STEP 3 - PIVOT PRO® (FREE STANDING) MAST INSTALLATION

3.1 INSTALLING ANCHOR BOLTS

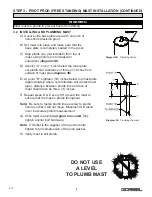

3.1.1 Square Base Plates

(4-bolt

pattern):

A) Anchor bolts (by others) for

base plates must:

• be 3/4” in diameter.

• be embedded at least 4” into

floor, not to exceed 3/4 of floor

depth

(see

diagram 3A

).

Note:

A minimum 6” thick

reinforced concrete floor is

required

(

see

diagram 3B

).

• have

minimum

of two threads above nut after

installation

Note:

PIVOT PRO® foundation requirements are based

on soil pressure of 2500# per square foot. Concrete

pressure recommended for jib crane foundation is 3000#

per square inch of compressive force, with no cracks or

seams in a 48” square area around center of mast.

Note:

Chemical (epoxy) anchor bolts are recommended

because of their ability to withstand the vibrating loads

caused by the rapid raising or lowering of the load.

B) Drill holes in concrete floor using pre-drilled

holes in base plate or

diagram 3C

as a

guide (use drill bit size recommended by

anchor bolt manufacturer).

C) Install anchor bolts (Grade 5 or better) and

hardware (by others) according to

manufacturer’s installation directions and

requirements.

STOP!

Do not proceed if your support structure does not meet the loading requirements determined in

Step 1.4

.

Diagram 3A.

Typical square base plate anchor bolt embed

ment.

Diagram 3C.

Square base plate pattern.

8

9/18

Diagram 3B.

Foundation Requirements.

CONCRETE IS

NORMAL WEIGHT,

STONE AGGREGATE

6”

48” SQ.