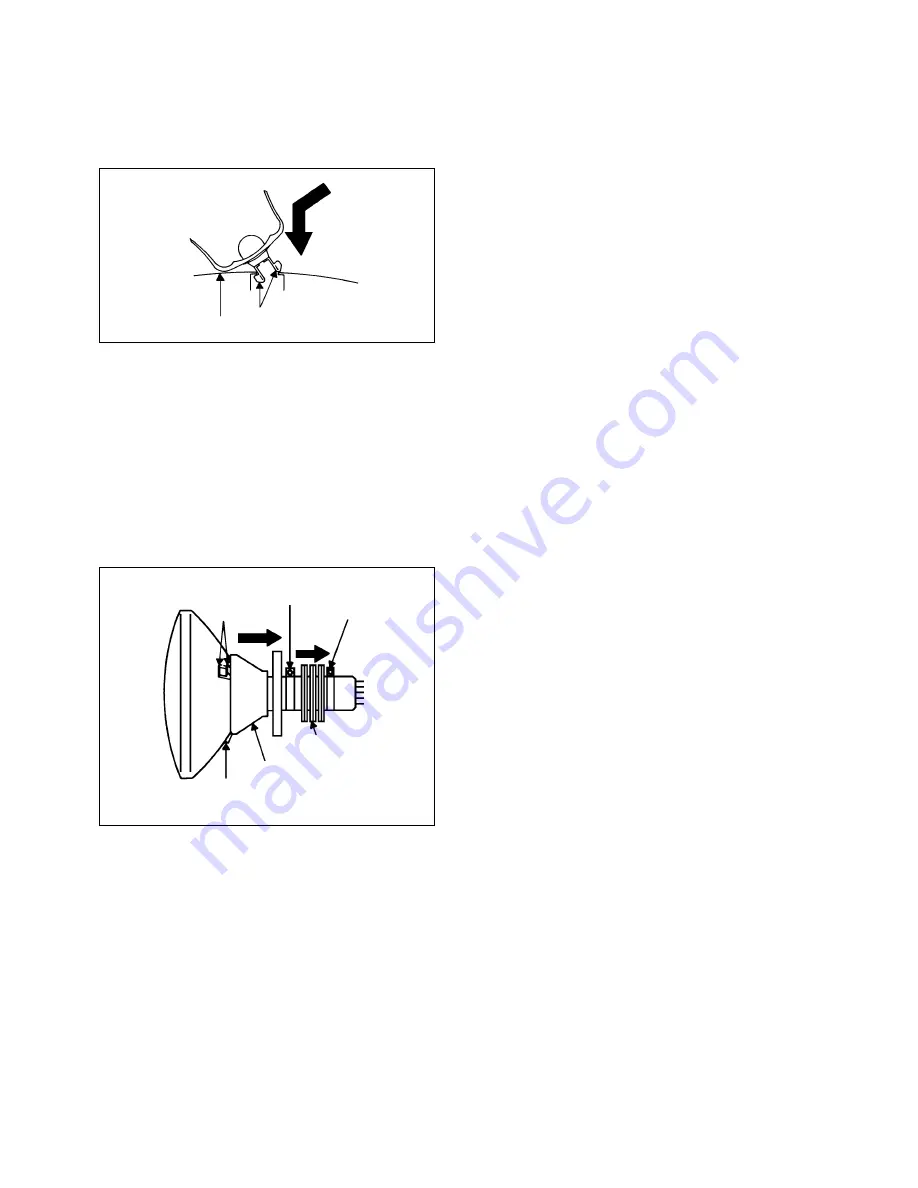

4. REMOVAL OF DEFLECTION YOKE

(Refer to Fig. 4-1)

1.

2.

3.

4.

5.

Loosen the screw

1

.

Remove the Convergence • Purity Magnet in the

direction of arrow (A).

Loosen the screw

2

.

Remove the 3 Wedges.

Remove the Deflection Yoke in the direction of arrow

(B).

Wedge

Wedge

Deflection Yoke

Convergence •

Purity Magnet

2

1

(A)

(B)

Fig. 4-1

INSTALLATION

Install new Deflection Yoke in reverse steps of REMOVAL.

NOTE

After adjusting the purity and the convergence, fix the

screw

2

and lock the wedges.

B3-2