STEP 6 - HOIST TROLLEY INSTALLATION

6.1

If your hoist trolley looks like:

150#, 250#, 500#, 1000# and 2000# Hoist Trolley

6.2

Clean inside flanges of track with a clean, dry cloth (

do not use any kind of cleaning

solution

) to remove grit or debris that may have collected during shipping, storage, or

installation.

6.3

Be sure end stop is installed opposite the festooning end of bridge/monorail.

6.4

Attach hoist to hoist trolley by snapping hoist suspension hook over the trolley saddle

clevis pin of hoist trolley.

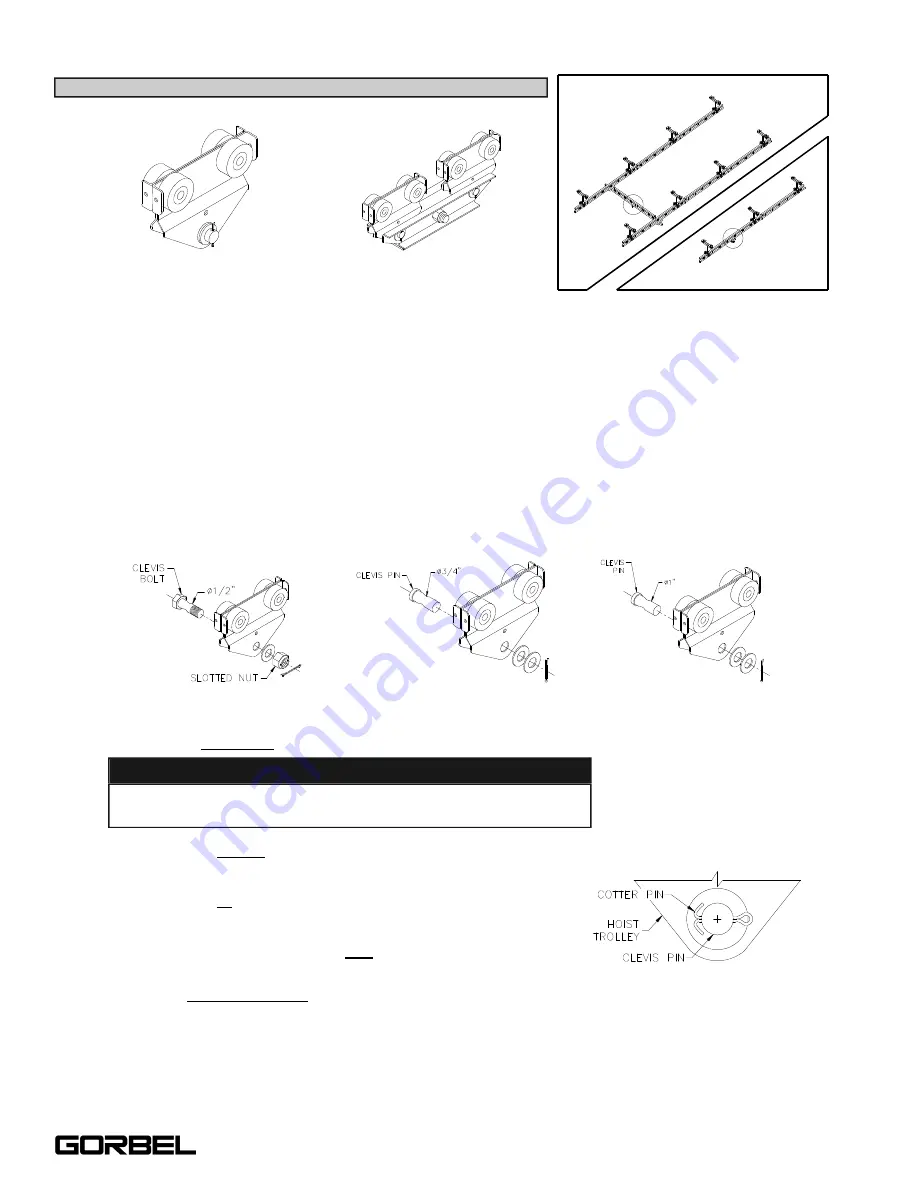

6.5

If hoist suspension is too large or hoist has a suspension device other than a hook,

remove trolley saddle clevis pin and install suspension device (by others). Insert clevis

pin back into place. Slide washers on clevis pin and insert cotter pin through trolley

saddle clevis pin (

diagrams 6A, 6B,

and

6C

).

6.6

Bend back both legs of cotter pin (

diagram 6D

).

6.7

If a tow arm is not

being utilized on the trolley, go to

Step 6.12, on page 15.

If a tow arm is

being utilized on the trolley, go to Step

6.8, on page 15.

Note:

Festoon tow arms are

not

recommended for use

on 4000# systems or systems with extended end trucks.

They are

not necessary

for systems with festoon trolleys.

(shipped assembled)

go to Step 6.2

(shipped assembled)

go to Step 6.15

Diagram 6A.

Installing hoist on

150-250# hoist trolley.

Diagram 6B.

Installing hoist on

500# hoist trolley.

Diagram 6C.

Installing hoist on

1000-2000# hoist trolley.

WARNING

Fully bend both legs of cotter pin (

diagram 6D

).

If cotter

pin is cracked or fatigued it must be replaced.

Diagram 6D.

Installing cotter pin

through trolley saddle clevis pin.

14

9/05

Bridge Crane

Monorail

Summary of Contents for AL 1000

Page 1: ......