Overload:

The servo controller will prevent the lift from moving upward if loaded beyond the maximum capacity of the

G-Force® BX ILD. When an overload condition is sensed, the Overload indicator is illuminated and the lift is

prevented from moving upward. The lift may be moved down to allow for the safe removal of the load. Releasing and

reactivating the operator present switch resets the overload condition.

Limit Switches:

The G-Force® is equipped with both mechanical Upper and Lower Limit switches, located in the

Actuator assembly. When the Upper Limit switch is triggered, the upward motion of the lift stops quickly at a controlled

deceleration rate. The controlled deceleration rate guarantees the load cannot come off the hook. When the Upper

Limit is triggered, the lift will move down but not up. The lower limit is set so that a minimum of two (2) full wraps of

wire rope remain on the drum pulley at all times. When the Lower Limit switch is triggered, the downward motion of

the lift stops quickly at a controlled deceleration rate. When the Lower Limit is triggered, the lift will only move up and

not down.

Slack Switch:

The G-Force® is equipped with a pair of Slack Switches that sense tension in the wire rope and trips

when the wire rope develops slack. The switches are located inside the Actuator assembly. When the Slack Switches

sense slack in the wire rope, downward movement of the lift is stopped to minimize the amount of wire rope unwound

from the drum pulley. When slack in the wire rope is sensed, the lift will only move up but not down.

Remote Mount Handle (System Option):

The lifting device is capable of operating with the handle displaced from

the wire rope (not in-line with the wire rope). For example, if an end user has tooling that is too large for the operator

to safely reach and operate the handle in the standard position, remote mounting the handle is recommended. The

tooling must be mounted (and balanced) on the end of the wire rope, while the handle can be remote mounted. The

tooling

must

be attached to the end of the wire rope with a swivel assembly (supplied by Gorbel, Inc.). Failure to mount

the tooling with a swivel assembly can result in premature failure of both the wire rope and the coil cord. The remote

mounted handle is linked to the coil cord via extension cables and connectors. The handle operates exactly the same

as if it were mounted in-line. If the device is equipped for Float Mode, a load cell assembly is provided that must also

be mounted between the tooling and the end of the wire rope. The handle is linked to the load cell via an extension

cable and connectors. **The end user must supply Gorbel, Inc., with the required length of the extension cables such

that they can be safely routed and clamped to the tooling. Always include the distance for bends and turns when

providing the extension length.

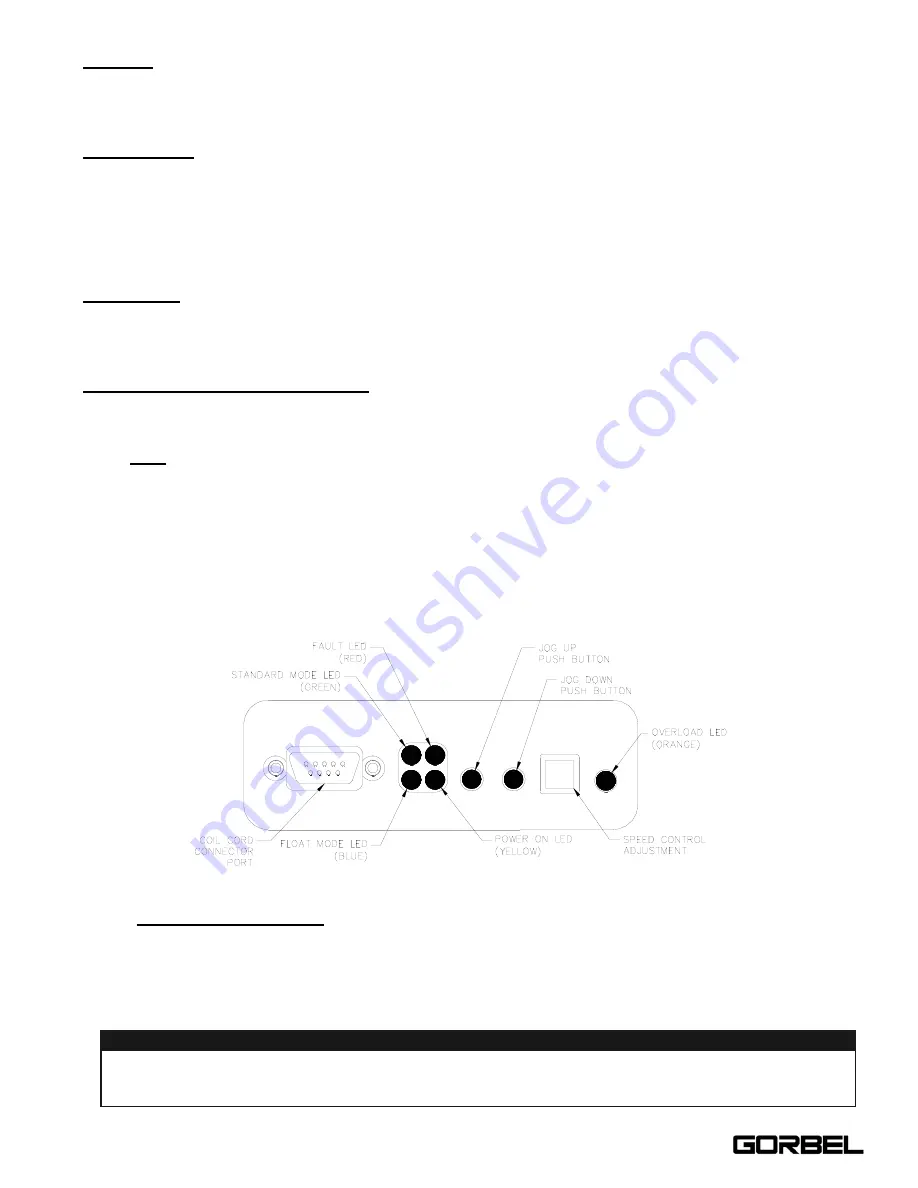

CONTROLS INTERFACE FEATURES

1.

