STEP 7 - FESTOON STACK SECTION INSTALLATION

7.1

Remove end stop on festooning end of runway/monorail.

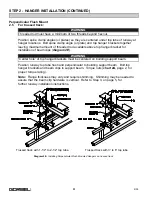

For All Systems With Festoon Gliders, or Systems

With Festoon Trolleys and 1000, 2000, or 4000 Series

Track (

diagram 7A

)

7.2

Slide festoon stack section over open

runway/monorail end.

7.3

Re-install end stop (

diagram 7A

).

7.4

Use leveling screws located at top of

festoon stack section to align it with the

runway/monorail.

For Systems With Festoon Trolleys

and 250 or 500 Series Track (

diagram 7B

)

Note

:

Welding is required to attach festoon stack section to runway/monorail when using

festoon trolleys with 250 or 500 series track.

7.5

Slide festoon stack section over open runway/monorail end.

7.6

Use leveling screws located at top of festoon stack section to align it with runway/monorail.

7.7

Weld festoon stack section to runway/monorail at locations (

diagram 7B

).

Note:

Because trolleys are too large to roll under the end stop on the 250 and 500 series

track, the end stop and accompanying hardware (which held the festoon stack section to

the runway/monorail) is positioned

at the end of the festoon stack

section. To prevent festoon stack

section from sliding off the

runway/monorail, the festoon

stack section is welded.

7.8

Install end stop (removed in step

7.1) in end of festoon stack

section (

diagram 7B

).

TIP:

Festoon stack section allows festooning to stack up at

the end of the system, permitting full use of

runway/monorail.

Æ

Æ

Æ

Festoon Glider

Festoon Trolley

Diagram 7A.

Installing festoon stack section.

WARNING

Do not “over tighten”

leveling screws: this will cause permanent damage to the track.

WARNING

All welds must meet American Welding Society (AWS) specification D1.1 using E70xx

electrodes.

Diagram 7B.

Welding festoon stack section on 250-500# series track.

17

9/05

Bridge Crane

Monorail

Summary of Contents for AL 1000

Page 1: ......