STEP 2 - PRE-ASSEMBLY

2.1

Read entire installation manual

before

beginning installation of the G-Force® BX ILD.

2.2

Tools and materials typically needed to install/assemble a G-Force® BX ILD are as follows:

•

Hand tools

•

Plastic cable tie straps

•

Ladders/man lifts

2.3

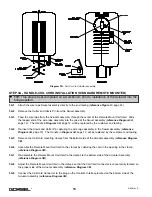

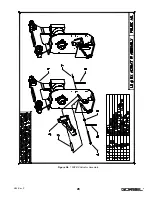

Prior to installing the G-Force® BX ILD, it is a good idea to familiarize yourself with the main components.

-

Reference the following layout drawings:

•

Figure I1

, page 65 - 150# BX Standard Inline Component Layout

•

Figure I2

, page 66 - 300/380# BX Standard Inline Component Layout

•

Figure I3

, page 67 - Standard Remote Mount Component Layout

•

Figure I4

, page 68 - Float Mode Remote Mount Component Layout

STEP 3 - HANDLE-COIL CORD INSTALLATION (STANDARD INLINE)

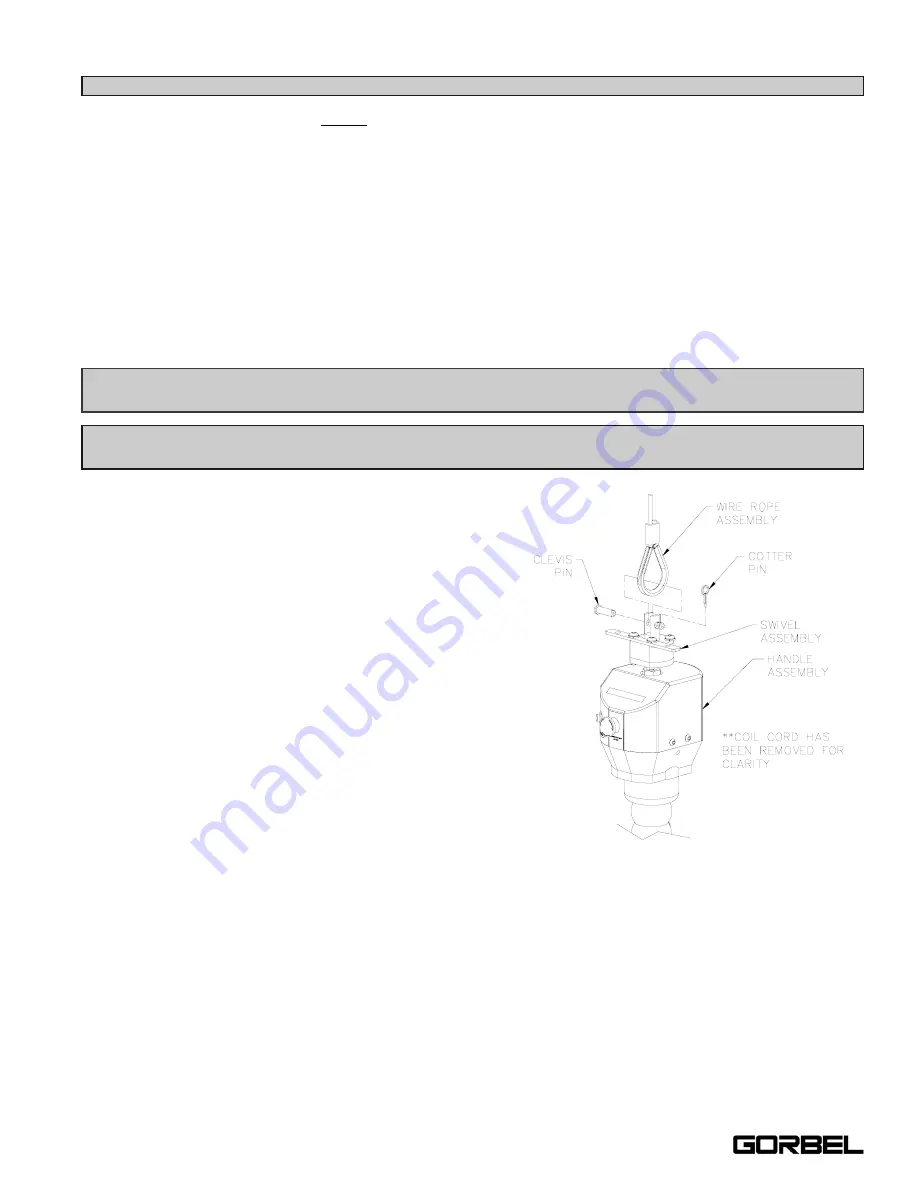

3.1

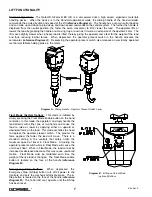

Remove the Cotter and Clevis Pin from the Handle swivel

assembly.

3.2

Feed the wire rope from the Actuator assembly through

the center of the Coil Cord. Slide the looped end of the

wire rope assembly into the yoke of the Handle swivel

assembly (

reference Diagram 3A

).

3.3

Re-insert the Clevis and Cotter Pin capturing the wire

rope assembly in the Handle swivel assembly (

reference

Diagram 3A

).

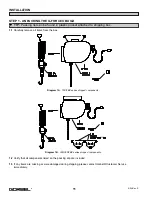

3.4

Remove the Coil Cord mounting clamps from the bottom

side of the Actuator assembly (

reference Diagram 3B

,

page 13).