Jog Switch Push Buttons:

The Jog Switch Buttons allow qualified personnel to replace the wire rope (load

cable) on the system. To effectively operate the Jog Switch Buttons, all electrical cables must be connected and

power on. Depressing the “Up” jog switch button will enable the motor and cause the system to reel the wire

rope into the actuator and onto the main pulley. Depressing the “Down” jog switch button will enable the motor

and cause the system to pay out the wire rope from the actuator and off of the main pulley. The handle and

operator present switch are not to be operated during use of the Jog Switch Buttons.

Diagram C.

Controls Interface Display.

WARNING

The Jog Switch buttons are for system maintenance and load testing use only, and should not be

manipulated during normal operation of the G-Force® BX ILD. Operation of the Jog Switch buttons dur-

ing normal operation increases the risk of personal injury to the operator.

8

4/04-Rev. S

®

Summary of Contents for 150 BX G-Force

Page 26: ...Figure A3 bottom Figure A4 top 150 BX Actuator Assembly 25 4 04 Rev S ...

Page 27: ...Figure A5 150 BX Actuator Assembly 26 4 04 Rev S ...

Page 28: ...Figure A6 150 BX Actuator Assembly 27 4 04 Rev S ...

Page 29: ...Figure A7 bottom Figure A8 top 150 BX Actuator Assembly 28 4 04 Rev S ...

Page 30: ...Figure A9 bottom Figure A10 top 150 BX Actuator Assembly 29 4 04 Rev S ...

Page 31: ...Figure A11 bottom Figure A12 top 150 BX Actuator Assembly 30 4 04 Rev S ...

Page 32: ...Figure A13 150 BX Actuator Assembly 31 4 04 Rev S ...

Page 33: ...Figure A14 150 BX Actuator Assembly 32 4 04 Rev S ...

Page 35: ...Figure B3 bottom Figure B4 top 300 380 BX Actuator Assembly 34 4 04 Rev S ...

Page 36: ...Figure B5 300 380 BX Actuator Assembly 35 4 04 Rev S ...

Page 37: ...Figure B6 300 380 BX Actuator Assembly 36 4 04 Rev S ...

Page 38: ...Figure B7 bottom Figure B8 top 300 380 BX Actuator Assembly 37 4 04 Rev S ...

Page 39: ...Figure B9 bottom Figure B10 top 300 380 BX Actuator Assembly 38 4 04 Rev S ...

Page 40: ...Figure B11 bottom Figure B12 top 300 380 BX Actuator Assembly 39 4 04 Rev S ...

Page 41: ...40 Figure B13 300 380 BX Actuator Assembly 4 04 Rev S ...

Page 42: ...Figure B14 300 380 BX Actuator Assembly 41 4 04 Rev S ...

Page 44: ...Figure C3 Standard Handle Assembly 43 4 04 Rev S ...

Page 45: ...Figure C4 Standard Handle Assembly 44 4 04 Rev S ...

Page 46: ...Figure C5 bottom Figure C6 top Standard Handle Assembly 45 4 04 Rev S ...

Page 47: ...Figure C7 bottom Figure C8 top Standard Handle Assembly 46 4 04 Rev S ...

Page 48: ...Figure C9 bottom Figure C10 top Standard Handle Assembly 47 4 04 Rev S ...

Page 49: ...Figure C11 bottom Figure C12 top Standard Handle Assembly 48 4 04 Rev S ...

Page 50: ...Figure C13 Standard Handle Assembly 49 4 04 Rev S ...

Page 52: ...Figure D3 bottom Figure D4 top Float Mode Handle Assembly 51 4 04 Rev S ...

Page 53: ...Figure D5 bottom Figure D6 top Float Mode Handle Assembly 52 4 04 Rev S ...

Page 54: ...Figure D7 bottom Figure D8 top Float Mode Handle Assembly 53 4 04 Rev S ...

Page 55: ...Figure D9 bottom Figure D10 top Float Mode Handle Assembly 54 4 04 Rev S ...

Page 56: ...Figure D11 Float Mode Handle Assembly 55 4 04 Rev S ...

Page 58: ...Figure E2 Air Coil Cord Assembly Standard Float Mode 57 4 04 Rev S ...

Page 59: ...Figure E3 Remote Mount Coil Cord Standard Float Mode 58 4 04 Rev S ...

Page 60: ...Figure E4 Air Remote Mount Coil Cord Standard Float Mode 59 4 04 Rev S ...

Page 61: ...APPENDIX F CONTROLS SCHEMATIC DRAWINGS Figure F1 Remote Load Cell Assembly 60 4 04 Rev S ...

Page 62: ...Figure F2 BX Controls Schematic 61 4 04 Rev S ...

Page 64: ...Figure G2 BX G Force 300 380 Overall Dimensions 63 4 04 Rev S ...

Page 67: ...Figure I2 300 380 Standard Inline Component Layout 66 4 04 Rev S ...

Page 68: ...Figure I3 Standard Remote Mount Component Layout 67 4 04 Rev S ...