STEP 3 - CASTER TO BASE CHANNEL CONNECTIONS

3.1

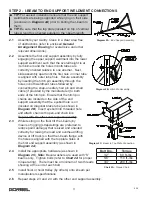

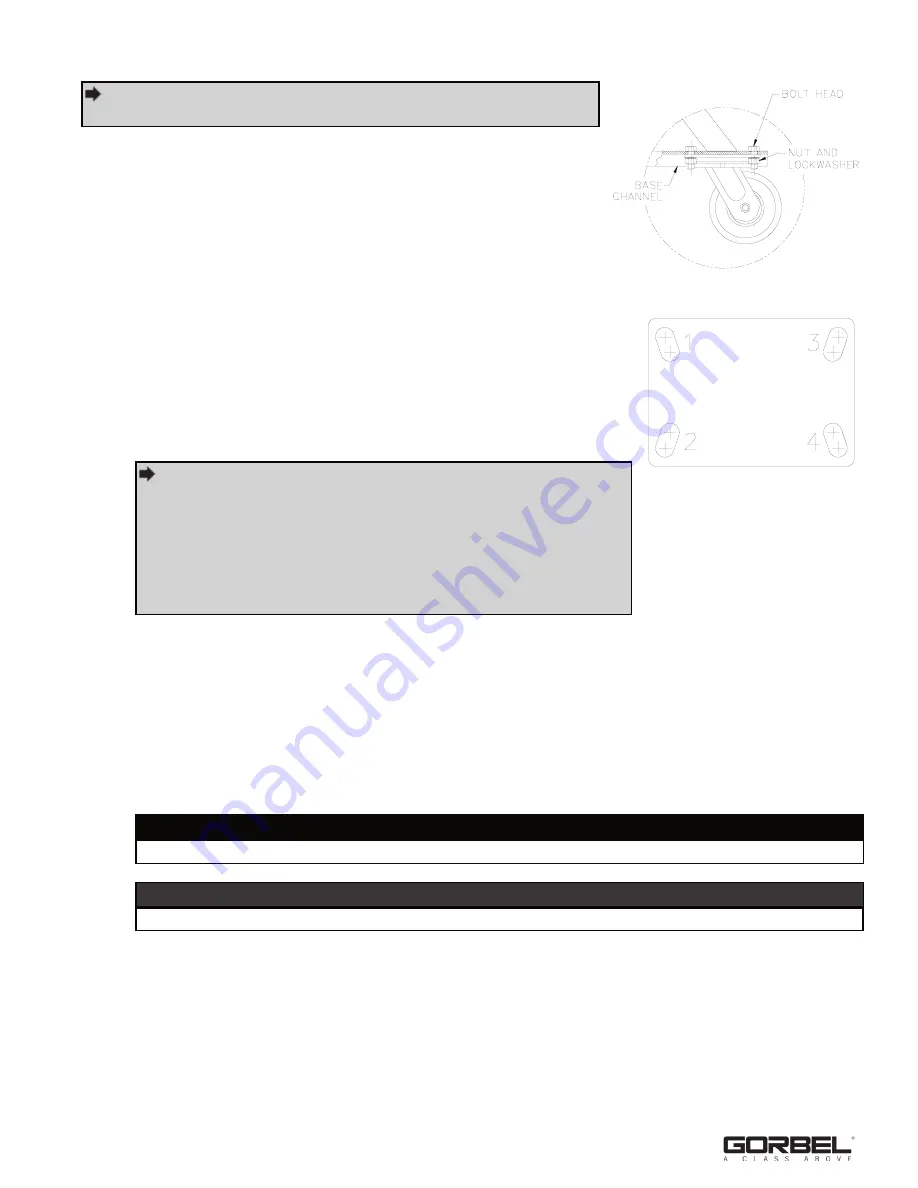

Assemble the appropriate hardware so that the heads of

the sixteen 1-1/2” long hex head bolts are located on the

top surface of the base channel (as shown in

Diagram 3A

).

3.2 For 1, 2 and 5 Ton Gantry Cranes utilizing optional

4-Position Swivel Locks only:

The optional 4-Position

Swivel Locks (4PSL) are installed via a bolted connection

(unlike the 3 Ton Gantry Cranes which accept a 4PSL

that is pre-welded to the caster). Ensure that the 4PSL’s

are installed on the under-side of the caster base plate.

To install the 4PSL’s align the two slotted holes in the swivel

lock with two slotted holes (either holes 1 & 2 only or holes

3 & 4 only) on the short side of the caster base plate (as

shown in

Diagram 3B

).

3.3

Tighten caster hardware (refer to

Chart 2A

, on page 3, for proper torque rating).

3.4

You are now ready to erect the assembled Gantry Crane into the upright position. Ensure

that the hitch pin assemblies are still properly engaged in upper and lower vertical tube

holes and that the safety hair pins are intact.

Carefully and safely

(by means of rigging

(straps/slings are preferred to reduce paint damage) that is sized and oriented correctly for

raising the load) lift and rotate the Gantry Crane onto its casters by means of an overhead

lifting device or lift truck. Use Gorbel® Blue touch-up paint (provided) to cover any

scratches and abrasions as needed.

3.5

If your Gantry Crane is equipped with the optional cam brakes (pre-installed prior to

receiving them) you may use your hand or foot to engage the brake for each caster by

pressing down on one of the cam brake foot pedals located on the sides of the casters.

Try moving the Gantry Crane after engaging the cam brakes to ensure that they are

properly engaged.

3.6 For Gantry Cranes utilizing optional Steel V-Groove Casters only:

Install the

assembled Gantry Crane onto the V-Track per the manufacturer’s instructions.

TIP:

To install casters, assemble while the Gantry Crane is

still lying on its side (as shown in

Diagram 2A

on pg. 3).

TIP:

Choose the 2 outer-most slotted holes when

mounting the 4PSL. This will ensure that the 4PSL pull

ring will be accessible from the outside of the formed

base channel allowing you to engage or disengage the

spring loaded pin from the locking caster slots. If the

4PSL is pre-welded to the caster simply rotate the caster

assembly so that the 4PSL faces outward.

Diagram 3A.

Caster Assembly.

Diagram 3B.

Caster Base Plate.

WARNING

Ensure that NO ONE is standing near or in the vicinity of the crane while it is being erected.

WARNING

Ensure there are no other obstructions that might hinder the crane from being erected.

4

9/19