3.5

Assemble the Coil Cord to the clamps by capturing the

cord in the opening in the clamp (

reference Diagram 3B

,

page 13).

3.6

Re-assemble the Coil Cord mounting clamps to the

bottom side of the Actuator assembly (

reference

Diagram 3B

, page 13).

3.7

Adjust the Coil Cord in the clamps so that the Coil Cord

Connector is conveniently located on the proper side of

the Actuator assembly (

reference Diagram 3B

, page 13).

3.8

Connect the Coil Cord Connector to the plug on the Control’s Interface located on the bottom side of the

Actuator assembly (

reference Diagram 3B

, page 13).

3.9

Assure that the coils of the Coil Cord are centered around the wire rope when properly installed. When the

proper alignment of the Coil Cord has been achieved, finish clamping the hardware to fix the Coil Cord in place

(

reference Diagram 3B

, page 13).

Continue to Step 4 on Page 15.

TIP:

This step is best completed on a workbench, prior to installation of the Actuator into the

bridge system.

Diagram 3A.

Handle to Wire Rope assembly.

12

Note:

For Standard Remote Mounted Handle-Coil Cord Installation, go to Step 3A, page 13.

For Float Mode Remote Mounted Handle-Coil Cord Installation, go to Step 3B, page 14.

4/04-Rev. S

®

Summary of Contents for 150 BX G-Force

Page 26: ...Figure A3 bottom Figure A4 top 150 BX Actuator Assembly 25 4 04 Rev S ...

Page 27: ...Figure A5 150 BX Actuator Assembly 26 4 04 Rev S ...

Page 28: ...Figure A6 150 BX Actuator Assembly 27 4 04 Rev S ...

Page 29: ...Figure A7 bottom Figure A8 top 150 BX Actuator Assembly 28 4 04 Rev S ...

Page 30: ...Figure A9 bottom Figure A10 top 150 BX Actuator Assembly 29 4 04 Rev S ...

Page 31: ...Figure A11 bottom Figure A12 top 150 BX Actuator Assembly 30 4 04 Rev S ...

Page 32: ...Figure A13 150 BX Actuator Assembly 31 4 04 Rev S ...

Page 33: ...Figure A14 150 BX Actuator Assembly 32 4 04 Rev S ...

Page 35: ...Figure B3 bottom Figure B4 top 300 380 BX Actuator Assembly 34 4 04 Rev S ...

Page 36: ...Figure B5 300 380 BX Actuator Assembly 35 4 04 Rev S ...

Page 37: ...Figure B6 300 380 BX Actuator Assembly 36 4 04 Rev S ...

Page 38: ...Figure B7 bottom Figure B8 top 300 380 BX Actuator Assembly 37 4 04 Rev S ...

Page 39: ...Figure B9 bottom Figure B10 top 300 380 BX Actuator Assembly 38 4 04 Rev S ...

Page 40: ...Figure B11 bottom Figure B12 top 300 380 BX Actuator Assembly 39 4 04 Rev S ...

Page 41: ...40 Figure B13 300 380 BX Actuator Assembly 4 04 Rev S ...

Page 42: ...Figure B14 300 380 BX Actuator Assembly 41 4 04 Rev S ...

Page 44: ...Figure C3 Standard Handle Assembly 43 4 04 Rev S ...

Page 45: ...Figure C4 Standard Handle Assembly 44 4 04 Rev S ...

Page 46: ...Figure C5 bottom Figure C6 top Standard Handle Assembly 45 4 04 Rev S ...

Page 47: ...Figure C7 bottom Figure C8 top Standard Handle Assembly 46 4 04 Rev S ...

Page 48: ...Figure C9 bottom Figure C10 top Standard Handle Assembly 47 4 04 Rev S ...

Page 49: ...Figure C11 bottom Figure C12 top Standard Handle Assembly 48 4 04 Rev S ...

Page 50: ...Figure C13 Standard Handle Assembly 49 4 04 Rev S ...

Page 52: ...Figure D3 bottom Figure D4 top Float Mode Handle Assembly 51 4 04 Rev S ...

Page 53: ...Figure D5 bottom Figure D6 top Float Mode Handle Assembly 52 4 04 Rev S ...

Page 54: ...Figure D7 bottom Figure D8 top Float Mode Handle Assembly 53 4 04 Rev S ...

Page 55: ...Figure D9 bottom Figure D10 top Float Mode Handle Assembly 54 4 04 Rev S ...

Page 56: ...Figure D11 Float Mode Handle Assembly 55 4 04 Rev S ...

Page 58: ...Figure E2 Air Coil Cord Assembly Standard Float Mode 57 4 04 Rev S ...

Page 59: ...Figure E3 Remote Mount Coil Cord Standard Float Mode 58 4 04 Rev S ...

Page 60: ...Figure E4 Air Remote Mount Coil Cord Standard Float Mode 59 4 04 Rev S ...

Page 61: ...APPENDIX F CONTROLS SCHEMATIC DRAWINGS Figure F1 Remote Load Cell Assembly 60 4 04 Rev S ...

Page 62: ...Figure F2 BX Controls Schematic 61 4 04 Rev S ...

Page 64: ...Figure G2 BX G Force 300 380 Overall Dimensions 63 4 04 Rev S ...

Page 67: ...Figure I2 300 380 Standard Inline Component Layout 66 4 04 Rev S ...

Page 68: ...Figure I3 Standard Remote Mount Component Layout 67 4 04 Rev S ...