INSTALLATION

STEP 1 - PRE-ASSEMBLY

1.1

Check packing list to make sure correct quantity of parts is included.

1.2

Tools and materials (by others) typically needed to assemble crane are as follows:

• Ladders/man lifts

• Tape measure, combination wrenches, socket sets

• Large square

• Lifting sling (rated for 4000 lbs. capacity minimum)

• Mallet

• Leveling tools (transit, laser level, water level, etc.)

• Shop brush

• Lifting device to lift heavy Gantry Crane components

• Torque wrench (200 ft.-lbs.

• Safety equipment (hard hats, barricades, etc.)

capable)

WARNING

Equipment described herein is not designed for, and should not be used for, lifting, supporting or

transporting humans. Failure to comply with any one of the limitations noted herein can result in

serious bodily injury and/or property damage. Check State and Local regulations for any

additional requirements.

WARNING

Crane cannot be utilized as a ground: A separate ground wire is required. For example,

systems with 3-phase power require three conductors plus one ground wire.

WARNING

Reference the American Institute of Steel Construction (AISC) Manual of Steel Construction

(9th edition), Part 5, Specification for Structural Joints using ASTM A325 or A490 Bolts (section

8.d.2) for the proper procedures to follow when using any torque tightening method.

TIP:

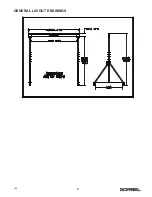

Packing list can be found in plastic pocket inside hardware box: General

Arrangement Drawing can be found inserted in this installation manual.

2

9/19

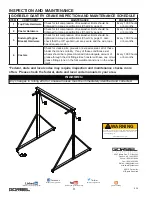

WARNING

Gantry Crane should not be moved when loaded.

WARNING

Gantry Crane should not be moved by pushing or pulling on load.

WARNING

Gantry Crane should be used on a level, flat, smooth surface which is free of defects and

obstructions.