4

G-Force® Operational Guidelines

All operators should read the G-Force® Instruction, Installation and Maintenance Manuals before

operating the unit. Please follow the instructions contained in these manuals for your safety and

for optimum trouble-free operation of your G-Force®. When repairing or maintaining a

G-Force®, use only Gorbel® recommended parts and materials.

Read & follow all instruction

& warning information on or

attached to the G-Force

®

.

Check Wire Rope for

improper seating, twisting,

kinking, wear or defects

before operating.

Center G-Force

®

over the

load before lifting a load.

Do not end or side load.

Avoid swinging of load or

load hook when traveling

with the G-Force

®

.

Check the coil cord for

improper seating, twisting,

kinking, wear or defects

before operating.

Do not over-twist coil cable

assembly (>360°).

Damage and/or failure

could occur.

The Operator Present

switch should be depressed

the entire time the

G-Force

®

is in use.

Press Float Mode Button with

only the load weight hanging

from unit. Applying other

force will cause unit to drift.

The wire rope should never

be more than 20° out of

vertical while the

G-Force

®

is in use.

Do not bang the G-Force

®

into end stops repeatedly

or at a speed faster than a

normal walking pace.

G-Force®

Installation

&

Maintenance

Manual

1

10

9

8

7

6

5

2

Questions about G-Force

®

?

Call Gorbel

®

Customer

Service at (800) 821-0086 or

your local Gorbel

®

distributor.

?

12

Maximum Trolley Saddle for

the G-Force

®

is 12'.

See drawing for Trolley

Saddle definitions by unit size.

Maximum

Trolley

Saddle is

12'.

What is Trolley

Saddle?

150# unit:

The distance

from bottom of

wheels to floor.

300/380# unit:

The distance

from hoist trolley

clevis pin to the

floor.

11

4

3

4/04-Rev. S

®

Summary of Contents for 150 BX G-Force

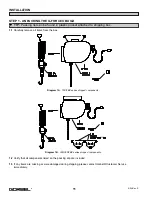

Page 26: ...Figure A3 bottom Figure A4 top 150 BX Actuator Assembly 25 4 04 Rev S ...

Page 27: ...Figure A5 150 BX Actuator Assembly 26 4 04 Rev S ...

Page 28: ...Figure A6 150 BX Actuator Assembly 27 4 04 Rev S ...

Page 29: ...Figure A7 bottom Figure A8 top 150 BX Actuator Assembly 28 4 04 Rev S ...

Page 30: ...Figure A9 bottom Figure A10 top 150 BX Actuator Assembly 29 4 04 Rev S ...

Page 31: ...Figure A11 bottom Figure A12 top 150 BX Actuator Assembly 30 4 04 Rev S ...

Page 32: ...Figure A13 150 BX Actuator Assembly 31 4 04 Rev S ...

Page 33: ...Figure A14 150 BX Actuator Assembly 32 4 04 Rev S ...

Page 35: ...Figure B3 bottom Figure B4 top 300 380 BX Actuator Assembly 34 4 04 Rev S ...

Page 36: ...Figure B5 300 380 BX Actuator Assembly 35 4 04 Rev S ...

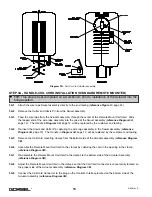

Page 37: ...Figure B6 300 380 BX Actuator Assembly 36 4 04 Rev S ...

Page 38: ...Figure B7 bottom Figure B8 top 300 380 BX Actuator Assembly 37 4 04 Rev S ...

Page 39: ...Figure B9 bottom Figure B10 top 300 380 BX Actuator Assembly 38 4 04 Rev S ...

Page 40: ...Figure B11 bottom Figure B12 top 300 380 BX Actuator Assembly 39 4 04 Rev S ...

Page 41: ...40 Figure B13 300 380 BX Actuator Assembly 4 04 Rev S ...

Page 42: ...Figure B14 300 380 BX Actuator Assembly 41 4 04 Rev S ...

Page 44: ...Figure C3 Standard Handle Assembly 43 4 04 Rev S ...

Page 45: ...Figure C4 Standard Handle Assembly 44 4 04 Rev S ...

Page 46: ...Figure C5 bottom Figure C6 top Standard Handle Assembly 45 4 04 Rev S ...

Page 47: ...Figure C7 bottom Figure C8 top Standard Handle Assembly 46 4 04 Rev S ...

Page 48: ...Figure C9 bottom Figure C10 top Standard Handle Assembly 47 4 04 Rev S ...

Page 49: ...Figure C11 bottom Figure C12 top Standard Handle Assembly 48 4 04 Rev S ...

Page 50: ...Figure C13 Standard Handle Assembly 49 4 04 Rev S ...

Page 52: ...Figure D3 bottom Figure D4 top Float Mode Handle Assembly 51 4 04 Rev S ...

Page 53: ...Figure D5 bottom Figure D6 top Float Mode Handle Assembly 52 4 04 Rev S ...

Page 54: ...Figure D7 bottom Figure D8 top Float Mode Handle Assembly 53 4 04 Rev S ...

Page 55: ...Figure D9 bottom Figure D10 top Float Mode Handle Assembly 54 4 04 Rev S ...

Page 56: ...Figure D11 Float Mode Handle Assembly 55 4 04 Rev S ...

Page 58: ...Figure E2 Air Coil Cord Assembly Standard Float Mode 57 4 04 Rev S ...

Page 59: ...Figure E3 Remote Mount Coil Cord Standard Float Mode 58 4 04 Rev S ...

Page 60: ...Figure E4 Air Remote Mount Coil Cord Standard Float Mode 59 4 04 Rev S ...

Page 61: ...APPENDIX F CONTROLS SCHEMATIC DRAWINGS Figure F1 Remote Load Cell Assembly 60 4 04 Rev S ...

Page 62: ...Figure F2 BX Controls Schematic 61 4 04 Rev S ...

Page 64: ...Figure G2 BX G Force 300 380 Overall Dimensions 63 4 04 Rev S ...

Page 67: ...Figure I2 300 380 Standard Inline Component Layout 66 4 04 Rev S ...

Page 68: ...Figure I3 Standard Remote Mount Component Layout 67 4 04 Rev S ...